Rapid nitridation preparation method of silicon nitride-boron nitride composite ceramic though reactive sintering

A technology of composite ceramics and silicon nitride, which is applied in the field of preparation of reaction sintered silicon nitride-boron nitride composite ceramics, can solve the problems of high heat release, offset cost advantages, and long nitriding time, and achieve good results Flexural strength and fracture toughness, effect of reducing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

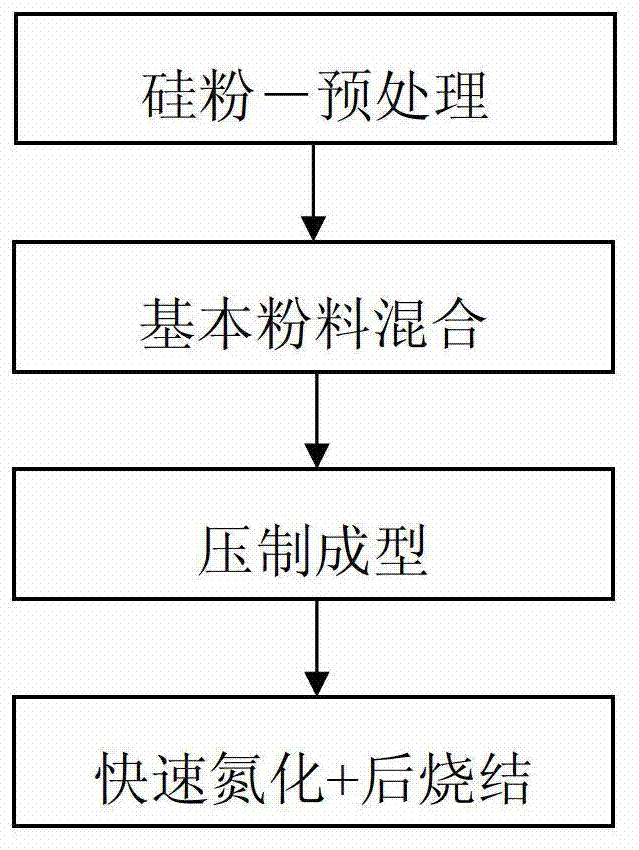

[0017] Such as figure 1 As shown, this embodiment is a rapid nitriding preparation method of reaction sintered silicon nitride-boron nitride composite ceramics. Hydrochloric acid was pickled for 12 hours, then washed with deionized water and dried, and the obtained pre-nitrided silicon powder was mixed with hexagonal boron nitride, zirconia and yttrium oxide powder, and the weight percentage of each component was: silicon 30% 60% of hexagonal boron nitride; 5% of zirconia; 5% of yttrium oxide; then use absolute ethanol whose weight is 1 times that of the basic raw material as the medium for ball milling for 12 hours to obtain a uniformly mixed slurry, and then place the slurry at 60°C Dry in a vacuum drying oven for 8 hours, and then disperse the powder through a 200-mesh sieve, then mold the powder into a green body with a thickness of 5mm in a mold, and process the green body by isostatic pressing at 200MPa; Put the pre-sintered body into the vacuum sintering furnace, quick...

Embodiment 2

[0020] Such as figure 1 As shown, the present embodiment is a rapid nitriding preparation method of reaction sintered silicon nitride-boron nitride composite ceramics, the process is as follows: first, the silicon powder with a median particle size of 15 microns is mixed with dilute hydrochloric acid with a concentration of 10%. Pickling treatment for 12 hours, then cleaning with deionized water and drying, the obtained pre-nitrided silicon powder will be mixed with hexagonal boron nitride, zirconia, yttrium oxide powder, the weight percentage of each component is: silicon 50% ; 40% hexagonal boron nitride; 5% zirconia; 5% yttrium oxide; then use absolute ethanol whose weight is 1 times that of the basic raw material as a medium for ball milling for 12 hours to obtain a uniformly mixed slurry, and then place the slurry at 60 ° C Dry in a vacuum drying oven for 10 hours, and then disperse the powder through a 200-mesh sieve, then mold the powder into a green body with a thickne...

Embodiment 3

[0023] Such as figure 1 As shown, the present embodiment is a rapid nitriding preparation method of reaction sintered silicon nitride-boron nitride composite ceramics. Hydrochloric acid was pickled for 24 hours, then washed with deionized water and dried. The obtained pre-nitrided silicon powder will be mixed with hexagonal boron nitride, zirconia, and yttrium oxide powder. The weight percentage of each component is: silicon 70 %; Hexagonal Boron Nitride 20%; Zirconia 5%; Yttrium Oxide 5%; Then take the dehydrated alcohol that is 2 times of the basic raw material as the medium ball milling for 24 hours to obtain a uniformly mixed slurry, and then the slurry is mixed at 60 Dry in a vacuum drying oven at ℃ for 12 hours, then disperse the powder through a 200-mesh sieve, and then mold the powder into a green body with a thickness of 7mm in a mold, and treat the green body by isostatic pressing at 200MPa; The obtained pre-sintered body was placed in a vacuum sintering furnace, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com