Hybrid electrode, its preparation method and solar cell using the hybrid electrode

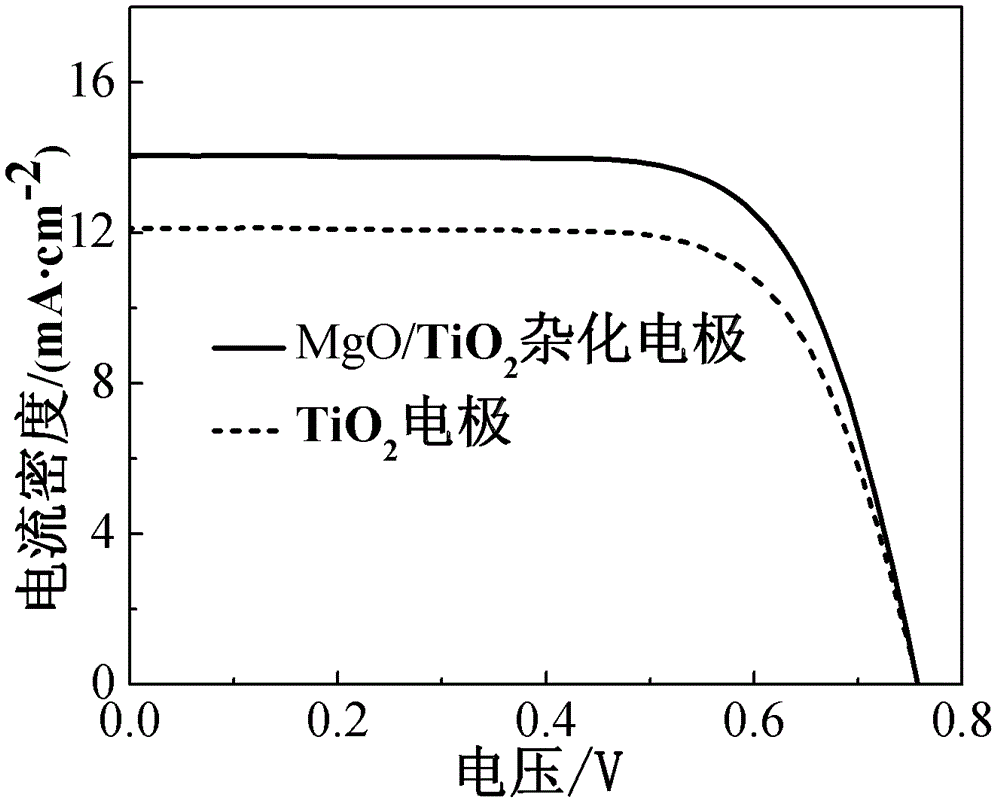

A hybrid and electrode technology, applied in the field of solar cells, can solve the problems of low energy conversion efficiency, low electron mobility, and large resistance of photovoltaic cells, and achieve the effects of improving photoelectric conversion efficiency, improving separation efficiency, and avoiding hole recombination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

