Heat-insulation anticorrosive paint for boiler rear smoke channel, preparation method of paint, and paint composition

A tail flue and anti-corrosion coating technology, applied in anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of wasting manpower, material and financial resources, and inconvenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Ceramic beads: 28%, silicon carbide: 30%, boron nitride: 25%, fine-grained alumina: 4%, ultra-fine zinc oxide: 3%, titanium oxide: 7%, yttrium trioxide: 3%.

[0020] Coating step: the above-mentioned prepared coating and the base film substance are mixed with a weight ratio of 15:1 to prepare a coating composition, wherein the base film substance comprises 50% aqueous alkali metal silicate solution and 50% colloidal diacetate by weight percentage Aqueous dispersion of silicon oxide. When painting, mix the coating composition and curing agent (organic resin curing agent) at a ratio of 10:1 (weight ratio). When mixing, the paint should be stirred continuously and the curing agent should be slowly incorporated. Then filter the mixed paint with a 40-mesh sieve to make the paint in a suspended state, and the coating needs to be completed within 4 hours, so as to complete the preparation of the coating.

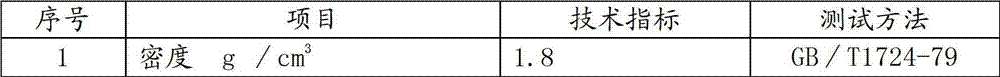

[0021] For the coating that embodiment 1 makes, carry out following pe...

Embodiment 2

[0025] Ceramic beads: 28%, silicon carbide: 23%, boron nitride: 30%, fine-grained alumina: 5%, ultra-fine zinc oxide: 5%, titanium oxide: 8%, yttrium trioxide: 1%.

[0026] Coating step: the paint prepared above and the base film substance are mixed with a weight ratio of 15:1 to make a coating composition, wherein the base film substance comprises 85.5% aqueous alkali metal silicate solution and 14.5% colloidal diacetate by weight percentage Aqueous dispersion of silicon oxide. When painting, mix the coating composition and curing agent (organic resin curing agent) at a ratio of 10:1 (weight ratio). When mixing, the paint should be stirred continuously and the curing agent should be slowly incorporated. Then filter the mixed paint with a 40-mesh sieve to make the paint in a suspended state, and the coating needs to be completed within 4 hours, so as to complete the preparation of the coating.

