Binder composition for electrode

A composition and adhesive technology, applied in electrode manufacturing, battery electrodes, electrode current collector coating, etc., can solve problems such as adverse environmental impact, peeling of electrode active material layer, easy self-discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0159] The preparation of the electrode slurry is preferably performed under reduced pressure, thereby preventing generation of air bubbles in the obtained electrode active material layer.

[0160] The above-mentioned slurry for electrodes contains the binder composition for electrodes of the present invention, so it can form an electrode active material layer with high adhesion between electrode active materials and between electrode active materials and current collectors, and can provide An electrochemical device with excellent electrochemical stability in a high-temperature environment.

[0161]

[0162] Electrodes of the present invention include:

[0163] current collector,

[0164] An electrode active material layer formed through the steps of applying the above-described electrode slurry on the surface of the current collector and drying it.

[0165] After drying of the coating film, it is preferable to perform press processing.

[0166] [collector]

[0167] As t...

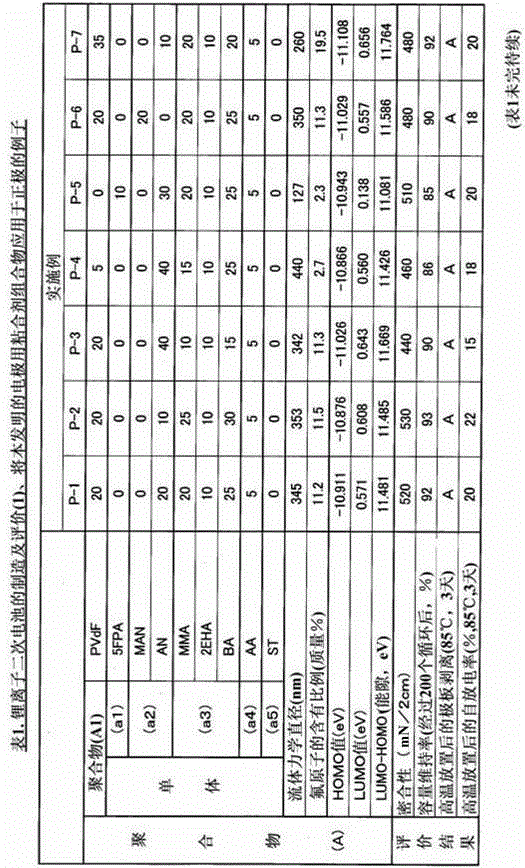

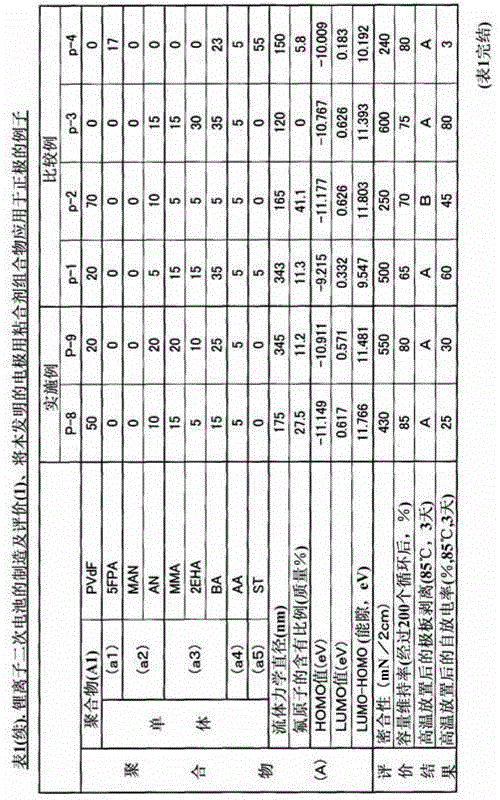

Embodiment

[0202] Hereinafter, the present invention will be described more specifically by way of examples and comparative examples, but the present invention is not limited to these examples and comparative examples.

[0203] Below, when "parts" and "%" are simply described, unless otherwise specified, they are the mass standards, respectively.

[0204] Measurement methods and evaluation methods of various characteristic values common to all Examples and Comparative Examples are as follows.

[0205]

[0206] (1) Hydrodynamic diameter

[0207] Each electrode binder composition was diluted about 1000 times with water as a measurement sample, and as a measurement device, a He Ne laser (λ=632.8nm) with an output power of 22mW was used as a light source made by ALV GmbH. The measurement was performed with a modified dynamic light scattering measuring device "ALV5000", and the measured number average particle diameter was used as the hydrodynamic diameter.

[0208] (2) Content ratio of...

Synthetic example 1

[0219] After fully nitrogen-substituting the inside of an autoclave with an internal volume of about 6 liters equipped with an electromagnetic stirrer, 2.5 liters of deoxygenated pure water and 25 g of ammonium perfluorodecanoate as an emulsifier were added to the above-mentioned autoclave. While stirring, the temperature was raised to 60°C. Next, supply vinylidene fluoride (VDF) gas into the autoclave until the inner pressure of the autoclave reaches 20 kg / cm 2 g. Then, using nitrogen as a carrier gas, 25 g of a Flon 113 solution containing 20% of diisopropyl peroxydicarbonate as a polymerization initiator was pressurized to initiate polymerization. During the polymerization process, VDF gas was gradually supplied to the above-mentioned autoclave to maintain the internal pressure at 20kg / cm 2 g. Here, since the polymerization rate slows down as the polymerization proceeds, 3 hours after the initiation of the polymerization, nitrogen gas was used as a carrier gas, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydrodynamic diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com