Moisture-proof coating method used for traditional Chinese medicine salvia miltiorrhiza extract powder or particles

A technology of extract powder and traditional Chinese medicine, which is used in pharmaceutical formulations, powder delivery, medical preparations containing active ingredients, etc., to achieve high stability, avoid contact, and good moisture-proof effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Salvia miltiorrhiza dry extract powder 500g, 6% starch slurry 10g, glyceryl palmitostearate (PrecirolATO5) 50g

[0019] (1) Processing of Danshen dry extract powder before coating: take 2000g of Danshen decoction slices, add four times the amount of water to extract and decoct four times, decoct for 1.5h each time, filter, combine the decoctions, and concentrate to a relative Density is 1.30 (90 ℃) clear ointment, dry under reduced pressure, pulverize, pass through 60 mesh sieves to obtain 1600g of traditional Chinese medicine salvia miltiorrhiza root extract powder, set aside;

[0020] (2) Place 500 g of the dry powder of Danshen extract prepared in step 1 in a Glatt top-spray fluidized bed coating machine to control the atomization pressure to 1.5 Pa, the inlet air temperature to 50-55°C, and the material temperature to 45-47°C. ℃, granulate 10g of starch slurry with 6% (injected at a rate of 10.8g / min), and stop granulating after forming free small particles; install...

Embodiment 2

[0025] Salvia miltiorrhiza dry extract powder 500g, 6% starch slurry starch 10g, COMPARITOL888ATO 50g

[0026] The salvia salviae extract dry powder 500g that embodiment 1 step (1) makes is placed in the fluidized bed coating machine of Glatt top spray type, and the control atomization pressure is 1.5 Pa, and inlet air temperature is 50-55 ℃, and material temperature is At 45-47°C, granulate with 10g of 6% starch slurry (injected at a rate of 10.8g / min), and stop granulating after forming free small particles; install a double-layer nozzle system as a spray gun device, set The air inlet temperature is 48-55°C, the temperature of the coating material reaches 68-73°C, and the coating is applied at a spray rate of 6.5g / min. When the coating liquid is sprayed, stop heating and blow 30°C cold air to 33 ℃, take out, that is.

