Environment-friendly type water-saving agricultural mulching film and preparation method for same

An agricultural mulching film, an environmentally friendly technology, applied in plant protection covers, etc., can solve the problems of moisture conservation, heat preservation, water retention, fertilizer retention, short service life, etc., achieve good market application prospects, save resources, and protect the ecological environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

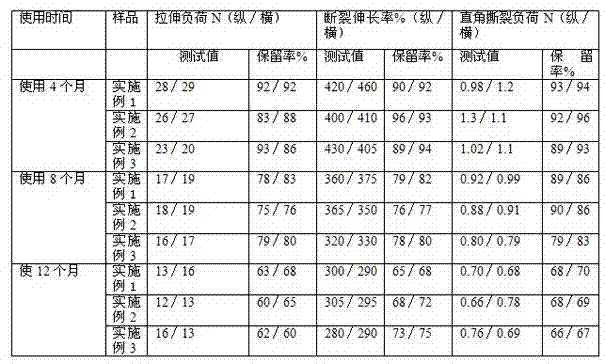

Examples

Embodiment 1

[0020] A. Preparation of water-retaining resin masterbatch, thermal insulation additives and weathering agent masterbatch

[0021] Add raw materials according to the following weight percentages to prepare water-retaining resin masterbatch: sodium polyacrylate 3%, dispersant stearic acid 1.5%, dispersant polyethylene wax 1.5%, sulfur 2%, linear low density polyethylene powder 72%, low Density polyethylene powder 15%, high-density polyethylene powder 5%;

[0022] Add raw materials according to the following weight percentages to prepare insulation aid masterbatch: 1% calcium carbonate, 1% synthetic silica, 3% talcum powder, 1.0% dispersant polyethylene wax, 74% linear low density polyethylene powder, low Density polyethylene powder 15%, high-density polyethylene powder 5%;

[0023] Add raw materials according to the following weight percentages to prepare weathering agent masterbatch: 1% antioxidant, 0.5% light stabilizer, 0.8% ultraviolet absorber, 1.5% dispersant polyethyle...

Embodiment 2

[0029] A. Preparation of water-retaining resin masterbatch, thermal insulation additives and weathering agent masterbatch

[0030] Add raw materials according to the following weight percentages to prepare water-retaining resin masterbatch: sodium polyacrylate 6%, dispersant stearic acid 3%, dispersant polyethylene wax 3%, sulfur 5%, linear low-density polyethylene powder 43%, low Density polyethylene powder 30%, high-density polyethylene powder 10%;

[0031] Add raw materials according to the following weight percentages to prepare insulation aid masterbatch: 3% calcium carbonate, 3% synthetic silica, 8% talcum powder, 3% dispersant polyethylene wax, 43% linear low density polyethylene powder, low Density polyethylene powder 30%, high-density polyethylene powder 10%;

[0032] Add raw materials according to the following weight percentages to prepare weathering agent masterbatch: antioxidant 2%, light stabilizer 1%, ultraviolet absorber 1.5%, dispersant polyethylene wax 3%, l...

Embodiment 3

[0038] A. Preparation of water-retaining resin masterbatch, thermal insulation additives and weathering agent masterbatch

[0039] Add raw materials according to the following weight percentages to prepare water-retaining resin masterbatch: sodium polyacrylate 3%, dispersant stearic acid 2%, dispersant polyethylene wax 2%, sulfur 3%, linear low-density polyethylene powder 60%, low Density polyethylene powder 22%, high-density polyethylene powder 8%;

[0040] Add raw materials according to the following weight percentages to prepare insulation aid masterbatch: calcium carbonate 1.5%, synthetic silica 1.5%, talc powder 5%, dispersant polyethylene wax 2%, linear low density polyethylene powder 60%, low Density polyethylene powder 22%, high-density polyethylene powder 8%;

[0041] Add raw materials according to the following weight percentages to prepare weathering agent masterbatch: antioxidant 1.5%, light stabilizer 0.8%, ultraviolet absorber 1.2%, dispersant polyethylene wax 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com