Amphoteric ionic ultra-high-temperature polysulfonate drilling fluid

A zwitterion, ultra-high temperature technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as difficulty in meeting drilling needs, improve high temperature water loss performance, increase adsorption strength, prevent high temperature coalescence and The effect of high temperature dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

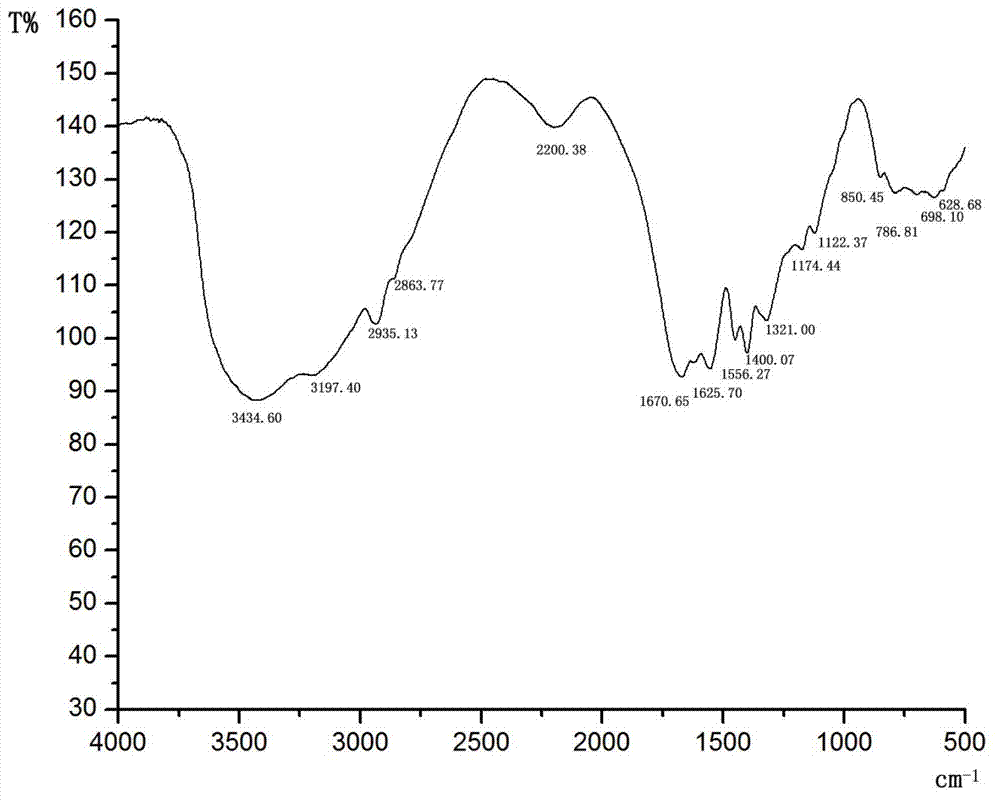

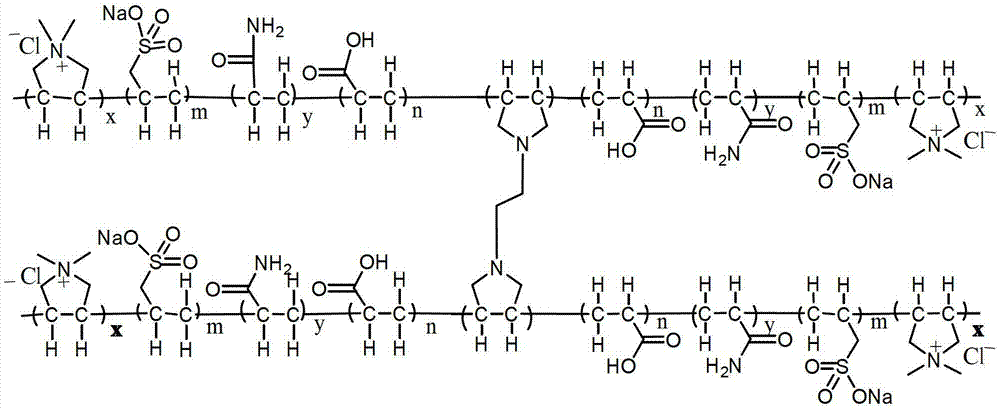

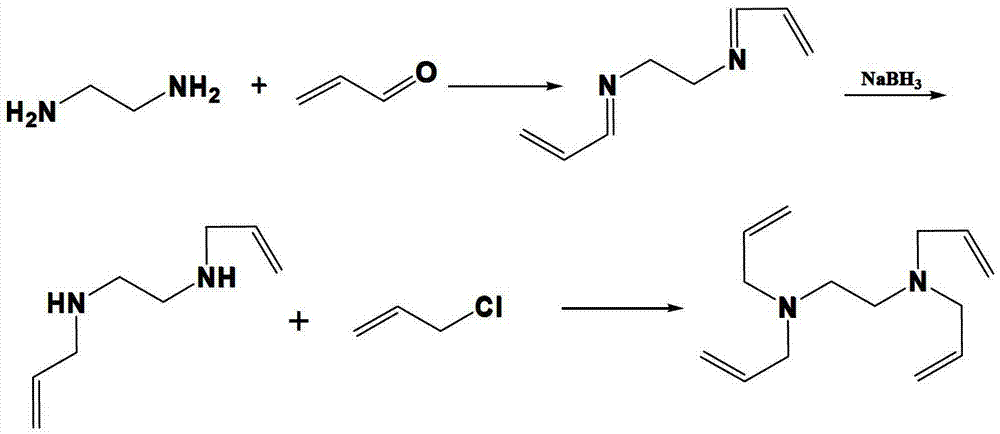

Image

Examples

preparation example Construction

[0047] 2. Preparation of zwitterionic polysulfonate ultra-high temperature drilling fluid

[0048] Preparation of bentonite base slurry: Measure 500ml of tap water, pour it into a 1000ml enamel tank, place it under the mixer and stir at a low speed, weigh 20g~30g of bentonite (4%~6%) and slowly add it into the water. After adding the bentonite, continue to stir at a low speed for 20 minutes, stop stirring, pour the bentonite slurry into a high-speed mixing cup, stir with a high-speed mixer for 2 minutes (11000 rpm), and then let it stand for hydration for 24 hours.

example 1

[0051]

example 2

[0053]

[0054] 3. Performance test of zwitterionic polysulfonate ultra-high temperature drilling fluid

[0055] (1) Performance comparison of zwitterionic polysulfonated ultra-high temperature drilling fluid before and after thermal rolling

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com