Viscosifier for drilling fluid and preparation method thereof

A technology of drilling fluid and viscosifier, which is applied in the direction of chemical instruments and methods, drilling compositions, etc. It can solve the problem that the high temperature resistance performance cannot meet the high temperature construction requirements, the viscosifying effect of the viscosifier decreases rapidly, and the viscosifier cannot To meet the construction requirements and other issues, to achieve a wide range of practical application prospects and economic benefits, good viscosity-increasing effect, and good viscosity-increasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

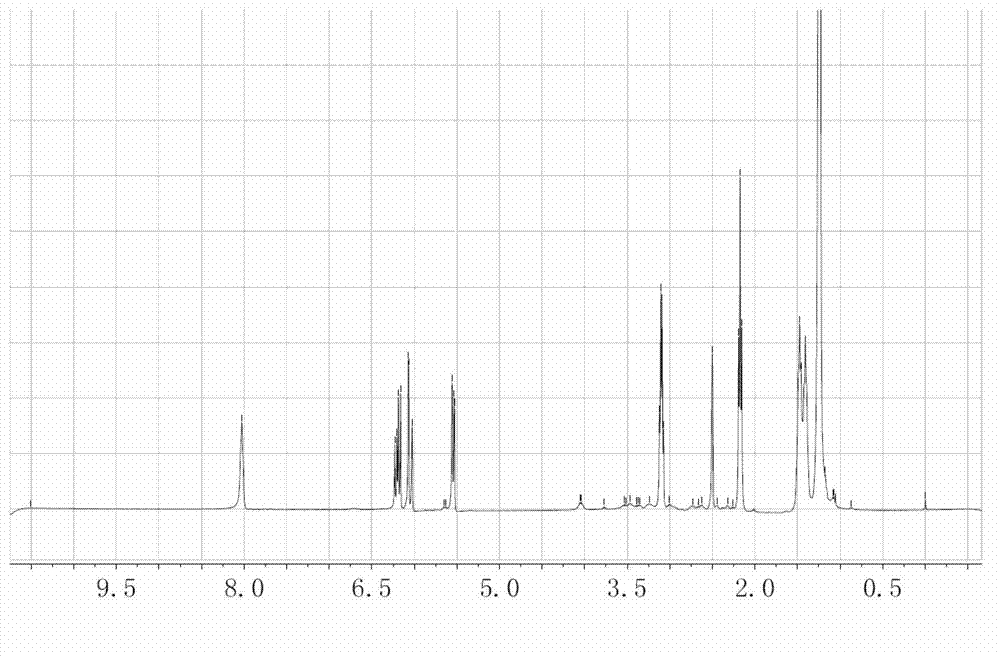

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of drilling fluid viscosifier, comprising:

[0028] A) Add a basic compound to the mixed solution to adjust the pH value to 6.0-8.0 to obtain a reaction solution; the mixed solution includes non-ionic water-soluble monomers, anionic water-soluble monomers, cationic hydrophobic monomers and deionized water; or include nonionic water-soluble monomers, cationic water-soluble monomers, anionic hydrophobic monomers, and deionized water;

[0029] B) mixing the reaction solution obtained in step A) with an initiator, and performing a polymerization reaction to obtain a drilling fluid viscosity enhancer;

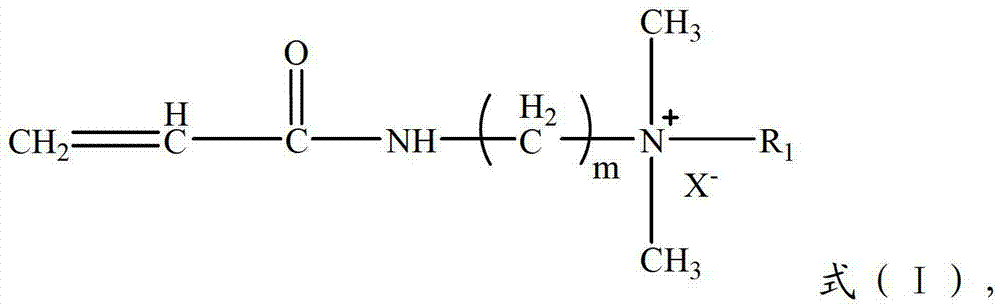

[0030] The cationic hydrophobic monomer has the structure shown in formula (I):

[0031]

[0032] Among them, R 1 from C 8 ~C 16 The alkyl group, m is 2 or 3; X is Cl, Br or I;

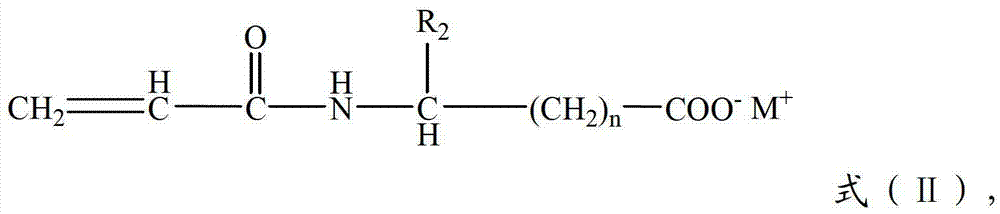

[0033] The anionic hydrophobic monomer has the structure shown in formula (II):

[0034]

[0035] where R 2 Choose from H or C 1 ~C ...

Embodiment 1

[0066] Add 8.8g of N,N-dimethylethylenediamine, 10mL of dichloromethane and 11g of sodium carbonate into the three-necked flask, stir, and put it in an ice-water bath; add 25mL of dichloromethane into the dropping funnel, and then pipette Add 10g of acryloyl chloride into the tube, mix well and drop into the three-necked flask, control the titration rate to 3-4 drops per minute, stir and react for 0.5 hours after the dropwise addition, and keep the temperature below 5°C during the whole dropping process. After the reaction was finished, the product was suction filtered to remove the solid, and the filtrate was washed twice with a saturated sodium carbonate solution and once with a saturated sodium chloride solution; Extract with methyl chloride, then separate the liquids, combine the lower clear liquid with the previous lower clear liquid, then dry with anhydrous magnesium sulfate, and let it stand overnight; filter the dried liquid to remove the magnesium sulfate solid, and th...

Embodiment 2

[0075] Add 10g of N,N-dimethyl-1,3-propanediamine, 11mL of dichloromethane and 11g of sodium carbonate into a three-necked flask, stir, and put it in an ice-water bath; add 18mL of dichloromethane into the dropping funnel, Then add 10g of acryloyl chloride with a pipette, mix well and drop it into a three-necked flask, control the titration rate to 3-4 drops per minute, stir and react for 0.5 hours after the dropwise addition, keep the temperature below 5°C during the whole dropping process . After the reaction was finished, the product was suction filtered to remove the solid, and the filtrate was washed twice with a saturated sodium carbonate solution and once with a saturated sodium chloride solution; Extract with methyl chloride, then separate the liquids, combine the lower clear liquid with the previous lower clear liquid, then dry with anhydrous magnesium sulfate, and let it stand overnight; filter the dried liquid to remove the magnesium sulfate solid, and then carry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com