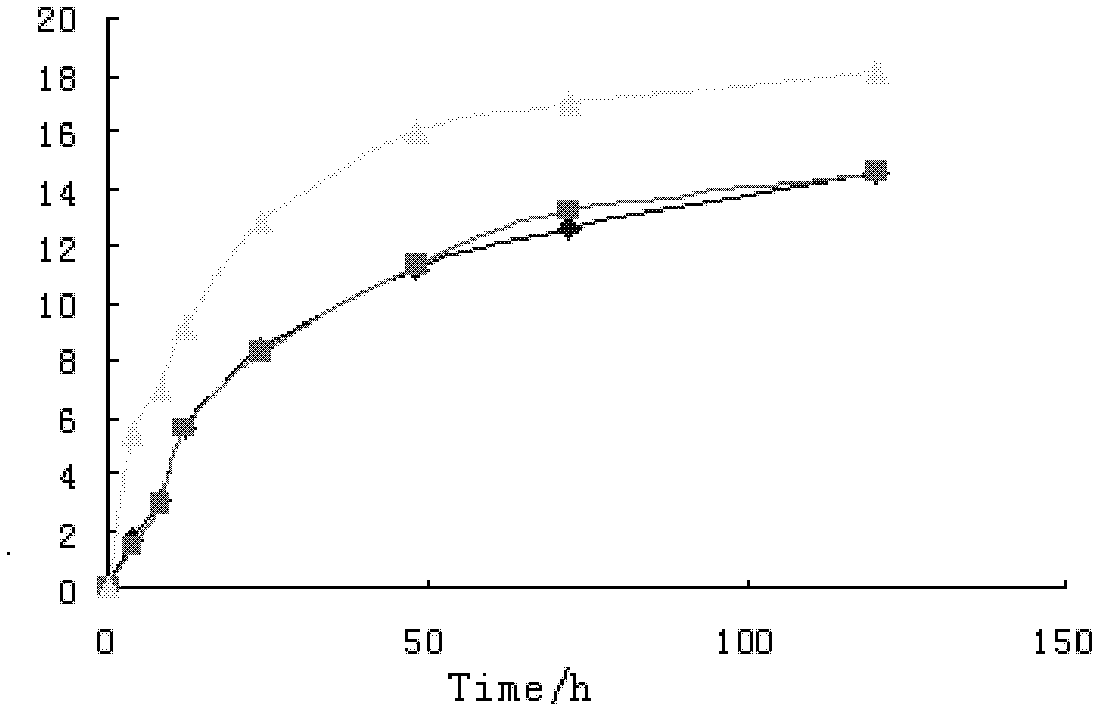

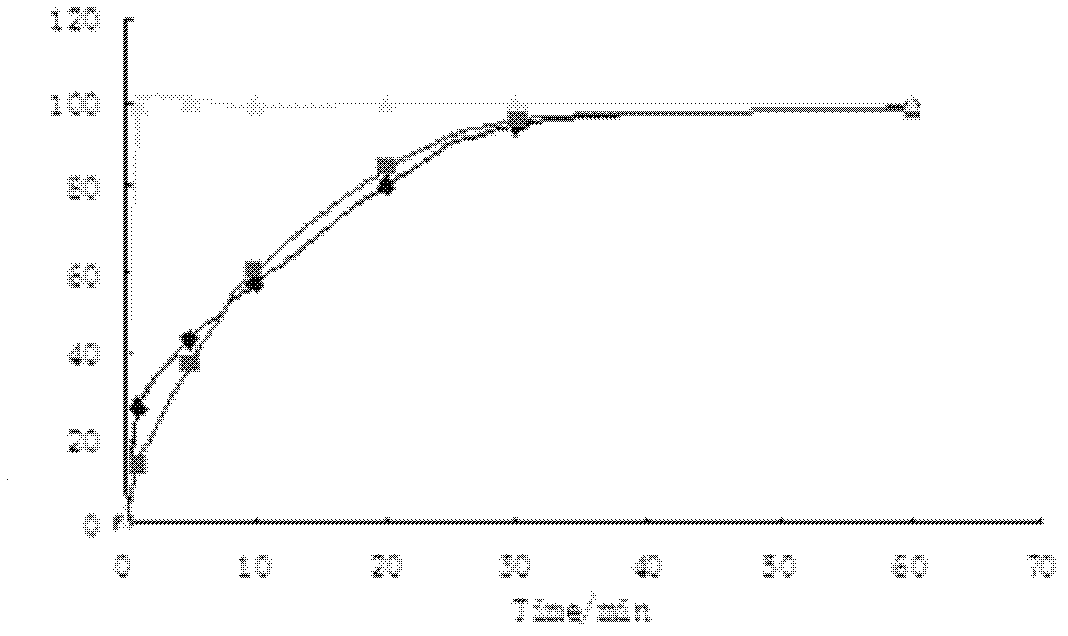

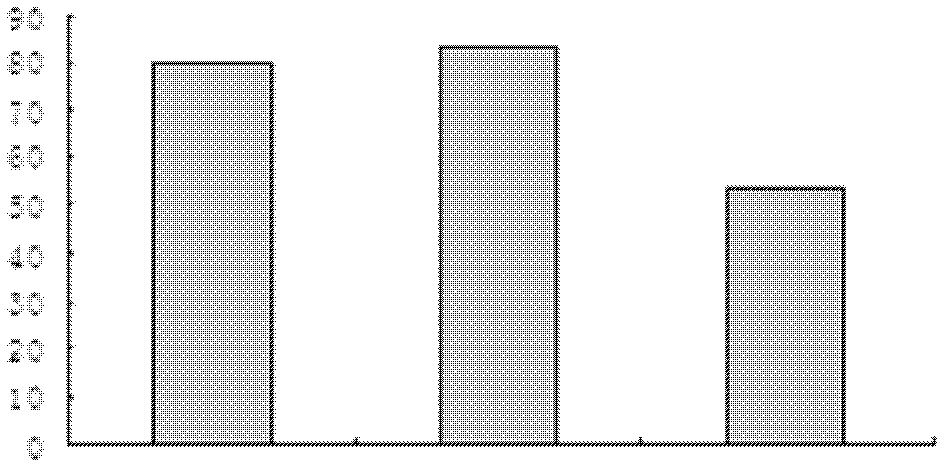

[0027] The results of hygroscopicity study showed that the equilibrium moisture absorption rate of the coated Danshen extract powder was 80.28% of that of th...

Embodiment 3

[0031] Danshen Granules 100g Glycerin Palmitostearate (PrecirolATO5) 5g

[0032] (1) Processing of traditional Chinese medicine Danshen dry extract powder before coating: take 1000g of Danshen decoction pieces, add 90% ethanol (6000ml) to reflux for 1.5h, filter, recover ethanol from the filtrate to a thick paste (relative density is 1.20-1.25); The dregs were decocted with water for 1 hour, filtered, the filtrate was combined with the above thick paste, concentrated under reduced pressure (concentrated by rotary evaporation at 80°C) and dried (vacuum dried at 80°C) to obtain 540 g of extract powder, crushed, and passed through 60 mesh screen. Take 250g of the prepared extract powder, select dextrin in a ratio of 1:1, use dilute ethanol as a wetting agent to make granules, pass through a 14-mesh sieve, dry at 50°C, pass through a 10-mesh sieve, and granulate to obtain Salvia granules 450g.

[0033] Put 100g of Salvia miltiorrhiza granules in a top-spray fluidized bed coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com