A method and system for treating acid gas

A technology of acidic gas and gas, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of high sewage treatment costs, high one-time investment costs, and rising treatment costs, and achieve neutralization Effects of capacity improvement, energy consumption reduction, and capacity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

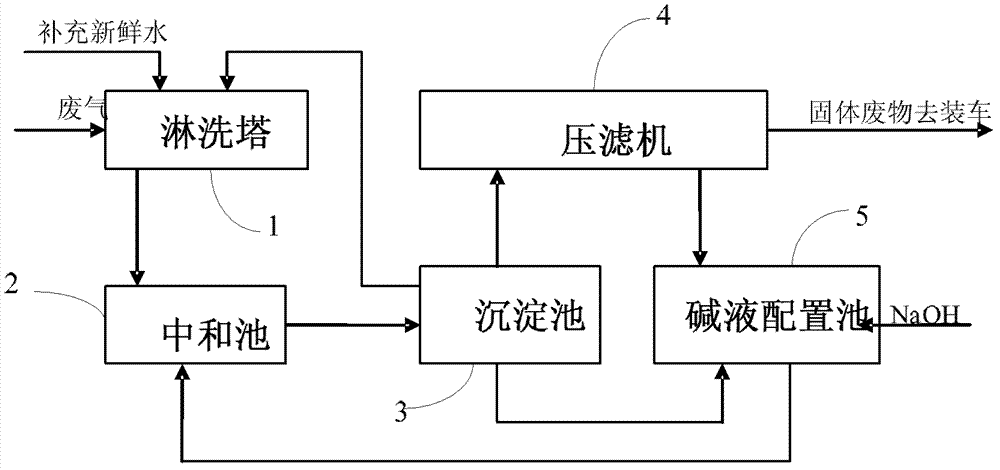

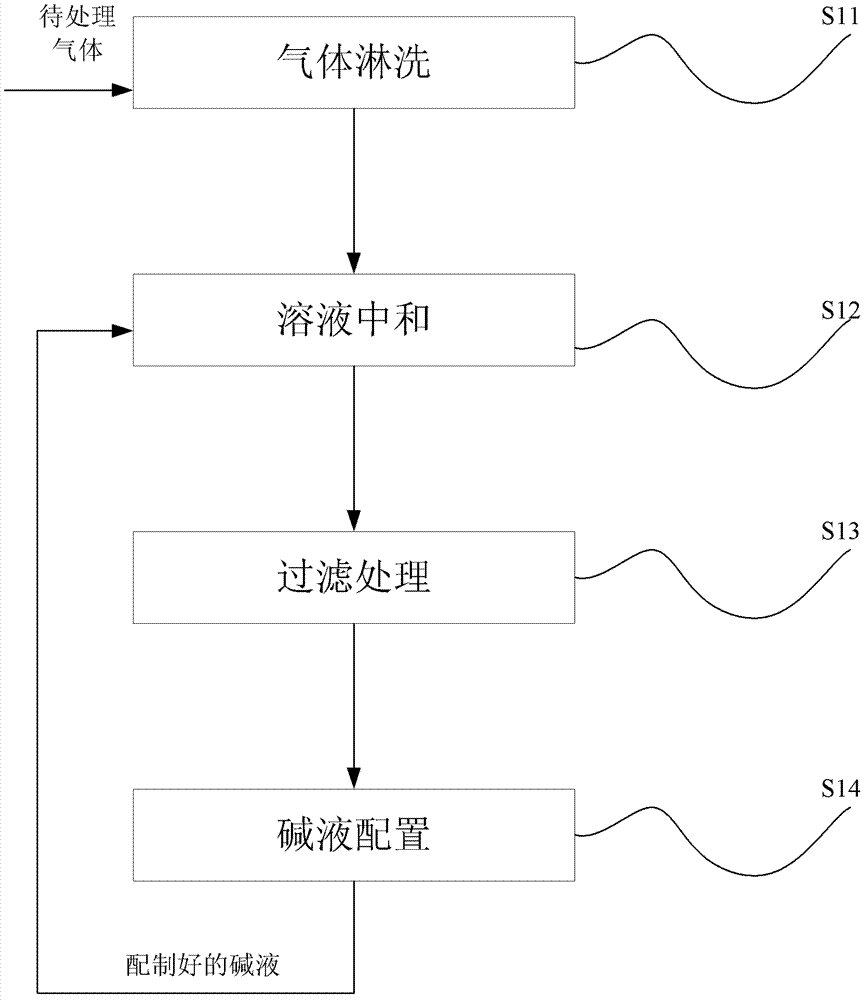

[0028] Please refer to the attached figure 1 And attached image 3 , with figure 1 It is the flow chart of the specific embodiment 1 of the acid gas treatment method disclosed in the present invention, wherein the labels 1-5 are respectively the leaching tower, the neutralization tank, the sedimentation tank, the filter press, the lye configuration tank, and the attached image 3 It is a flowchart of the acid gas treatment method disclosed in the present invention, including steps:

[0029] S11: gas leaching;

[0030] The waste gas produced in the polysilicon production process is passed into the leaching tower for gas rinsing. The leaching tower adopts the countercurrent operation of gas and liquid so that the gas can be fully absorbed. During this stage, HCl is absorbed into the liquid phase and the chlorosilane component reacts with water to form SiO 2 and HCl, into the wastewater system. Wherein the reaction equation of chlorosilane is:

[0031] SiHCl 3 +3H 2 O=H2S...

specific Embodiment 2

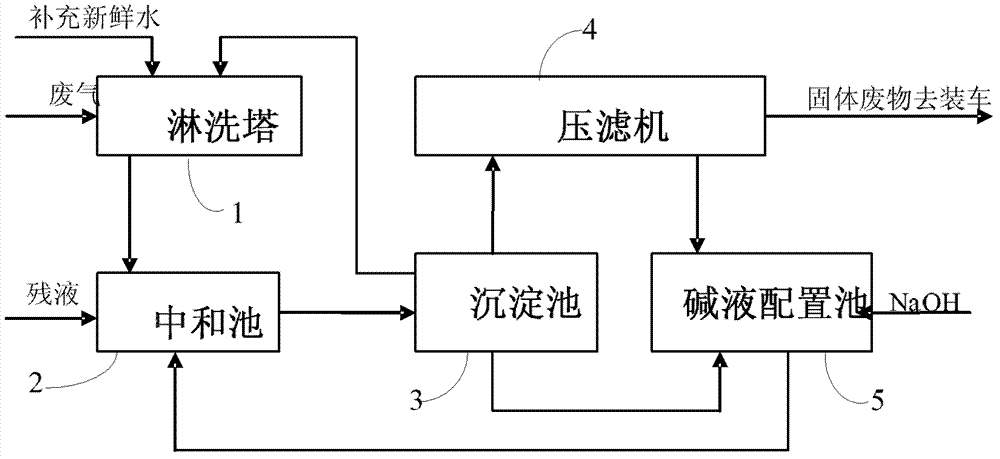

[0046] The present invention also includes another specific implementation mode, please refer to the attached figure 2 And attached image 3 , with figure 2 It is the specific flow chart of the present embodiment, and the labels 1-5 are respectively the leaching tower, the neutralization tank, the sedimentation tank, the filter press, the lye configuration pool, and the attached image 3 It is a flowchart of the method of the present invention. Include steps:

[0047] S11: gas leaching;

[0048] The waste gas produced in the polysilicon production process is passed into the leaching tower for gas rinsing. The leaching tower adopts the countercurrent operation of gas and liquid so that the gas can be fully absorbed. During this stage, HCl is absorbed into the liquid phase and the chlorosilane component reacts with water to form SiO 2 and HCl, into the wastewater system. Wherein the reaction equation of chlorosilane is:

[0049] SiHCl 3 +3H 2 O=H2SiO 3 +3HCl+H 2 ↑ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com