Cellulose acetate foamed porous material and supercritical carbon dioxide auxiliary processing method thereof

A technology of cellulose acetate and cellulose diacetate, which is applied in the field of cellulose acetate foamed porous materials and supercritical carbon dioxide auxiliary processing, can solve the problems of environmental hazards, poor spinnability, and slow spinning speed, and achieve filtration efficiency Improvement, low price, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0045] A kind of cellulose acetate foaming porous material, its formula is as shown in table 1:

[0046] Table 1:

[0047] Example

[0048] Put cellulose acetate, plasticizer, stabilizer, lubricant, and adsorbent into a high-speed mixer according to the proportions in the above table and mix for 3 to 5 minutes, then add them to the hopper of the extruder for extrusion processing, and at the same time in the extruder The blowing agent supercritical carbon dioxide is injected into the injection port in proportion, and after being fully mixed by the foaming extruder, the foaming is extruded from the die and formed; the special extruder is a single-screw or parallel twin-screw with 5 heating zones The extruder has a static mixer with 5 to 8 sections at the output end of the extruder; the screw element is provided with a flight parallel to the thread direction; the metering section of the extruder is provided with an injection port for liquid carbon dioxide . The inject...

experiment example 1

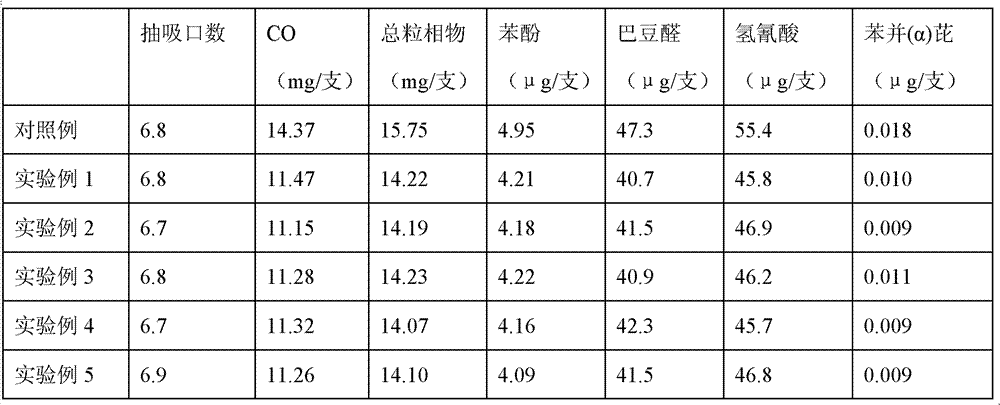

[0053] Control group: 100 cigarettes were prepared using No. 1 shredded tobacco, cigarette paper, and ordinary cigarette filter rods from China Tobacco Anhui Co., Ltd.

[0054] Experimental groups 1 to 5: Cigarette filter rods prepared from No. 1 shredded tobacco and cigarette paper from China Tobacco Anhui Co., Ltd., and the cellulose acetate porous foam material prepared in Examples 1 to 5 of the present invention (prepared to be mixed with ordinary cellulose 100 cigarettes prepared by tow filter (with the same specifications);

[0055] Cigarette smoke analysis test: according to GB / T 19609-2004 "Determination of total particulate matter and tar by smoking machine for routine analysis of cigarettes" and GB / T 23356-2009 "Determination of carbon monoxide in gas phase of cigarette smoke by non-scattering infrared emission" Determination of total particulate matter (PTM), tar and carbon monoxide content in smoke, and determination of benzo(α)pyrene in mainstream smoke according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com