Method for simultaneously extracting vanadium, aluminum and potassium from stone coal

A technology from vanadium stone coal and vanadium stone, which is applied in the field of extracting vanadium pentoxide, can solve the problems of poor resource utilization, low total recovery rate, and low recovery rate, and achieve the goals of protecting the environment, simplifying the process, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

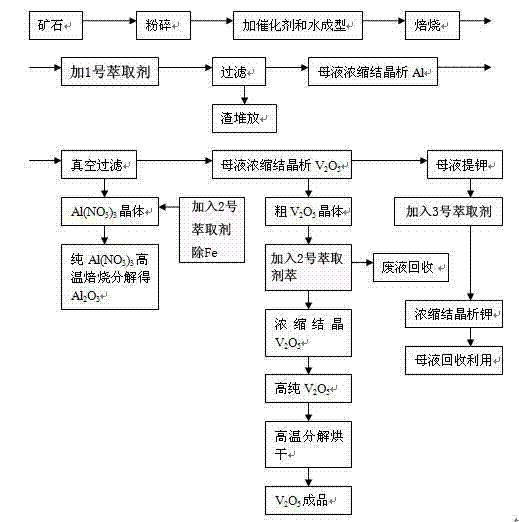

[0011] Now in conjunction with accompanying drawing, the process flow of the present invention will be further described.

[0012] 1000 kilograms of mineral powder process operation embodiment:

[0013] 1. Vanadium-containing rocks are used as raw materials, also known as black shale vanadium ore and stone coal, the color is black and yellow, and the main content of each component is V 2 o 5 : 0.82% (V: 0.46%), Al 2 o 3 : 17.08%, K: 1.98%, Fe: 4%, the raw material ore is ball milled into 60-80 mesh ore powder.

[0014] 2. Add sodium peroxide catalyst and water and stir to form a ball. Sodium peroxide and water (weight ratio 1:10) are prepared into an aqueous solution, and 2.5 kg (2.5 liters) of this aqueous solution is added per ton of ore.

[0015] 3. Roast in a flat kiln or a rotary furnace for 6 hours and keep warm at 600-720°C.

[0016] 4. Add No. 1 extractant, control the temperature at 80-110°C for 24 hours, and add 500 kg (500 liters).

[0017] 5. Filter with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com