Method for preparing nitrogen-doped activated carbon by utilizing PET (polyethylene terephthalate) waste material

A nitrogen-doped, activated carbon technology, used in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as environmental pollution and resource waste, and achieve reasonable pore size distribution, high specific surface area, and good electrochemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

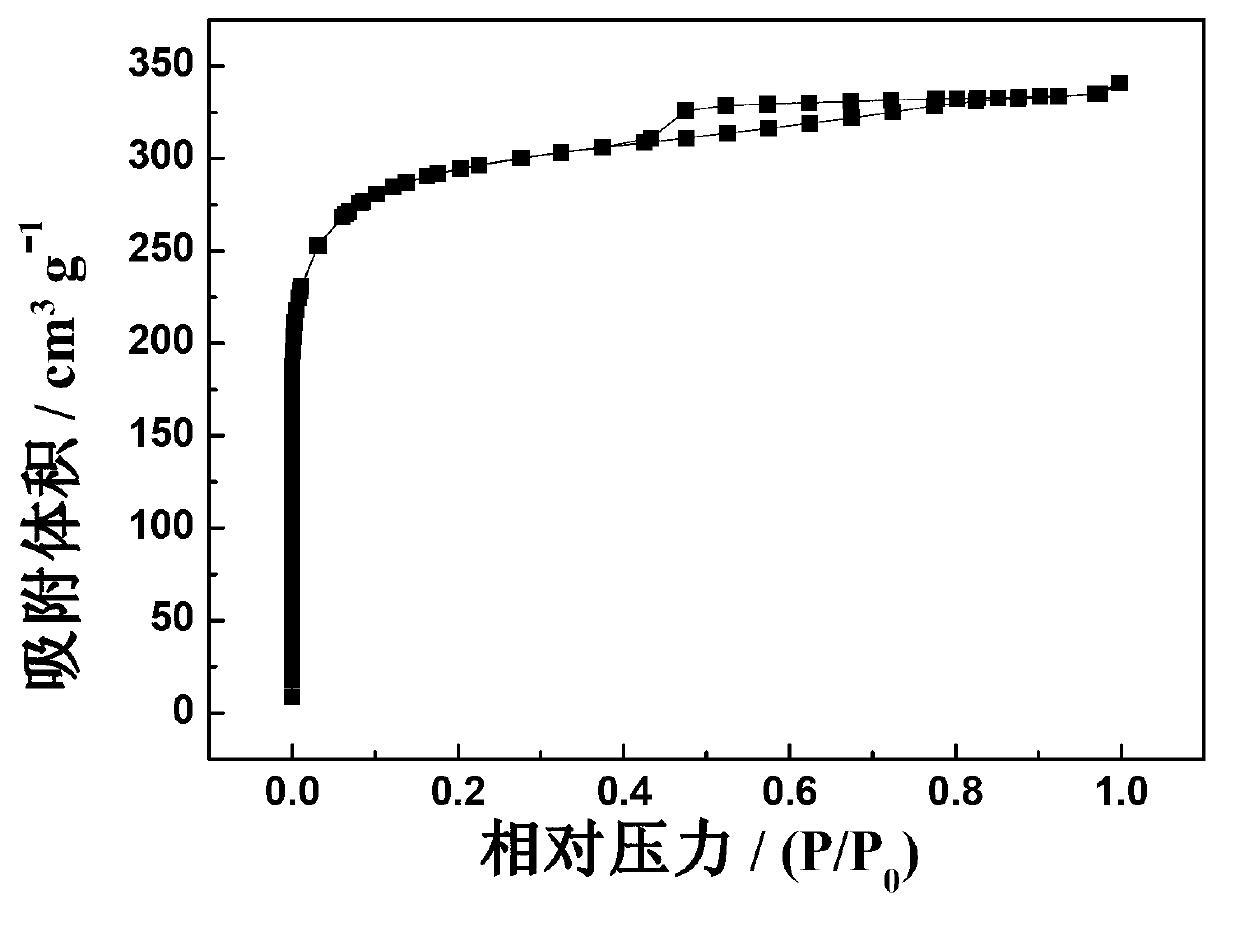

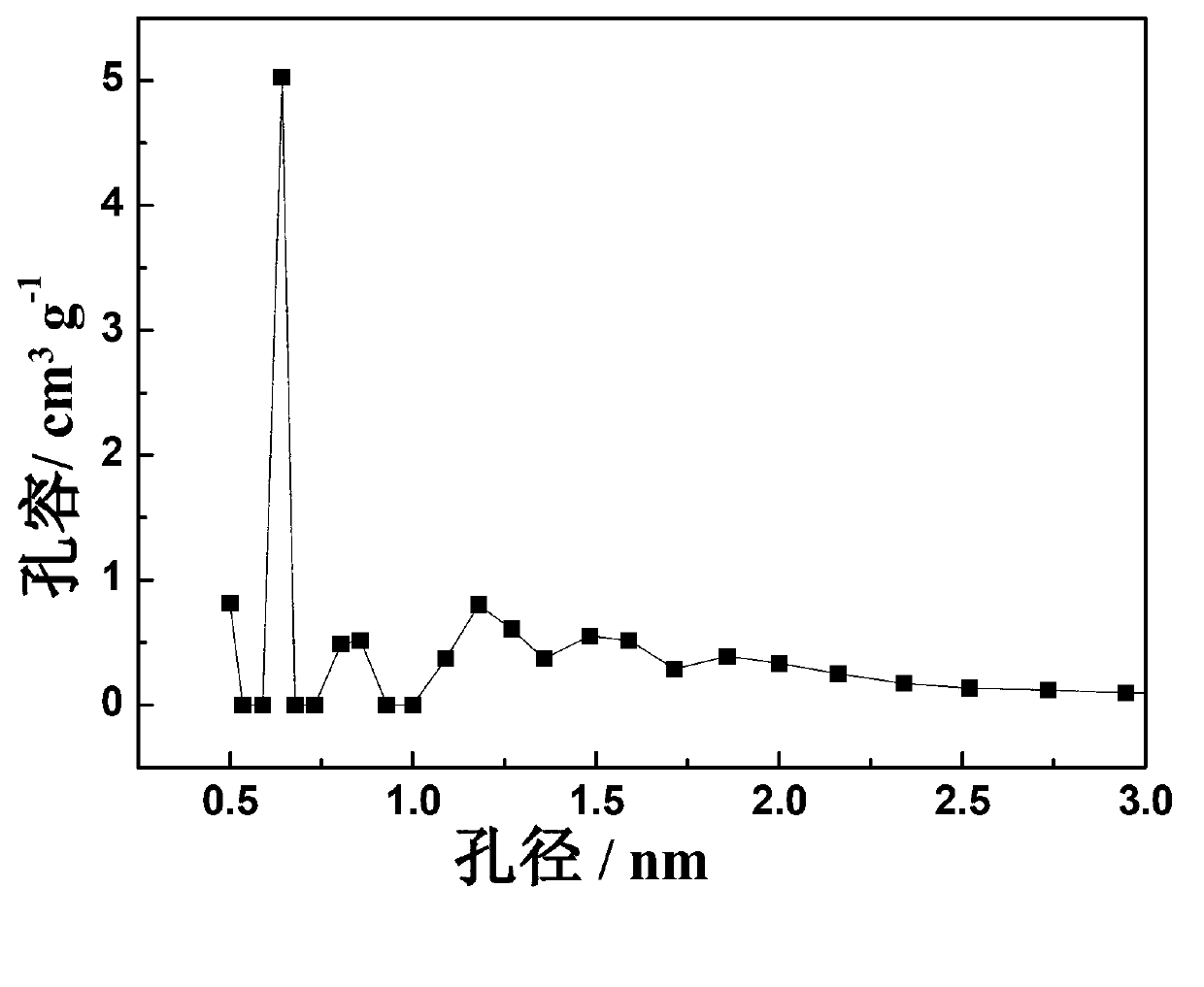

Embodiment 1

[0022] PET waste was pre-oxidized at 400 °C in an air atmosphere for 8 h, and the obtained pre-oxidized material was mixed with melamine at a mass ratio of 1:3. The resulting mixture was heated to 500 °C at a rate of 5 °C / min under an argon atmosphere of 9 L / h at room temperature. ℃ carbonization for 3 h. Then, the carbonized product was heated to an activation temperature of 900°C under the conditions of an argon flow rate of 9 L / h and a heating rate of 5°C / min, and switched to 9 L / h of CO 2 Constant temperature in activated gas for 4 h. After activation, switch to argon with a flow rate of 9 L / h and cool to room temperature to obtain nitrogen-doped activated carbon. The main properties of the activated carbon are shown in Table 1.

