Nanocrystalline quantum dot with core-shell structure and preparation method of nanocrystalline quantum dot

A technology of nanocrystals and quantum dots, which is applied in the field of nanocrystal quantum dots and its preparation, can solve problems such as poor stability, reduced efficiency, and stability impact, and achieve the effects of excellent luminescent materials, improved fluorescence efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

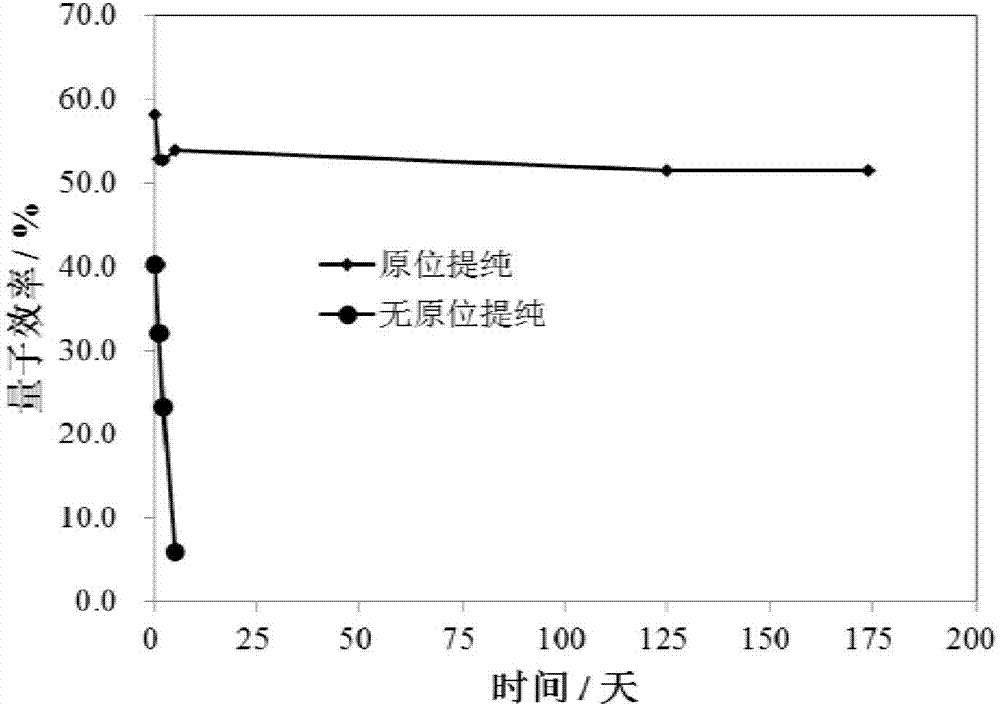

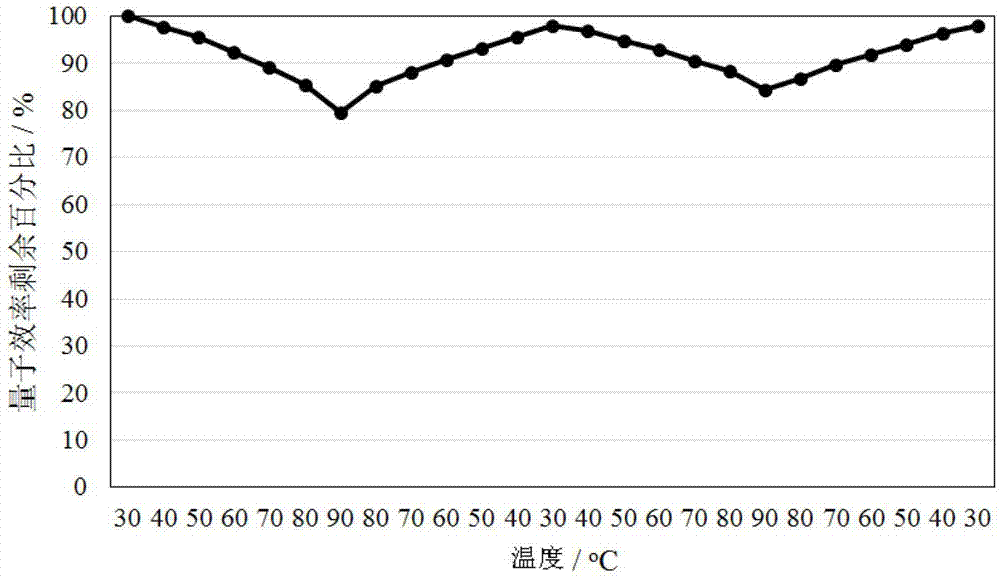

[0024] The invention provides a method for preparing nanocrystalline quantum dots with a core-shell structure, comprising the following steps: preparing a nanocrystalline core; Nanocrystalline quantum dots; wherein, the step of in-situ purification of the nanocrystalline nucleus is also included before the step of in-situ coating the surface of the nanocrystalline nucleus with zinc sulfide, and / or after the step of in-situ coating the surface of the nanocrystalline nucleus with zinc sulfide A step of in-situ purification of nanocrystalline quantum dots is included.

