Method for processing oilfield wastewater and fixing CO2 (carbon dioxide) by using microalgae

A technology for oilfield sewage and CO2, applied in chemical instruments and methods, mining wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problems of immature large-scale breeding technology, difficulty in large-scale application, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

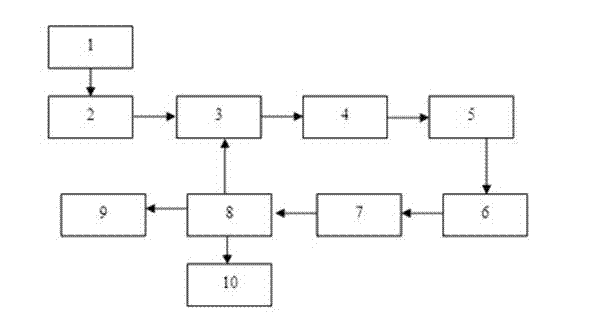

[0016] In order to further disclose the technical solution of the present invention, the following is a detailed description with embodiments in conjunction with the accompanying drawings of the specification:

[0017] The implementation process is as follows:

[0018] A method of using microalgae to treat oilfield sewage and fix CO 2 Firstly, the oilfield sewage is tested; to ensure that the crude oil contained in the oilfield sewage is less than 10 mg / L, the TOC in the sewage is less than 40 mg / L, and the COD is less than 100 mg / L. Then proceed as follows:

[0019] (1) Change CO 2 The gas is directly passed into the fresh oilfield sewage in the gas-water preliminary mixing tank 1, and the CO 2 Non-CO gas 2 The components chemically or physically react with some pollutants in the oilfield sewage, and the pollutants that affect the growth of microalgae are removed. After the gas and water are mixed, they enter the mixed water quality stabilization pool 2 for water quality stabilizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com