Multi-light-source interference exposure device

An interference exposure, multi-light source technology, applied in the field of lithography, can solve the problems of limited exposure light intensity, low laser power, low production efficiency, etc., and achieve the effects of high resolution, improved production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

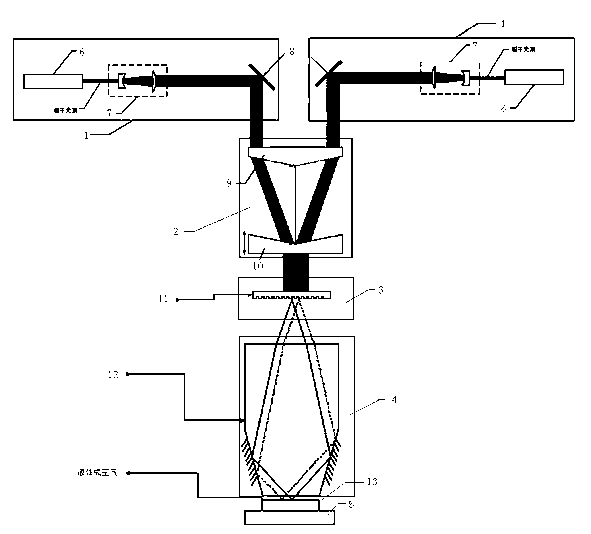

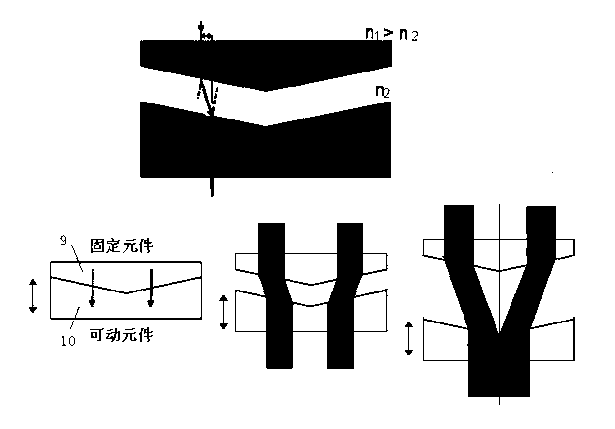

[0034] Embodiment 1 of the present invention such as figure 1 As shown, the multi-light source interference exposure device includes two illumination units 1 , a light combining unit 2 , a diffraction unit 3 , an interference unit 4 and a stage 5 and five major parts. The lighting unit 1 includes a light source 6 , a beam expander 7 and a reflector 8 , which converts the light emitted by two sets of laser light sources into parallel light spots, and enters the light combining unit 2 through two sets of reflectors 8 . The light combining unit 2 is composed of two wedge prisms 9 and 10 . The diffraction unit 3 is a phase grating 11 , the interference unit 4 is a converging prism 12 , and the stage 5 unit includes a wafer stage and a silicon wafer 13 .

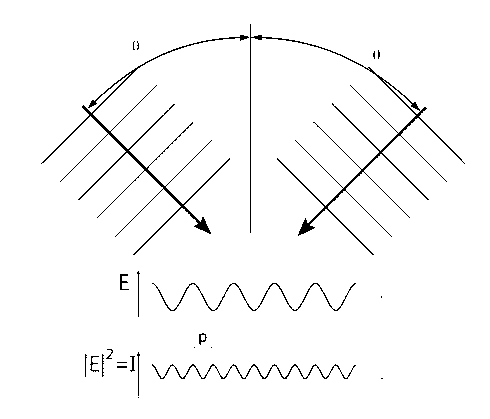

[0035] The working process of the device is as follows: by 2 light sources 6, usually lasers, each sends a beam of coherent beams (in the present invention, interference will not occur between 2 beams of coherent beams sent by 2...

Embodiment 2

[0046] The second embodiment of the present invention is as Figure 6 As shown, it also includes five parts: an illumination unit 1 , an optical unit 2 , a diffraction unit 3 , an interference unit 4 and a stage 5 .

[0047] In this embodiment, the light-merging unit and the light-merging principle are the same as those in Embodiment 1.

[0048] It differs from Example 1 in the use of different interference elements. The interfering element in the present embodiment is a rhombic prism 14, and its light path diagram is as follows Figure 7 As shown, therefore the interference exposure forms the fringe period (pitch):

[0049] (4)

[0050] And +1, -1 order diffraction angle θ is:

[0051] (5)

[0052] Here Pitch1 is the period of the diffraction grating. Assuming that the direction of the diffracted light in the prism is parallel to the optical axis, the wedge angle of the prism It is defined by the following formu...

Embodiment 3

[0059] The third embodiment of the present invention is as Figure 8 As shown, it includes four parts: an illumination unit 1 , a light combining unit 2 , an interference unit 4 and a stage 5 .

[0060] In this embodiment, the light-merging unit and the light-merging principle are the same as those in Embodiment 1.

[0061] It differs from Embodiment 1 in that there is no diffraction unit, and the interference elements are also different. The interfering element in the present embodiment is a trapezoidal prism 15, and its light path figure is as follows Figure 9 shown. The key point of splicing and interference here is that half of the spot of each beam of parallel light is incident on one surface of the trapezoidal prism 15, and the other half is incident on the surface at another angle, so that two parts of the beam emitted by the same laser interfere through the trapezoidal prism 15, The interference light produced by each of the two beams of light is then focused on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com