Method for producing nutrition sugar by sugar producing material

A technology of nutritious sugar and materials, applied in confectionery, confectionary industry, food science, etc., can solve problems such as difficult to achieve, ineffective use of materials, low efficiency, etc., and achieve the effect of increasing surface active organic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

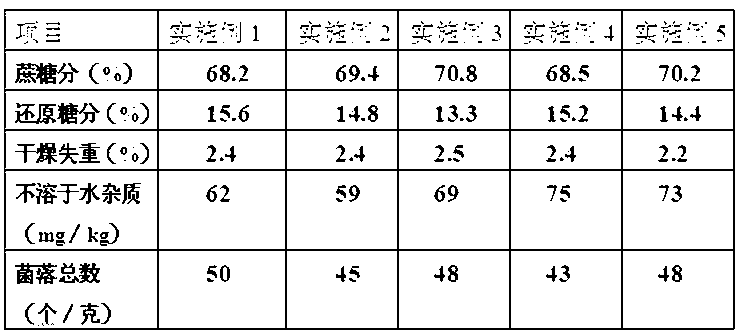

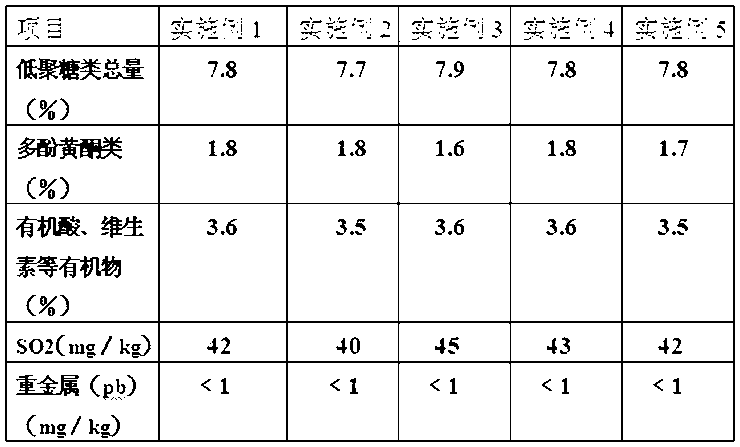

Embodiment 1

[0021] This example is based on the common sulfite sugar production process using sugarcane as raw material, including the raw sugarcane juice extraction, clarification, evaporation, sugar boiling, crystallization, honey separation and drying processes. The cleaning treatment method for the boiled sugar material is: add the ethyl sugar paste with a purity of 46.5Ap into the 40m 3 Dilute the diluted honey to 63.0Bx with 65°C sugar process water, then heat the diluted honey to 78~80°C with steam to flow into the floater, and pass compressed air into the heated honey to froth and float , clear out the floating foam; add the honey that has cleared the foam into the fast settler, add 1200ppm phosphoric acid and 1300ppm calcium hydroxide into the fast settler to form calcium hydrogen phosphate-calcium phosphate network sedimentation, and add 3.5ppm to the fast settler at the same time The flocculant assists the adsorption of suspended particles and impurities to settle, and the puri...

Embodiment 2

[0023] This example is based on the common sulfite sugar production process using sugarcane as raw material, including the raw sugarcane juice extraction, clarification, evaporation, sugar boiling, crystallization, honey separation and drying processes. The cleaning treatment method for the boiled sugar material is: add the second-washed honey stream with a purity of 46.0Ap, which is sieved out of the sugar syrup through the nectar separation, into the 40 m 3 Dilute the diluted honey to 62.5Bx with 65°C sugar process water, then heat the diluted honey to 70~72°C with steam to flow into the floater, and use compressed air to blow into the heated honey for foaming and floating , clear out the floating foam; add the honey that has cleared the foam into the fast settler, flow into the fast settler with 1000ppm phosphoric acid and 1200ppm calcium hydroxide to form calcium hydrogen phosphate-calcium phosphate network sedimentation, and add 2.5ppm to the fast settler at the same time ...

Embodiment 3

[0025] This example is based on the common sulphite sugar production process using sugarcane as raw material, including the raw material sugarcane juice extraction, clarification, evaporation, three-line sugar cooking, crystallization, honey separation and drying processes. The cleaning treatment method for the boiled sugar material is: add the second washed honey stream with a purity of 50.3Ap, which is obtained by sifting out the sugar syrup through nectar separation, into the 40 m 3 Dilute it to 70.0Bx with 65°C sugar process water, then heat the diluted honey to 78~80°C with steam to flow into the floater, and use compressed air to flow into the heated syrup to foam and float , clear out the floating foam; add the honey that has cleared the foam into the fast settler, flow into the fast settler with 800ppm phosphoric acid and 900ppm calcium hydroxide to form calcium hydrogen phosphate-calcium phosphate network sedimentation, and add 4.5ppm to the fast settler at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com