SBR (Sequencing batch reactor) nitrosation quick start method

A rapid start-up, nitrosation technology, applied in the field of urban sewage treatment and resource utilization, to achieve the effect of high start-up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The test is based on simulated sewage water, and the specific water quality is as follows:

[0023] Influent water quality in start-up stage: NH 4 + -N=300-500mg / L, pH=7.70~8.20, temperature 25±1℃.

[0024] Influent water quality in stable operation stage with medium ammonia nitrogen: NH 4 + -N=150±15mg / L, pH=7.70~8.20, temperature 25±1℃.

[0025] Influent water quality in low ammonia nitrogen stable operation stage: NH 4 + -N=50±5mg / L, pH=7.70~8.20, temperature 25±1℃.

[0026] The specific treatment is as follows:

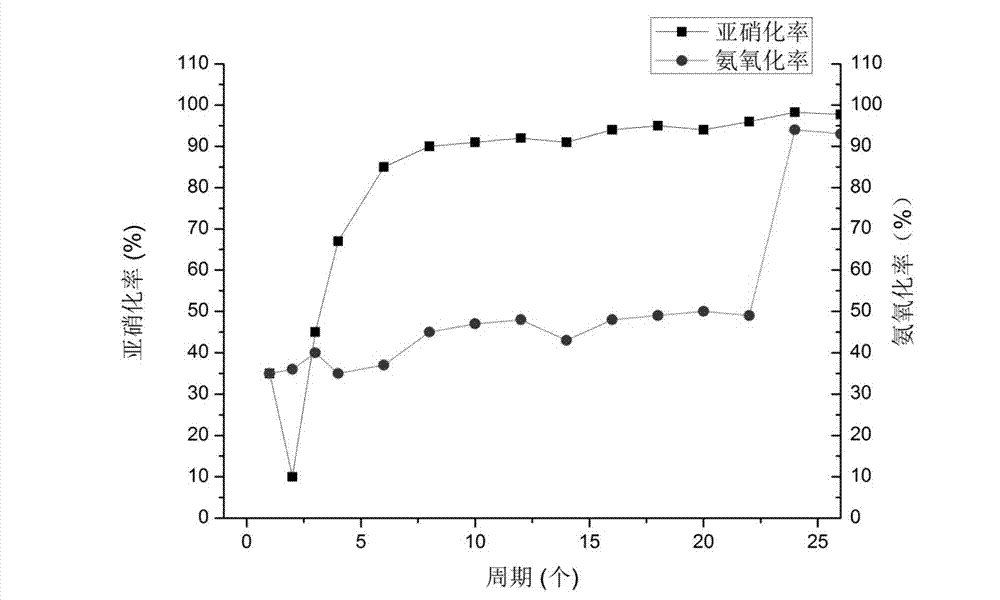

[0027] For the operation effect of nitrosative sludge during the start-up phase figure 1

[0028] Inoculate the returned nitrification sludge of the sewage treatment plant into the SBR reactor, control the concentration of ammonia nitrogen in the influent to 300-500mg / L, control the aeration rate to keep the dissolved oxygen at 0.2-0.5mg / L, and control the aeration time to make the ammonia oxidation rate Control it at 30%-50%, add sodium bicarbona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com