Resin modifier and optical film using sugar ester

A technology of resin modifier and sugar ester, applied in the field of resin modifier and optical film, can solve the problems of deterioration of liquid crystal display device, insufficient moisture resistance and compatibility, and achieve high moisture resistance and less variation in optical properties , the effect of excellent characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

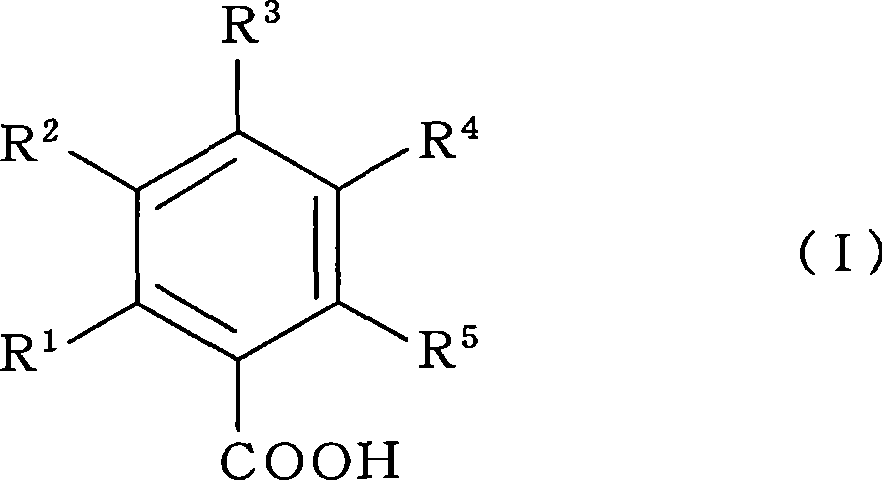

Method used

Image

Examples

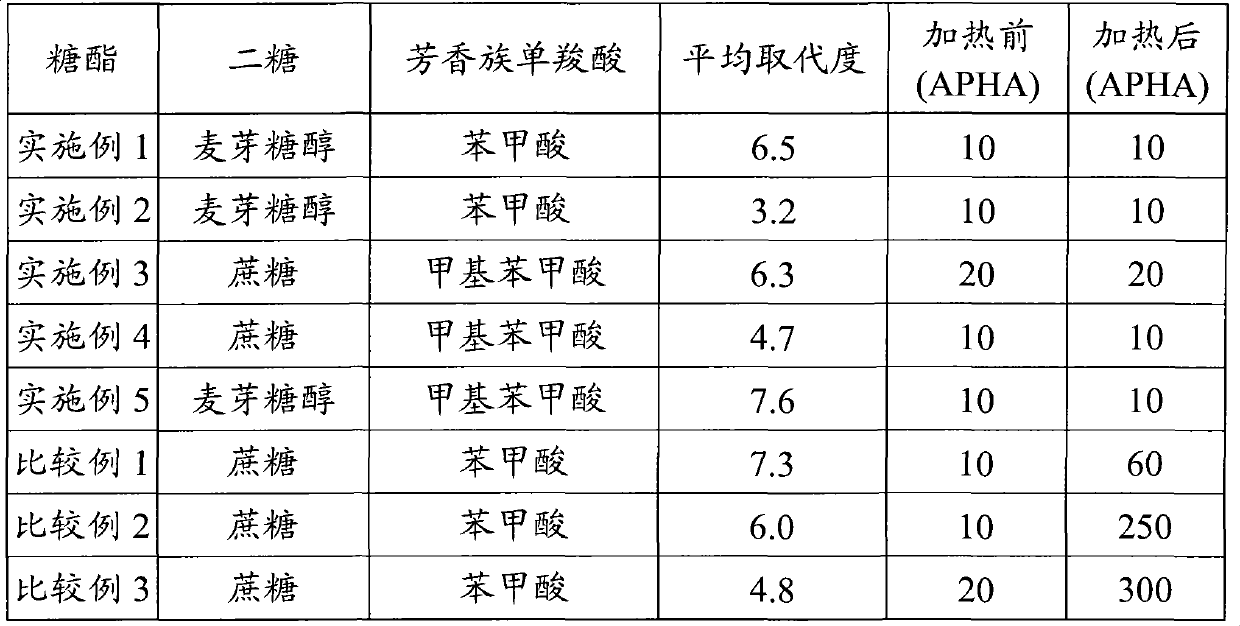

Embodiment 1

[0120]

[0121] Put 30.0 parts of maltitol and 70.0 parts of water into a five-necked flask equipped with a stirring rod, a thermometer, a condenser, a dropping funnel, and a pH electrode connected to a pH meter. After dissolving, cool to below 10°C in a water bath, and simultaneously 100 parts of cyclohexanone containing 79.0 parts of benzoyl chloride were gradually added and dissolved uniformly. While maintaining the temperature below 20°C, 50.1 parts of 48% sodium hydroxide aqueous solution was added from the dropping funnel at such a rate that the pH was maintained at 10-11. The dropwise addition was completed within 1 hour. Thereafter, the water bath was removed, and stirring was continued for 1 hour at a room temperature of 20 to 30° C. for aging to complete the reaction. Thereafter, add a certain amount of sodium carbonate and heat to convert the trace remaining benzoyl chloride into sodium benzoate. Then, the solvent was removed using a rotary evaporator, thereby o...

Embodiment 2

[0123]

[0124] Except having used 30.0 parts of maltitol and 39.0 parts of benzoyl chlorides, it processed similarly to Example 1, and obtained maltitol benzoate. pass 1 The average degree of substitution obtained by H-NMR was 3.2.

Embodiment 3

[0126]

[0127] It processed similarly to Example 1 except having used 30.0 parts of sucrose instead of maltitol, and used 85.3 parts of toluoyl chloride instead of benzoyl chloride, and obtained sucrose methylbenzoate. pass 1 The average substitution degree obtained by H-NMR was 6.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com