Lateral powder feeding nozzle device applied to laser cladding

A lateral powder feeding and laser cladding technology, applied in laser welding equipment, coatings, metal material coating processes, etc., can solve the problems of nozzle powder blockage, reduced laser cladding efficiency, and lack of protective gas makeup function. , to achieve the effect of reducing sticky powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

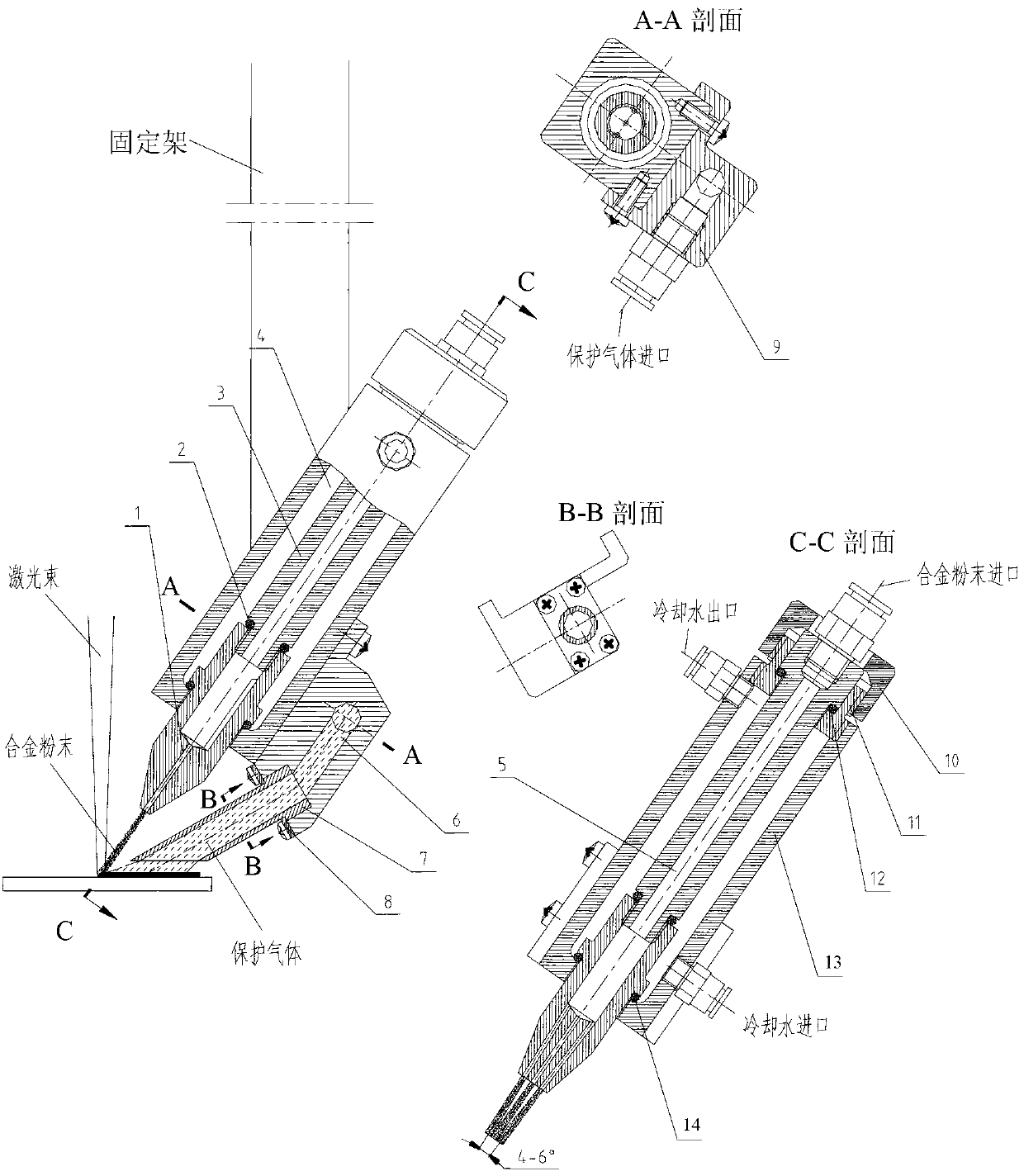

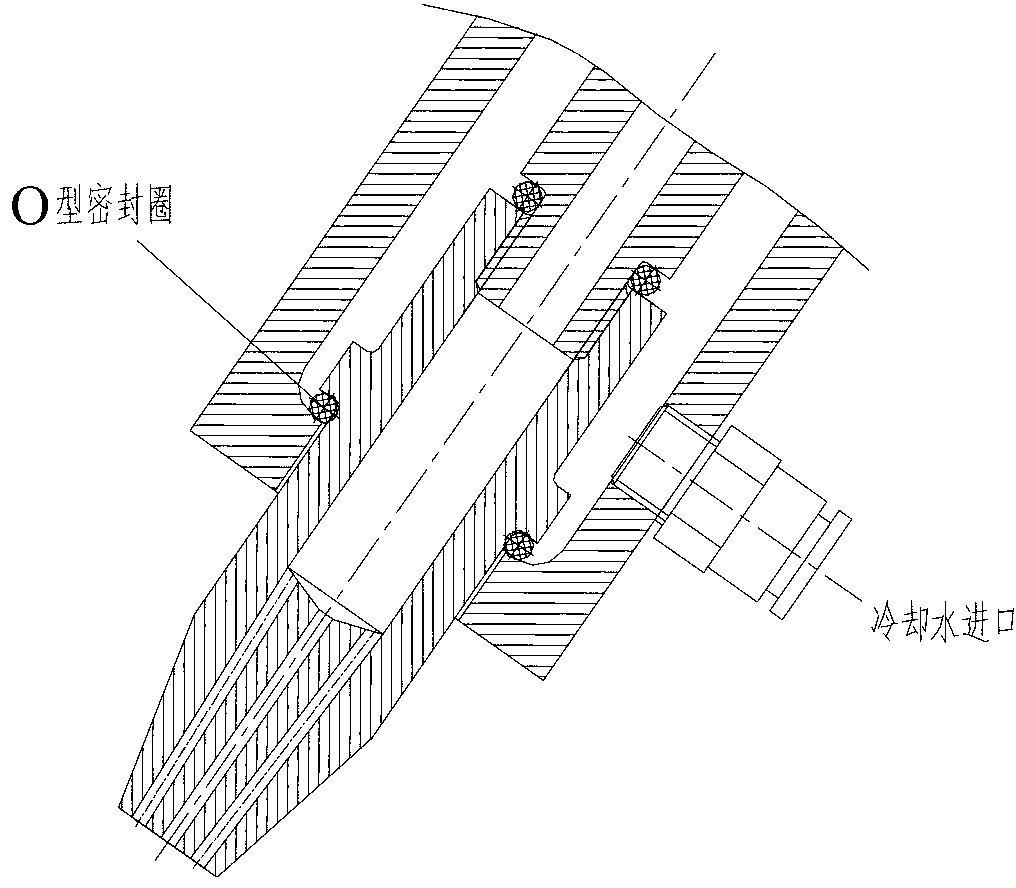

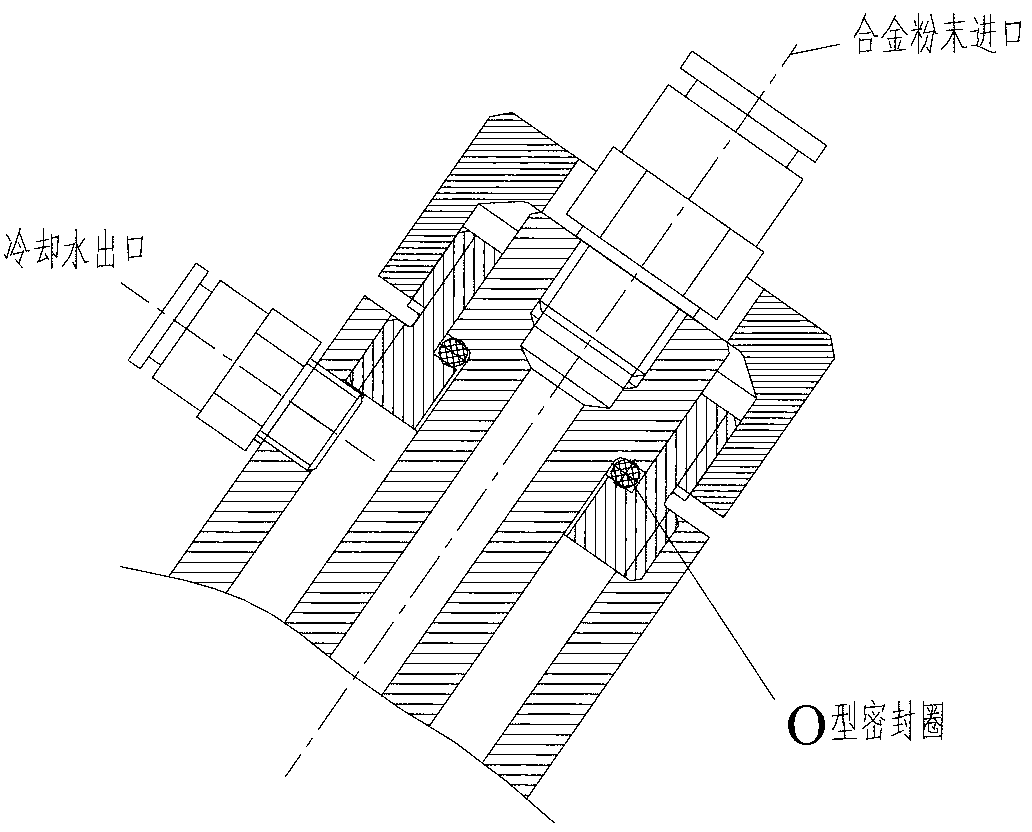

[0021] figure 1 It shows a lateral powder feeding nozzle for laser cladding in a preferred embodiment of the present invention, including a powder outlet nozzle 1, a sealing ring 2, a powder feeding pipe 3, a cooling water jacket 4, a powder feeding channel 5, and a protective air channel 6. Protective gas copper pipe 7, pressure plate 8, air passage structure 9, gland 10, intermediate connecting sleeve 11, cooling water sleeve body 13, characterized in that powder feeding channel 5 includes powder outlet nozzle 1, powder feeding pipe 3. The alloy powder inlet is installed on the powder feeding pipe 3, the powder outlet nozzle 1 is threadedly connected with the powder feeding pipe 3, the cooling water jacket is placed outside the powder feeding nozzle and the powder feeding pipe, and the powder outlet nozzle 1 is immersed in cooling water In the cooling water of the jacket, the powder nozzle 1 can fully dissipate heat and can work for a long time. An O-shaped sealing ring 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com