Embodiment 2

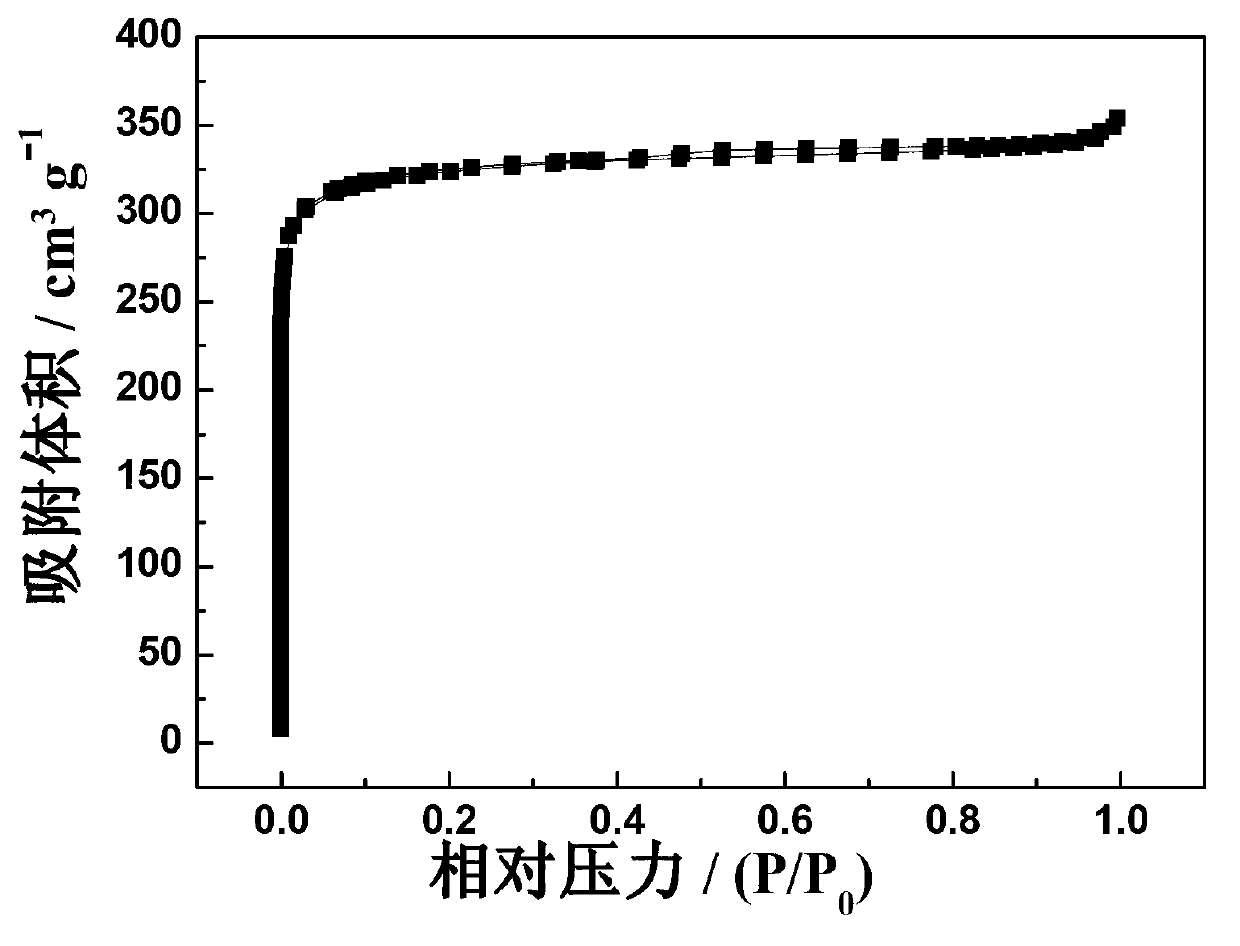

[0024] PET waste was pre-oxidized at 250 °C in an air atmosphere for 48 h, and the obtained pre-oxidized material was mixed with ammonium phosphate at a mass ratio of 1:8. The resulting mixture was heated at a rate of 2 °C / min to 400 °C under a nitrogen atmosphere of 3 L / h at room temperature. ℃ carbonization for 5 h. Then, the carbonized product was heated to an activation temperature of 800°C under the conditions of a nitrogen flow rate of 3 L / h and a heating rate of 2°C / min, and switched to 3 L / h of H 2 O activated gas at constant temperature for 6 h. After activation, switch to nitrogen with a flow rate of 3 L / h and cool to room temperature to obtain nitrogen-doped activated carbon. The main properties of the activated carbon are shown in Table 1.

Embodiment 3

[0026] The PET waste was pre-oxidized in an air atmosphere at 300 °C for 24 h, and the obtained pre-oxidized material was mixed with dicyandiamide at a mass ratio of 1:1. The resulting mixture was carbonized at room temperature at a rate of 5 °C / min to 550 °C for 2 h in a helium atmosphere of 6 L / h. Then, the carbonized product was heated to an activation temperature of 400°C under the conditions of a helium flow rate of 6 L / h and a heating rate of 5°C / min, and switched to 6 L / h of O 2 Constant temperature in activated gas for 1 h. After activation, switch to helium with a flow rate of 6 L / h and cool to room temperature to obtain nitrogen-doped activated carbon. The main properties of the activated carbon are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com