Method for preparing crack-free photonic crystal on surface of super-hydrophobic organism or super-hydrophobic imitation organism

A super-hydrophobic imitation, photonic crystal technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of unsolved high-stacking crystal plane cracks, lack of universality, and potential safety hazards. Avoid diffuse reflection effect, peak intensity increase, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

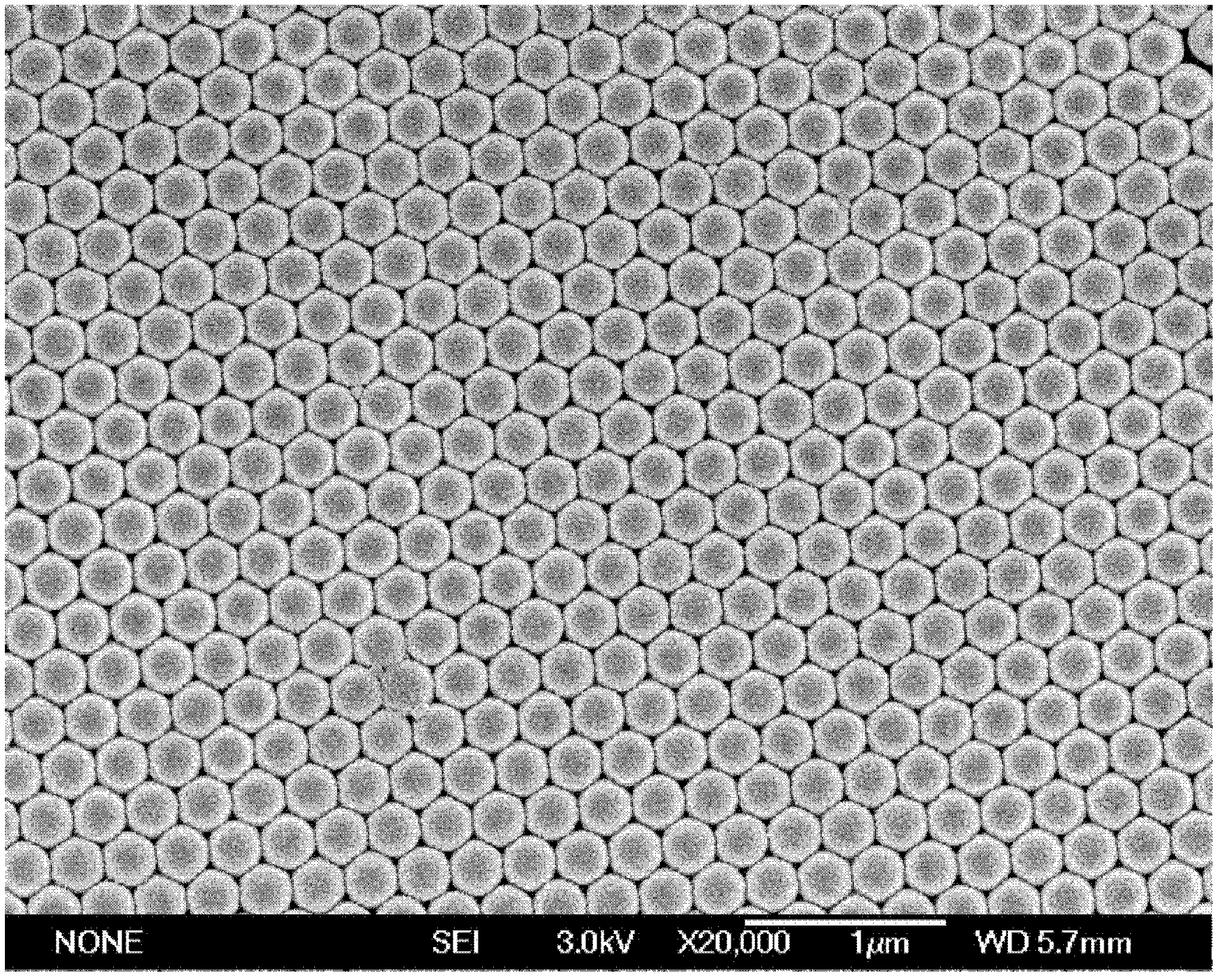

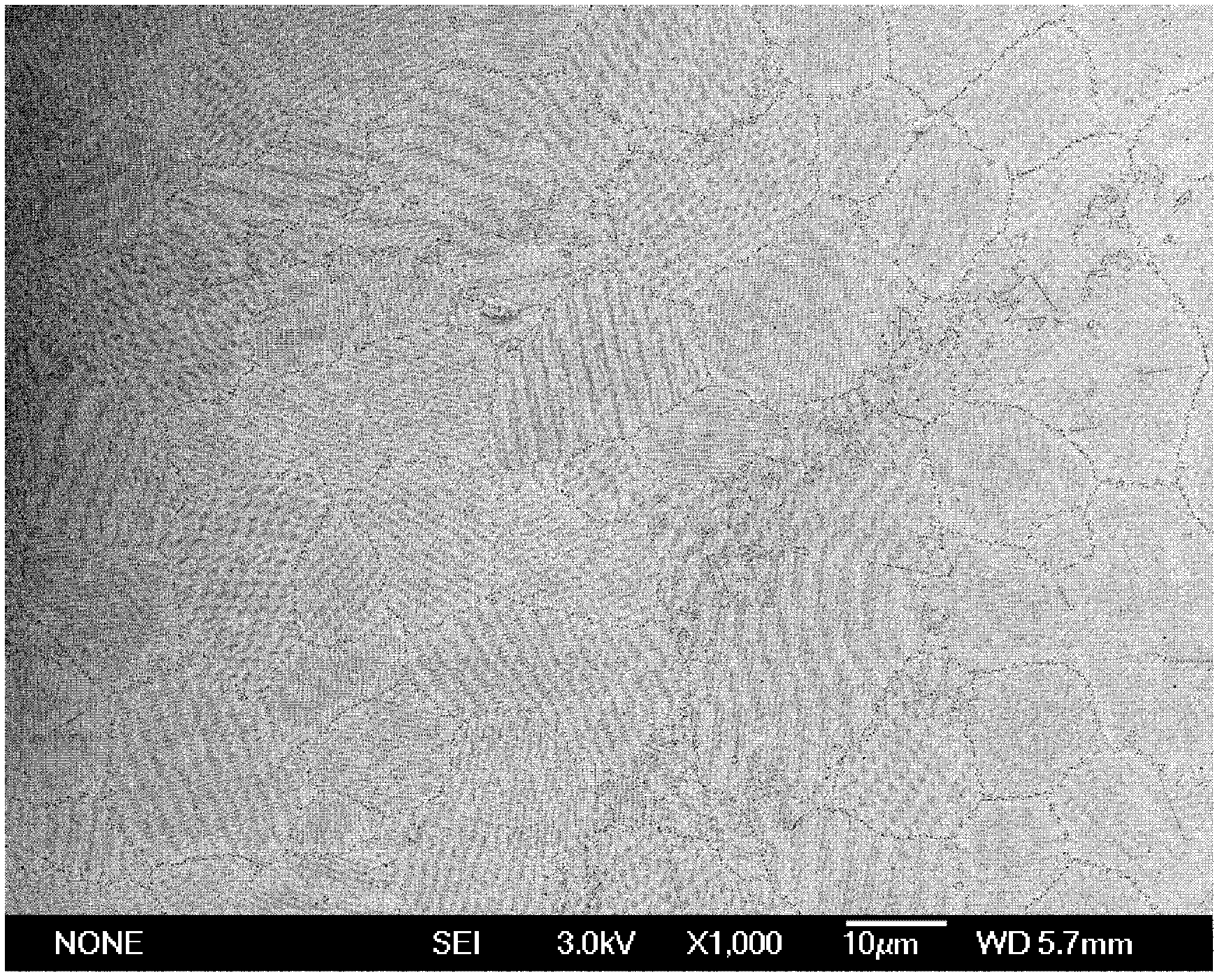

[0028]The monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particles with a particle diameter of 80nm are ultrasonically dispersed in water to form an emulsion (the concentration of the emulsion is 0.01wt%), and the resulting emulsion is heated at a temperature of 5°C , humidity is placed on the surface of lotus leaf (the contact angle of the surface of lotus leaf and water is 145 °) under the condition of 5%, by the described monodisperse poly (styrene-methyl methacrylate-acrylic acid) latex particle The self-gravity effect of the self-assembled self-assembled self-assembled poly(styrene-methyl methacrylate-acrylic acid) latex particles formed by the self-assembly of the monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particles is prepared on the surface of the lotus leaf. Crack-free opal-structured triblock copolymer poly(styrene-methyl methacrylate-acrylic acid) photonic crystals.

[0029] The high-quality self-supporting non-crack opal tr...

Embodiment 2

