Preparation method of micro/nanofiber sustained release preparation

A nanofiber and sustained-release preparation technology, applied in the field of biomedicine, can solve the problems that the electrospinning fiber film is difficult to achieve long-term drug release, the specific surface is too large, etc., and achieves the effect of long release time, less drug amount, and improved curative effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 2g of IBU and completely dissolve it in 100mL of n-hexane, weigh 4g of modified mesoporous silica nanoparticles (MMS) and add them to the IBU solution, incubate at 37°C for 24h, centrifuge, take the solid and dry to obtain MMS-IBU nanoparticles;

[0039] Disperse MMS-IBU nanoparticles in a mixed solvent of ethanol and hexafluoroisopropanol (HFIP), weigh 40g of poly-L-lactic acid (PLLA) and dissolve it in DCM, mix the two solutions, and control the PLLA content to 22 wt%;

[0040] Electrospinning to obtain ibuprofen micro / nanofiber sustained-release preparation (PLLA-MMS-IBU). Among them, the electrospinning process parameter conditions are: voltage 11kV, flow rate 0.04mL / min, and the distance between the receiving table and the spinneret is 15cm.

[0041] PLLA-IBU (with an IBU content of 9 wt%) and electrospun PLLA were prepared by the same preparation process.

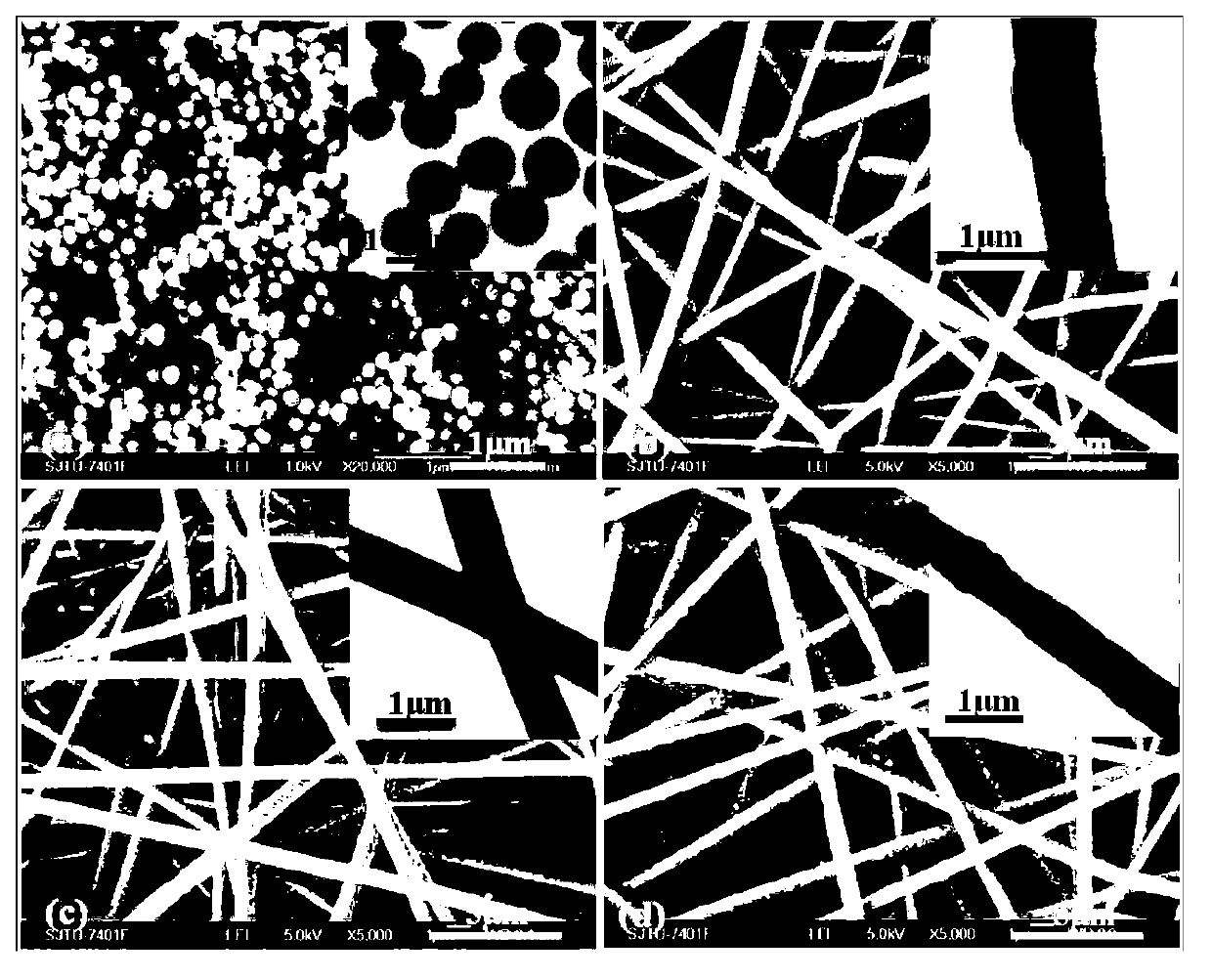

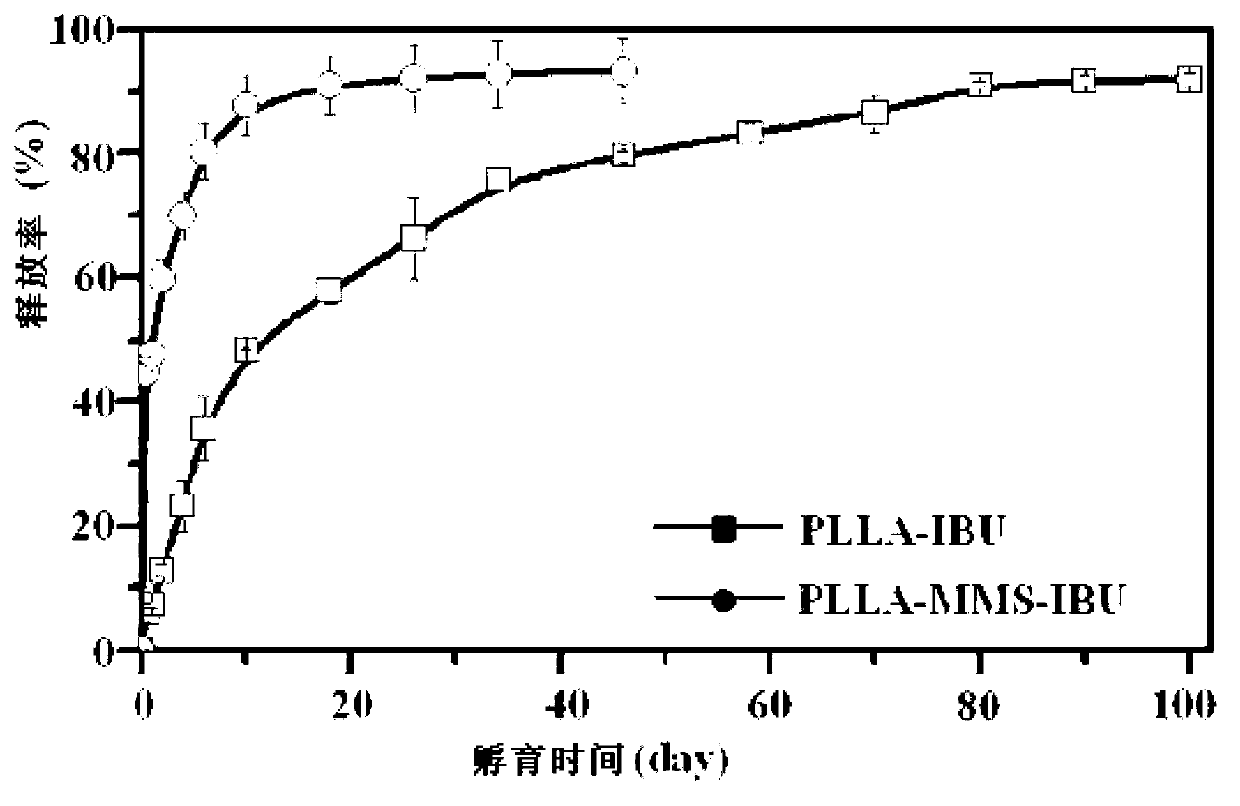

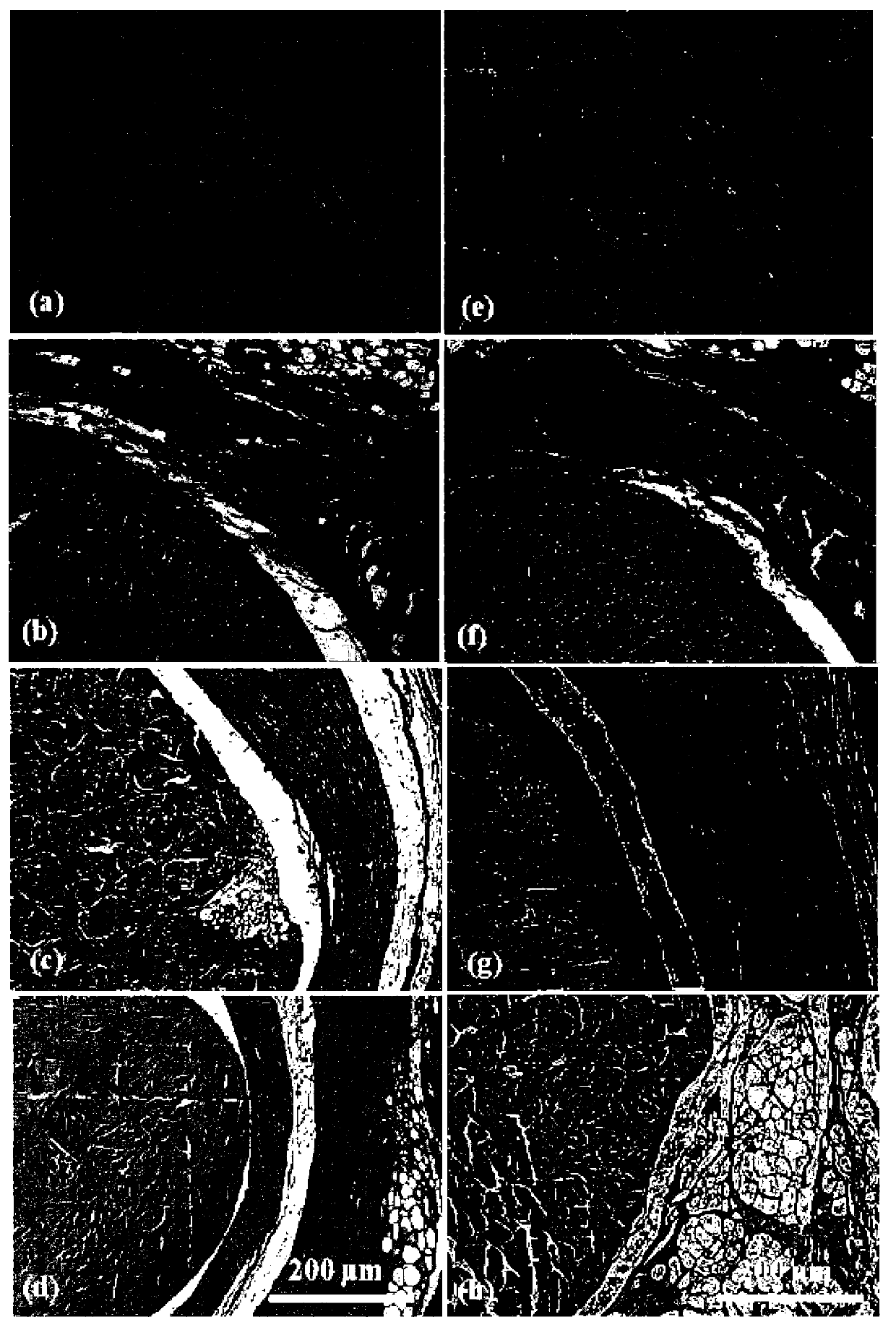

[0042] Scanning electron microscope (SEM) and transmission electron microscope (TEM) observed the obt...

Embodiment 2

[0047] Weigh 2g of IBU completely dissolved in 100mL of n-hexane, weigh 3g of modified mesoporous silica nanoparticles (MMS) into the IBU solution, incubate at 37°C for 24h, centrifuge, take the solid and dry to obtain MMS-IBU nanoparticles;

[0048] Disperse MMS-IBU nanoparticles in a mixed solvent of ethanol and HFIP, weigh 38g poly-L-lactic acid (PLLA) and dissolve it in DCM, mix the two solutions, and control the PLLA content to 22 wt%;

[0049] Electrospinning to obtain ibuprofen micro / nanofiber sustained-release preparation (PLLA-MMS-IBU). Among them, the electrospinning process parameter conditions are: voltage 11kV, flow rate 0.04mL / min, and the distance between the receiving table and the spinneret is 15cm.

Embodiment 3

[0051] Weigh 2.2g of IBU and completely dissolve it in 100mL of n-hexane, weigh 4g of modified mesoporous silica nanoparticles (MMS) and add them to the IBU solution, incubate at 37°C for 24h, centrifuge, take the solid and dry to obtain MMS-IBU nanoparticles;

[0052] Disperse the MMS-IBU nanoparticles in the mixed solvent of ethanol and HFIP, weigh 40g poly-L-lactic acid (PLLA) and dissolve it in DCM, mix the two solutions, and control the PLLA content to 22 wt%;

[0053] Electrospinning to obtain ibuprofen micro / nanofiber sustained-release preparation (PLLA-MMS-IBU). Among them, the electrospinning process parameter conditions are: voltage 11kV, flow rate 0.04mL / min, and the distance between the receiving table and the spinneret is 15cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com