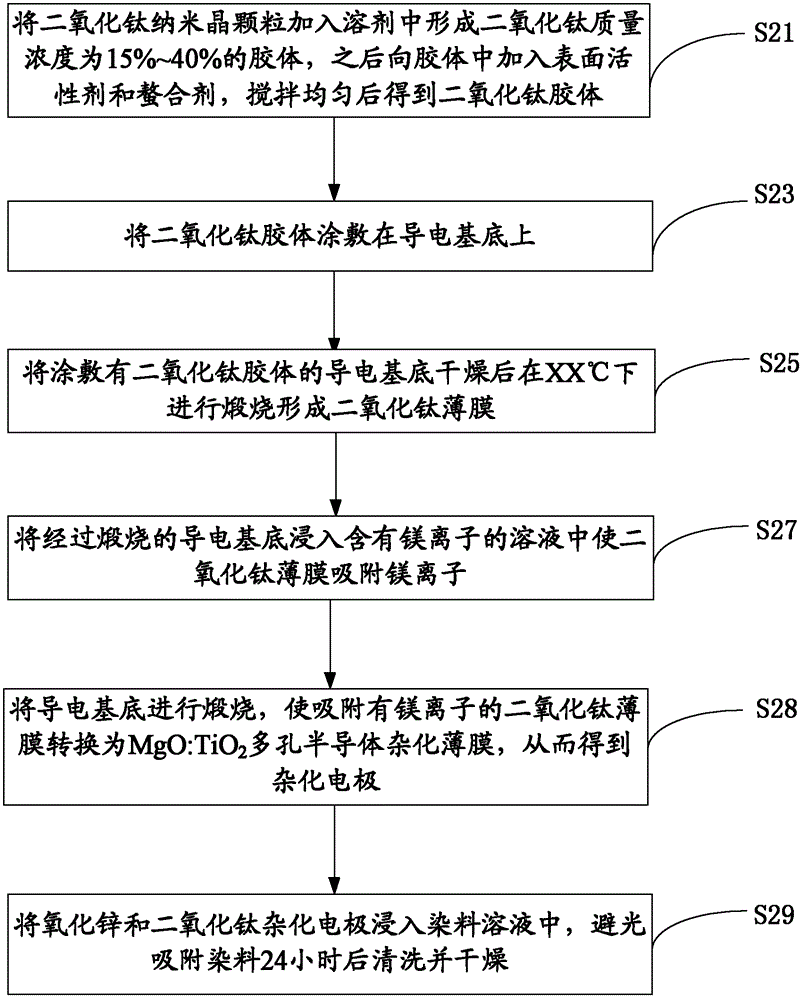

[0025] see figure 1 , the preparation method of the hybrid electrode of an embodiment, comprises the following steps:

[0026] Step S21, adding titanium dioxide nanocrystalline particles into a solvent to form a colloid with a mass concentration of titanium dioxide of 15% to 40%, then adding a surfactant and a chelating agent to the colloid, and stirring evenly to obtain a titanium dioxide colloid.

[0027] In this embodiment, the particle size of the titanium dioxide particles is 20 nm to 100 nm. The solvent is at least one selected from distilled water, ethanol, n-butanol or isopropanol.

[0028] In this embodiment, the surfactant is OP emulsifier or polyethylene glycol p-isooctyl phenyl ether (triton). The mass concentration of the surfactant in the titanium dioxide colloid is 1% to 5%.

[0029] In this embodiment, the chelating agent is acetylacetone. The mass concentration of the chelating agent in the titanium dioxide colloid is 1% to 10%.

[0030] In this embodimen...

Embodiment 1

[0048] Nano TiO 2 Added to distilled water, configured as TiO 2 The mass concentration is 25% TiO 2 For the colloid, add triton and acetylacetone in sequence so that the mass concentration of triton is 3%, and the mass concentration of acetylacetone is 6%, and grind for 30 minutes.

[0049] After the conductive substrate is cleaned and pretreated, the above-prepared colloid is scraped on the surface of the conductive film by scraping. After drying, the temperature is raised to 450°C at a rate of 20°C / min, and then This temperature was kept for 30 minutes, and then naturally cooled to 80°C.

[0050] Dissolve magnesium acetate in distilled water to make Mg 2+ The concentration is 0.05mol / L, and then the above prepared TiO 2 The porous film is immersed in 500ml of magnesium acetate solution, soaked for 3h, and then taken out and dried. Once again, the temperature was raised to 450°C at a rate of 20°C / min, and then kept at this temperature for 30 minutes, and then naturally c...

Embodiment 2

[0053] Nano TiO 2 Added to distilled water, configured as TiO 2 The mass concentration is 15% TiO 2 For the colloid, add triton and acetylacetone in turn, so that the mass concentration of triton is 1%, and the mass concentration of acetylacetone is 1%, and it is scraped by the method of Example 1, and calcined at high temperature.

[0054] Dissolve magnesium sulfate in distilled water to make Mg 2+ The concentration is 0.01mol / L, and then the above-prepared TiO 2 The porous film is immersed in 500ml of magnesium sulfate solution, soaked for 10h, then taken out, dried and calcined at high temperature to obtain MgO:TiO 2 The thickness of the porous semiconductor hybrid film is 12 μm.

[0055] Referring to Example 1, a dye-sensitized solar cell was assembled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com