Solid glass cleaner and processing method thereof

A processing method and cleaning agent technology, applied in the direction of chemical instruments and methods, detergent materials, detergent compositions, etc., can solve the problems of inconvenient product transportation and carrying, and achieve light weight, reduced consumption, and low transportation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

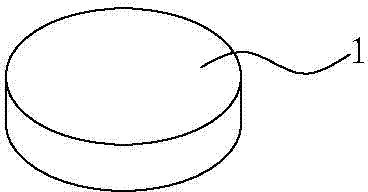

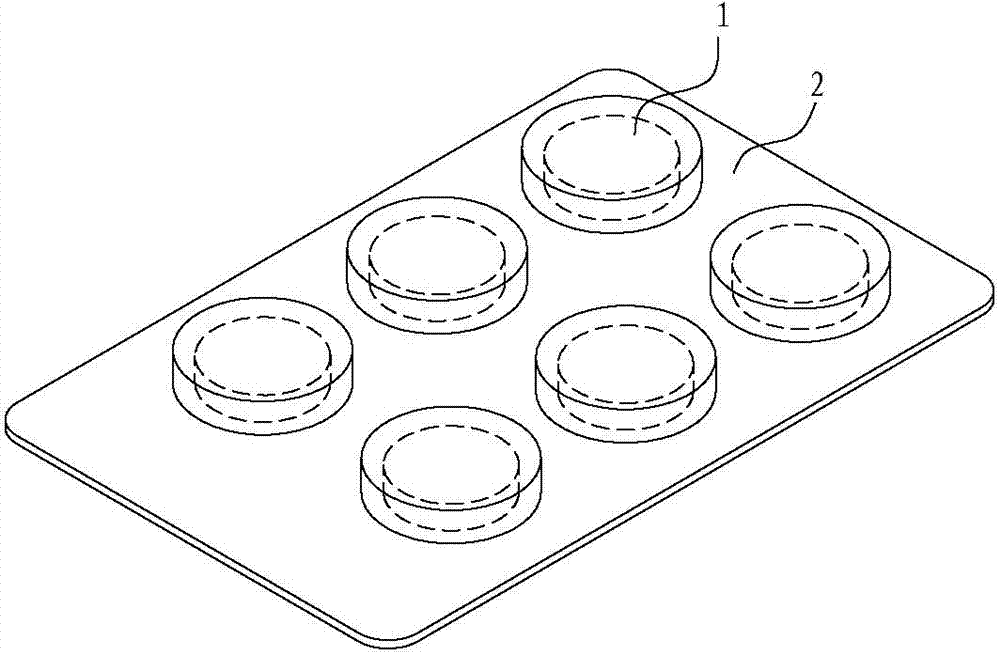

[0037] Such as figure 1 As shown, it is a schematic structural diagram of a solid glass cleaner 1 according to the present invention. The solid glass cleaner 1 is granular, specifically a flat cylinder or special-shaped cylinder with a diameter of 18.5-20 mm and a thickness of 8.3-9 mm. .

[0038] Specifically, the solid glass cleaner 1 is compressed into granules after the following components are evenly stirred, and the components include: sodium dodecylbenzenesulfonate, 43-45wt%; sodium sulfate, 8-10wt%; Tetrol, 8-10wt%; Sodium hydroxide, 0.5-1wt%; Sodium silicate, 2-3wt%; Dextrin, 2-3wt%; Food coloring, 0.5-1wt%; Baking soda, 8-10wt%; Citric acid granules, 8-10wt%; Borax, 3-5wt%; Propylene glycol, 3-4wt%. Using the above components can also increase the speed at which the entire solid glass cleaner 1 dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com