Method for extracting perillaseed hydrophilic chemical component from perillaseed oil residue

A chemical composition, hydrophilic technology, applied in the directions of medical preparations containing active ingredients, non-central analgesics, plant/algae/fungus/moss ingredients, etc. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

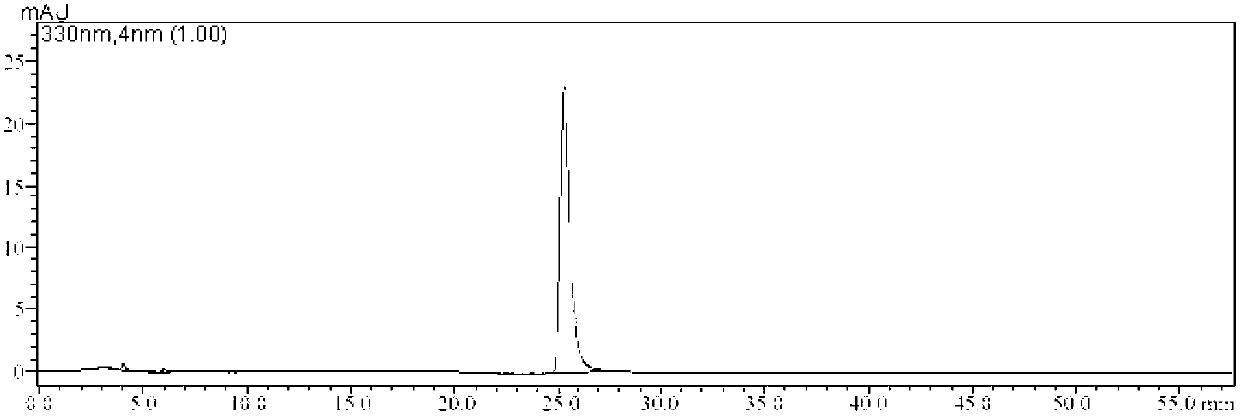

[0026] Embodiment 1, extract rosmarinic acid from perilla oil residue

[0027] Take perilla oil residue 2kg, dry at 40-50°C, use ethanol aqueous solution with a volume fraction of 20% as the extractant, and soak in a constant temperature water bath at 80°C according to the material-to-solvent ratio of 1:30 (kg / L, w / v). Extract 2 times, 1h each time, and combine the extracts. Use 18% hydrochloric acid solution to adjust the pH value of the extract between 2.0-2.5, add ethyl acetate to extract 3 times according to the ratio of solid to liquid to solvent 5:3 (v / v), combine the extracts, and concentrate under reduced pressure , that is, the total extract of the hydrophilic components of perilla oil residue. Methanol was settled to 50mL, and the rosmarinic acid yield of 0.52% was measured by high performance liquid chromatography (the yield was calculated according to "the amount of rosmarinic acid / the quality of perilla oil residue", and the content determination method was with ...

Embodiment 2

[0028] Embodiment 2, extract rosmarinic acid from perilla oil residue

[0029] Get perilla oil residue 0.5kg, 40-50 ℃ of oven dry, be the mixed solvent that the volume ratio of 95% ethanol aqueous solution and alkali water (the borax aqueous solution of mass content 0.2%) volume ratio is 8: 2 is extraction agent, according to The ratio of material to solvent was 1:6 (kg / L, w / v), heated to reflux for 2 hours, filtered, and the filter residue was further refluxed and extracted with the above extractant for 3 times, each time for 1 hour, and the filtrates were combined and concentrated under reduced pressure. Use hydrochloric acid with a mass fraction of 18% to adjust the pH value of the concentrated solution to 4.5-5.0, then extract once with an equal volume of petroleum ether, discard the petroleum ether part; continue to adjust the pH value of the remaining solution to 3.0-3.5, and so on Extract 2 times with volumetric ethyl acetate, collect the ethyl acetate extract; adjust t...

Embodiment 3

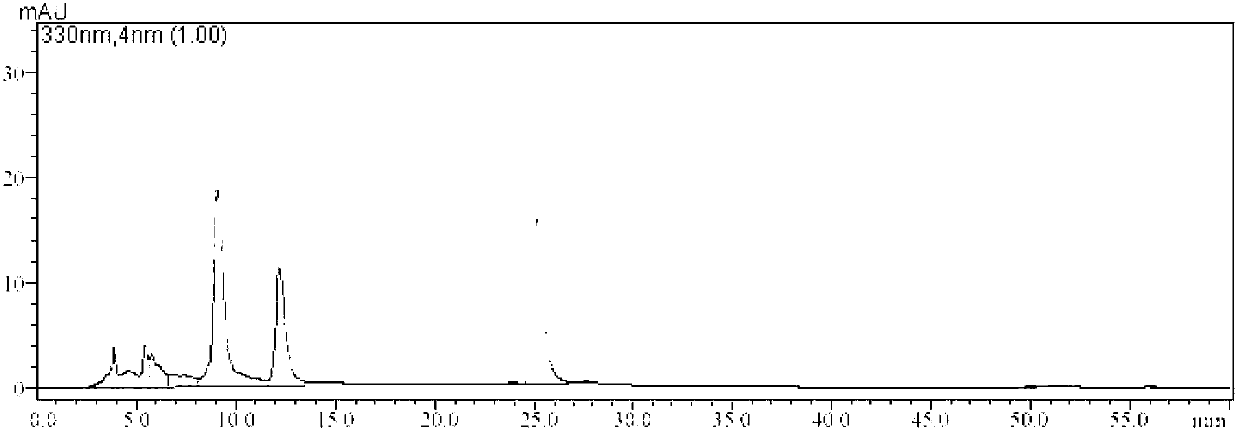

[0030] Embodiment 3, extract rosmarinic acid from wild perilla seed (adulterated product, containing perilla seed) oil residue

[0031] Take 0.5kg of perilla oil residue, dry at 40-50°C, use a mixture of water-ethanol-1M hydrochloric acid (20:80:1, v / v / v) as the extractant, and use a material-to-solvent ratio of 1:30 ( kg / L, w / v), cold soaked overnight. Filter and collect the filtrate. Add the above extractant to the filter residue and continue to heat and reflux for extraction for 2 hours. The material-to-solvent ratio is 1:6 (kg / L, w / v). The combined filtrates were concentrated under reduced pressure. Extract once with an equal volume of petroleum ether, and discard the petroleum ether part. Then extract twice with ethyl acetate and n-butanol respectively, and combine the extracts. Concentrate under reduced pressure to obtain the total extract of the hydrophilic components of perilla oil residue. Methanol was fixed to 25mL, and the yield of rosmarinic acid was measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com