Biochemical method for treating synthetic leather wastewater containing dimethylformamide

A technology of dimethylformamide and synthetic leather, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as high production costs, achieve good removal effect, good Enrichment effect, effect of high removal potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

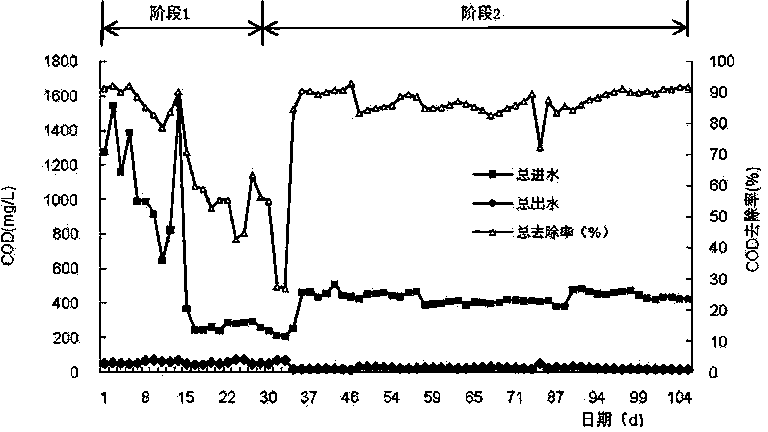

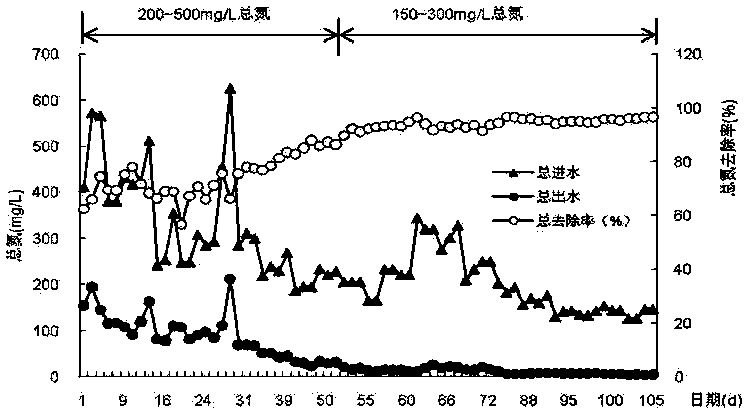

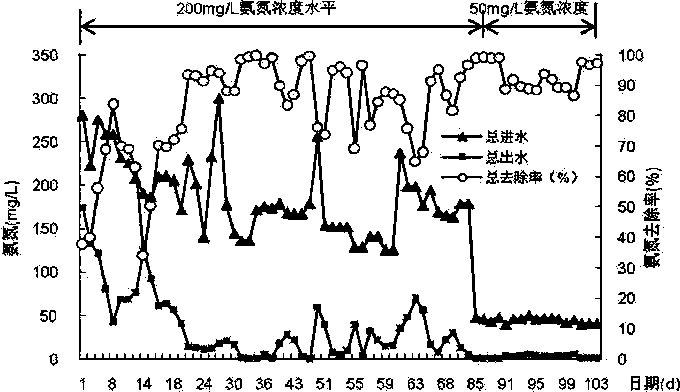

[0046] A synthetic leather tanning company, a large-scale enterprise with an annual output of 240,000 meters of PU leather, has a wastewater discharge of about 80,000 tons per year. The characteristics of its wastewater are quite representative in the domestic tanning industry. The original process is hydrolysis + contact oxidation + Coagulation and sedimentation, the effluent index is ammonia nitrogen 150-180mg / L, of which the ammonia nitrogen exceeds the standard seriously. But apply the biochemical method of the present invention, the pollutant index that comprises total nitrogen, ammonia nitrogen all can reach standard discharge, and concrete processing step is:

[0047]Step 1: Pass the synthetic leather wastewater containing dimethylformamide to be treated into a membrane bioreactor with an aerobic sludge-anaerobic filler structure, and control the influent water quality index of the synthetic leather wastewater to: CODcr is 166-1276mg / L, ammonia nitrogen is 169-311mg / L,...

Embodiment 2

[0054] A synthetic leather tanning company discharges about 50,000 tons of wastewater per year, and its ammonia nitrogen cannot meet the standard all year round, and the ammonia nitrogen exceeds the standard seriously. Applying the biochemical method of the present invention, the pollutant indicators including total nitrogen and ammonia nitrogen can reach the discharge standard, and the specific processing steps are:

[0055] Step 1: Pass the synthetic leather wastewater containing dimethylformamide to be treated into a membrane bioreactor with an aerobic sludge-anaerobic filler structure, and control the influent water quality index of the synthetic leather wastewater to: CODcr is 166-1276mg / L, ammonia nitrogen is 169-311mg / L, total nitrogen is 203-360mg / L all can, in the present embodiment, influent water quality index is as shown in table 2, the membrane bioreactor of this aerobic sludge-anaerobic packing structure Including aerobic zone 5 and anaerobic zone 6, the aerobic...

Embodiment 3

[0062] A synthetic leather tanning company discharges about 50,000 tons of wastewater per year, and its ammonia nitrogen cannot meet the standard all year round, and the ammonia nitrogen exceeds the standard seriously. Applying the biochemical method of the present invention, the pollutant indicators including total nitrogen and ammonia nitrogen can reach the discharge standard, and the specific processing steps are:

[0063] Step 1: Pass the synthetic leather wastewater containing dimethylformamide to be treated into a membrane bioreactor with an aerobic sludge-anaerobic filler structure, and control the influent water quality index of the synthetic leather wastewater to: CODcr is 166-1276mg / L, ammonia nitrogen is 169-311mg / L, total nitrogen is 203-360mg / L all can, in the present embodiment, influent water quality index is as shown in table 3, the membrane bioreactor of this aerobic sludge-anaerobic packing structure Including aerobic zone 5 and anaerobic zone 6, the aerobic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com