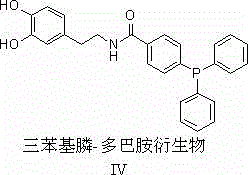

Preparation method of magnetic nano triphenylphosphine catalysis ligand

A magnetic nano and triphenylphosphine technology, applied in chemical instruments and methods, carbon monoxide reaction preparation, physical/chemical process catalysts, etc., to achieve the effects of improving catalytic activity, uniform size distribution, and improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the synthesis of ferric oleate

[0018] Synthesize iron oleate according to the method of T. Hyeon et al. (Nature Mater. 2004, 3, 891~895), the specific method is as follows: take 2.71 g FeCl 3 ·6H 2 O and 9.13 g of sodium oleate were mixed in a mixed solvent of 20 mL of ethanol, 15 mL of distilled water and 35 mL of n-hexane. The resulting mixture was stirred and reacted at 70 °C for 4 h, and the organic phase was separated, and the organic phase was washed with distilled water (3 ×10 mL), and then evaporated the solvent under reduced pressure with a rotary evaporator to obtain 9.12 g of dark brown viscous product iron (I) oleate.

Embodiment 2

[0019] Example 2: Preparation of Magnetic Nano Iron Oxide Particles by Thermal Decomposition

[0020] Refer to the method of T. Hyeon et al. (Nature Mater. 2004, 3, 891~895) to prepare magnetic nano-iron oxide particles. The specific method is as follows:

[0021] 9.12 g iron(I) oleate was dissolved in 41.1 g 1-octadecene and 1.17 g oleic acid was added, the resulting mixture was heated from room temperature to 340 °C at a rate of 3 °C / min and kept for 40 min, followed by the reaction The mixture was naturally cooled to room temperature to obtain a dark brown 1-octadecene solution of magnetic nano-iron oxide particles (II).

Embodiment 3

[0022] Embodiment 3: the pretreatment of magnetic nanometer iron oxide particle

[0023] Take 10 mL of 1-octadecene solution of magnetic nano-iron oxide particles (II), first wash with 95% ethanol (3×20 mL) to remove the solvent 1-octadecene, and then wash with 1:1 volume ratio of chloroform / Magnetic nano-iron oxide particles (3×10 mL) were washed with acetonitrile mixed solvent to remove excess oleic acid and irregular non-spherical nanoparticles to obtain relatively uniform magnetic nano-iron oxide particles (III) (diameter ~15 nm). The pretreated magnetic iron oxide nanoparticles (III) were stored in 5 mL chloroform until use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com