[0025] During the in-situ coating process of zinc sulfide on the surface of the nanocrystalline core, the in-situ purification of the uncoated zinc sulfide nanocrystalline core or the coated nanocrystalline quantum dots or the uncoated zinc sulfide nanocrystalline After the crystal nucleus is purified, the nanocrystalline quantum dots coated with zinc sulfide are purified again, which improves the fluorescence eff...

Embodiment approach

[0027] According to a typical embodiment of the present invention, the step of in-situ purifying the nanocrystalline core or nanocrystalline quantum dots includes: adding the nanocrystalline quantum dots that have not been coated with zinc sulfide to the solution of nanocrystalline cores that have not been coated with zinc sulfide. Add an organic purifying agent to the mixture, stir it with magnetic force, let it stand for stratification, and separate to obtain surface-purified nanocrystalline cores or nanocrystalline quantum dots. Organic purifiers refer to organic solvents that can remove copper ions, indium ions and other acid ligands, amine ligands, etc. The species of epitaxial growth facilitates the continued growth of ZnS on the surface of quantum dots. The in-situ purification step solves the problem that the epitaxial growth of the zinc sulfide layer is hindered by factors such as the migration of copper ions or indium ions or surface impurities on the surface of the ...

Embodiment 1

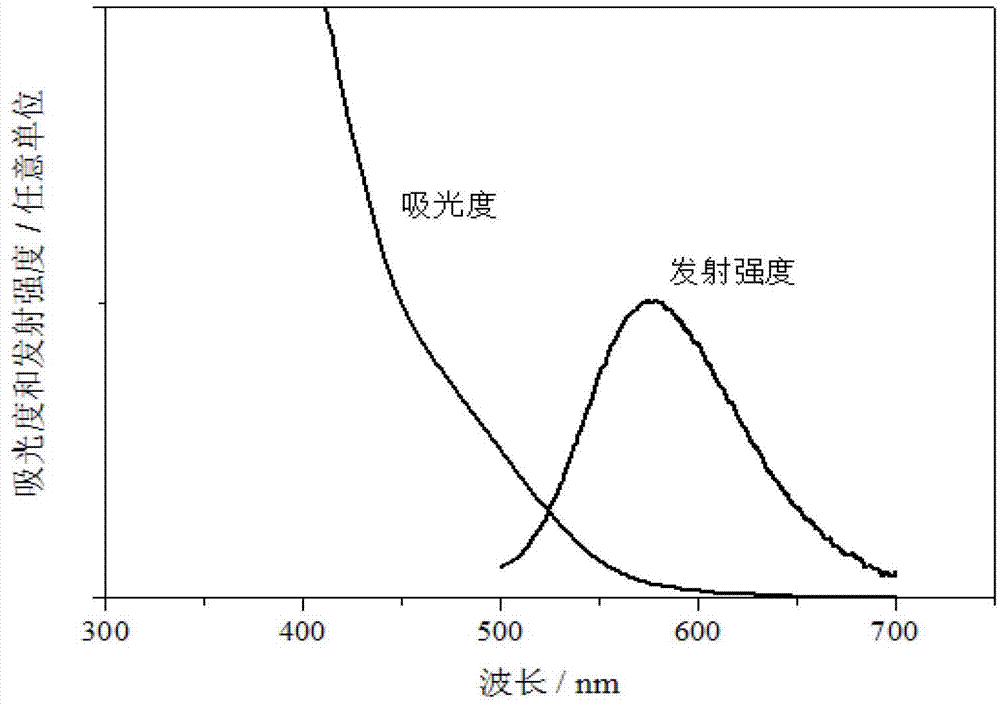

[0040] Preparation of I-III-VI / II-VI nanocrystalline quantum dots Cu-Zn-In-S / ZnS:

[0041] First, take 0.15mmol of zinc acetate, 0.1mmol of indium acetate, 0.05mmol of cuprous acetate, 0.6mmol of oleic acid, 2mmol of dodecanethiol and 100mmol of octadecene, mix and heat to 50°C to dissolve completely. Raise the temperature to 100°C, inject 1 mL of octadecene solution (0.1 mol / L) dissolved with sulfur powder, and react for 60 minutes to generate a Cu-Zn-In-S structure nanocrystal nucleus solution.

[0042] Add 1 mL of zinc stearate octadecene solution (0.1 mol / L) and 1 mL of octadecene solution (0.1 mol / L) dissolved with sulfur powder into the above-mentioned nanocrystal nucleus solution with Cu-Zn-In-S structure. L), that is, a precursor containing sulfur ions, heated to 180° C. for 30 minutes, and coated with a ZnS shell on the surface of the nanocrystalline core. Then add methanol for in-situ purification. After the layers are separated, extract the methanol solution in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com