[0031] The monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particles with a particle diameter of 1100nm are ultrasonically dispersed in water to form an emulsion (the concentration of the emulsion is 30wt%). Humidity is placed on the surface of the rice leaf under the condition of 95% (the contact angle of the surface of the rice leaf and water is 135 °), by the described monodisperse poly (styrene-methyl methacrylate-acrylic acid) latex particles Self-gravity is deposited, and the photon band gap formed by the self-assembly of the monodisperse poly(styrene-methyl methacrylate-acrylic acid) latex particles is prepared on the surface of the rice leaf. Cracked opal-structured poly(styrene-methyl methacrylate-acrylic acid) photonic crystals.

[0032] The high-quality self-supporting poly(styrene-methyl methacrylate-acrylic acid) photonic crystal prepared above was used as a sacrificial template, and the TiO 2 The sol is filled into the gap between the monodispe...

Embodiment 3

[0034] Ultrasonic dispersion of monodisperse polystyrene latex particles with a particle size of 1100nm in water forms an emulsion (the concentration of the emulsion is 30wt%), and the resulting emulsion is placed in a butterfly under the condition that the temperature is 60°C and the humidity is 60%. The surface of the wing (the contact angle between the surface of the butterfly wing and water is 130 °), is deposited by the self gravity of the monodisperse polystyrene latex particles, and the surface of the butterfly wing is prepared by the monodisperse High-quality self-supporting non-crack opal structure polystyrene photonic crystals with photonic band gap formed by polystyrene latex particles self-assembly.

[0035] The high-quality self-supporting polystyrene photonic crystal with no crack opal structure prepared above was used as a sacrificial template, and the TiO 2 The sol is filled into the gaps between the monodisperse polystyrene latex particles constituting the sac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com