Toluene methylation method for increasing yield of o-xylene and p-xylene

A technology of toluene methylation and p-xylene, which is applied in the field of toluene methylation to increase the production of o-xylene and p-xylene, can solve the problems of high price of organosilicon modifiers, cumbersome process steps, expensive solvents, etc., and achieve change Acid center distribution, inhibition of isomerization reaction, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0019] Take 30 grams of mordenite with different degrees of sodium exchange (silicon-aluminum ratio of 15) and binders in a certain proportion and mix them evenly before molding. After constant temperature roasting for a certain period of time, catalysts A-D are obtained. See Table 1 for details.

[0020] Table 1 catalyst preparation

[0021] Example

Embodiment 5-8

[0023] Take 30 grams of mordenite with different sodium exchange degrees and silicon-aluminum ratios and alumina binders in proportion and mix them uniformly before molding. After calcination at 500°C for 6 hours, catalysts E-H are obtained. See Table 2 for details.

[0024] Table 2 catalyst preparation

[0025] Example

Embodiment 9~17

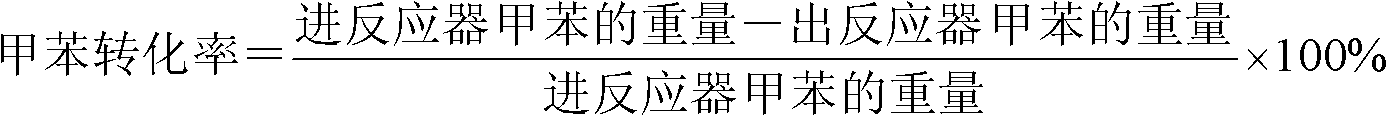

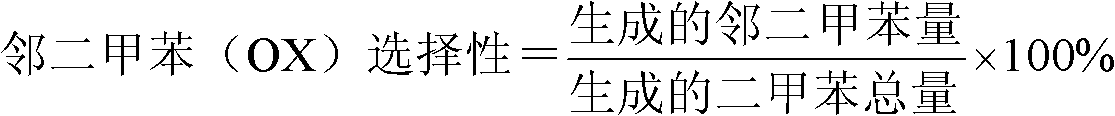

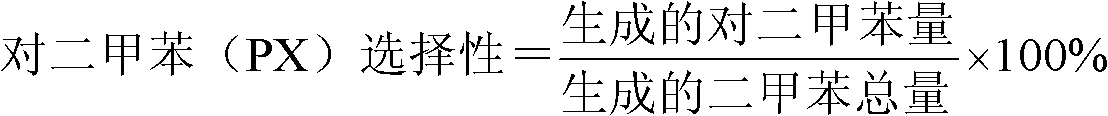

[0029] The performance of catalysts A-H and comparative catalyst X in catalyzing the alkylation reaction of toluene with methanol was investigated on a fixed-bed reaction evaluation device. The molar ratio of raw material toluene to methanol was 2:1, the catalyst loading was 5g, the reaction temperature was 400°C, and the reaction pressure was 1.0MPa, feed space velocity (WHSV) 6.0h -1 , Hydrocarbon molar ratio 1.0. After reacting for 2 hours, the product composition was analyzed, and the results are listed in Table 3.

[0030]

[0031]

[0032]

[0033]

[0034] Table 3 Different catalysts catalyze the performance of toluene methanol alkylation reaction

[0035] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com