Preparation method of pig lung phospholipid

A technology of porcine lung phospholipids and pig lungs, which is applied in the direction of edible phospholipid compositions, food science, protein food ingredients, etc., can solve the problems of complicated preparation steps and difficult large-scale preparation of porcine lung phospholipids, and achieve the effect of increasing the added value of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

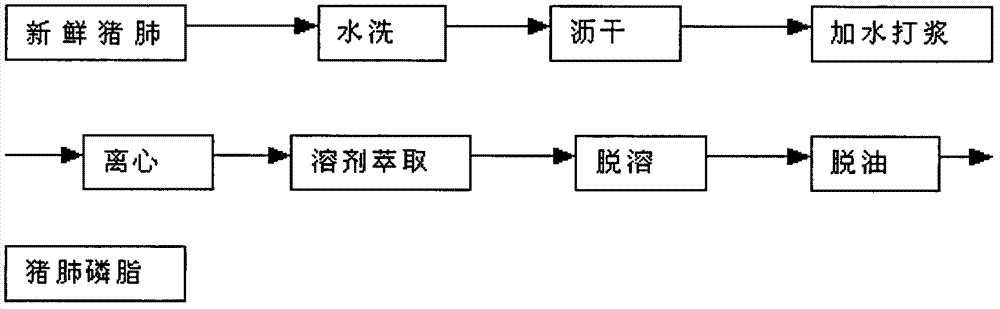

Image

Examples

Embodiment 1

[0018] Add 5,000 grams of freshly washed pig lungs to 15,000 ml of deionized water for beating, pass through a 100-mesh sieve, heat to 35°C, add 250 grams of 1398 protease to react for 2 hours, cool to room temperature, centrifuge to remove slag, and enzymolysis solution Add 20000 milliliters of n-hexane for extraction, separate and obtain the n-hexane layer, desolvate, wash the desolvated matter with acetone until there is no oil, and obtain 10.5 grams of porcine lung phospholipids with a phospholipid content of 91.5%.

Embodiment 2

[0020] Add 5,000 grams of freshly washed pig lungs to 50,000 ml of deionized water for beating, pass through a 100-mesh sieve, heat to 35°C, add 250 grams of 1398 protease to react for 5 hours, cool to room temperature, centrifuge to remove slag, and enzymolysis solution Add 100,000 milliliters of n-hexane for extraction, separate and obtain the n-hexane layer, desolvate, wash the desolvated matter with acetone until there is no oil, and obtain 8.3 g of porcine lung phospholipids with a phospholipid content of 93.1%.

Embodiment 3

[0022] Add 5,000 grams of freshly washed pig lungs to 15,000 ml of deionized water for beating, pass through a 100-mesh sieve, heat to 35°C, add 250 grams of 1398 protease to react for 5 hours, cool to room temperature, centrifuge to remove slag, and enzymatic hydrolysis solution Add 30,000 milliliters of n-hexane for extraction, separate and obtain the n-hexane layer, desolvate, wash the desolvated matter with acetone until there is no oil, and obtain 12.1 g of porcine lung phospholipids with a phospholipid content of 90.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com