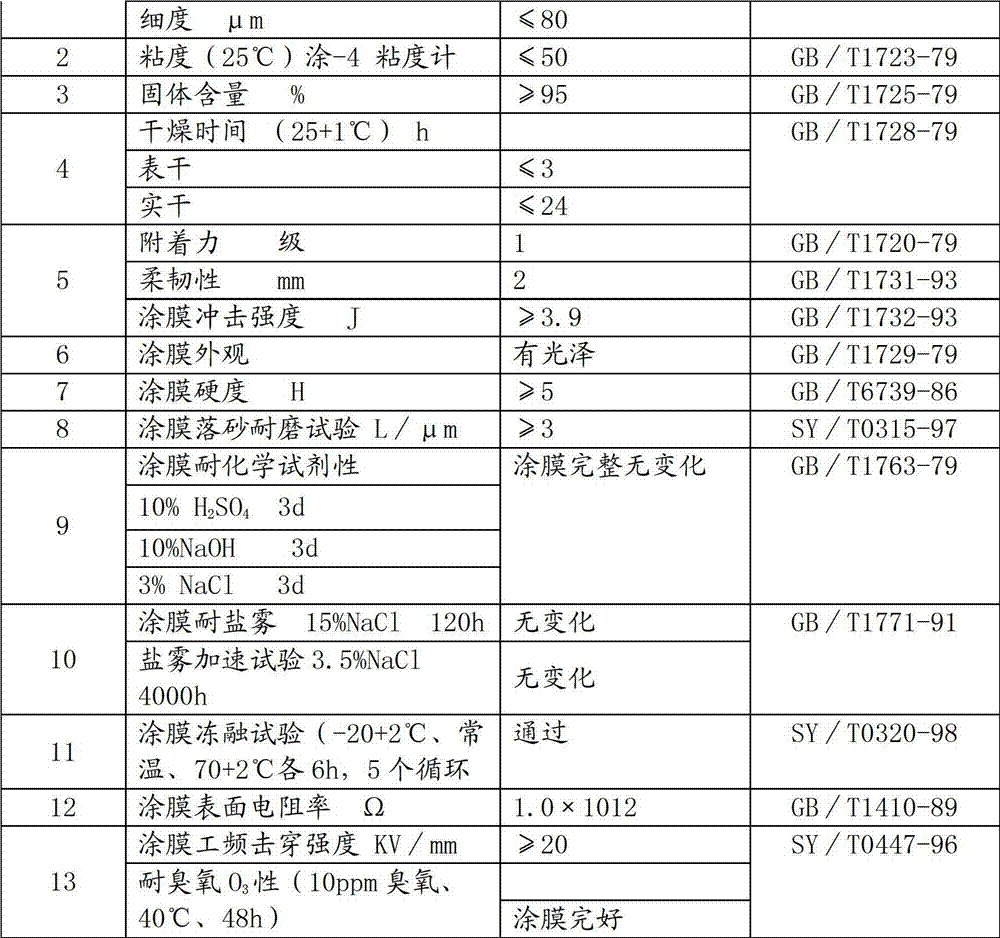

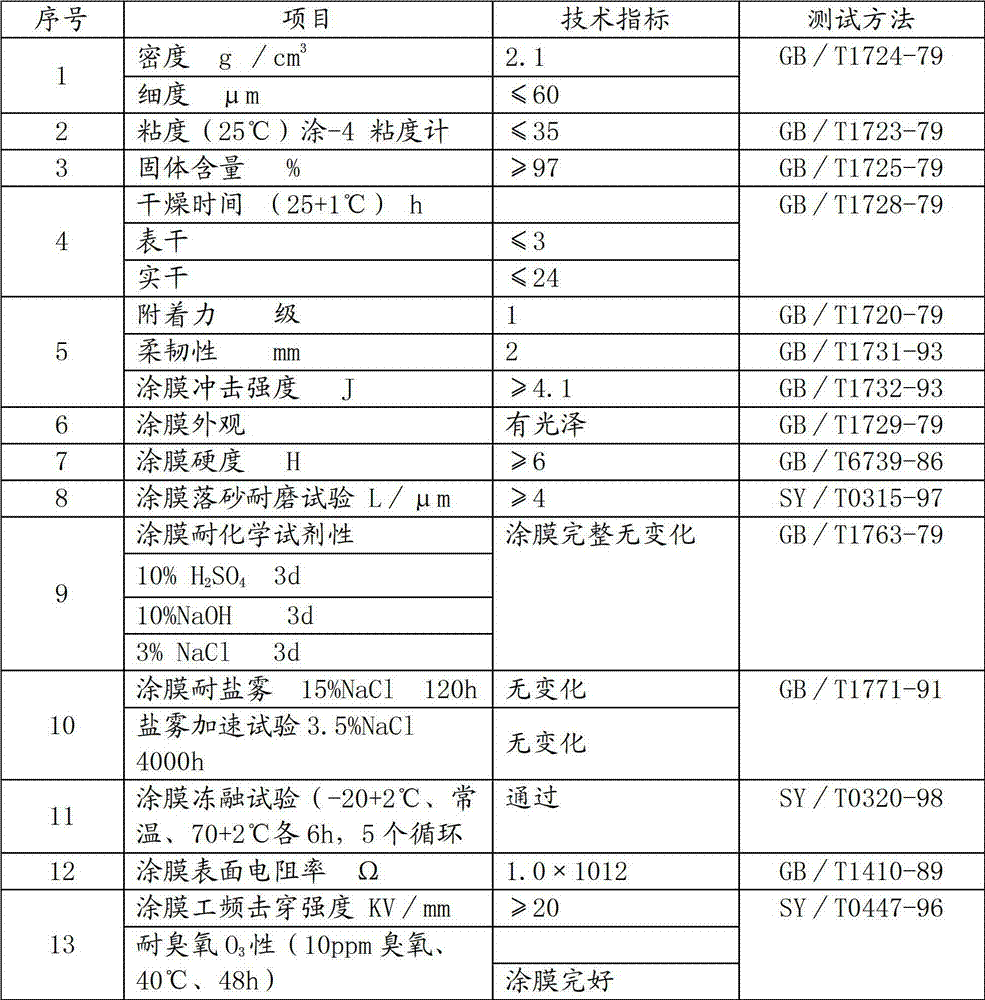

[0027] For the coating that embodiment 2 makes, carry out following performance t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com