Black fungus dietary therapy health maintenance food and preparation method thereof

The technology of black fungus and diet therapy is applied in the field of black fungus diet and health care diet and its preparation, which can solve the problems of low bioavailability, high energy consumption and high cost, and achieve high bioavailability, low oil yield and rapid onset of effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

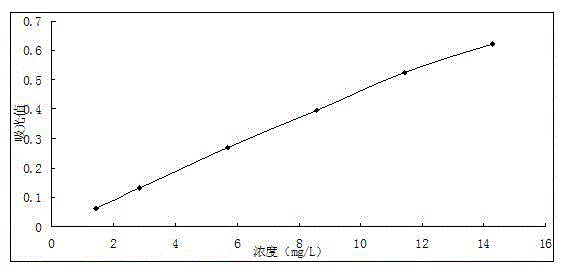

Image

Examples

Embodiment 1

[0035] Recipe: black fungus superfine powder 40kg, red dates (pitted) 14kg, wolfberry 14kg, purple sweet potato powder 14kg, dried ginger 12kg, xylitol 6kg.

[0036] Preparation Process:

[0037] (1) Soak the black fungus for 15 minutes, wash, drain, and steam in a steamer for 1.0 hour. After taking it out, vacuum-dry it at a drying temperature of 70°C and a vacuum degree of -0.08~-0.09Mpa until the moisture content is ≤ 3%, then add it to the superfine pulverizer, and grind it to 800-1000 mesh at a low temperature of 40°C;

[0038] (2) Red jujube pitted, pitted red jujube and goji berry are rinsed, then vacuum-dried at a drying temperature of 60°C and a vacuum degree of -0.08~-0.09Mpa until the moisture content is ≤5%, then mixed with purple sweet potato powder and crushed To 60-80 mesh;

[0039] (3) Dried ginger was sliced, crushed, and passed through a 14-mesh sieve to obtain dried ginger powder, and then the dried ginger powder was extracted with supercritical carbon dio...

Embodiment 2

[0045] Recipe: black fungus superfine powder 60kg, red dates (pitted) 8kg, wolfberry 8kg, purple sweet potato powder 8kg, dried ginger 8kg, xylitol 8kg.

[0046] Preparation Process:

[0047] (1) Soak black fungus for 30 minutes, wash, drain, and steam in a steamer for 0.5 hours. After taking it out, vacuum dry it at a drying temperature of 80°C and a vacuum degree of -0.08~-0.09Mpa until the moisture content is ≤ 3%, then add it to the ultrafine pulverizer, and grind it to 800-1000 mesh at a low temperature of 20°C;

[0048] (2) Red dates are pitted, pitted red dates and wolfberry are rinsed, then vacuum-dried at a drying temperature of 70°C and a vacuum degree of -0.08~-0.09Mpa until the moisture content is ≤5%, then mixed with purple sweet potato powder and crushed To 60-80 mesh;

[0049] (3) Dried ginger was sliced, crushed, and passed through a 14-mesh sieve to obtain dried ginger powder, and then the dried ginger powder was extracted with supercritical carbon dioxide a...

Embodiment 3

[0055] Recipe: black fungus superfine powder 50kg, red dates (pitted) 10kg, wolfberry 10kg, purple sweet potato powder 10kg, dried ginger 10kg, xylitol 10kg.

[0056] Preparation Process:

[0057] (1) Soak black fungus for 20 minutes, wash, drain, and steam in a steamer for 0.8 hours. After taking it out, vacuum dry it at a drying temperature of 75°C and a vacuum degree of -0.08~-0.09Mpa until the moisture content is ≤ 3%, then add it to the ultrafine pulverizer, and grind it to 800-1000 mesh at a low temperature of 10°C;

[0058] (2) Red jujube pitted, pitted red jujube and goji berry are rinsed, then vacuum-dried at a drying temperature of 65°C and a vacuum degree of -0.08~-0.09Mpa until the moisture content is ≤5%, then mixed with purple sweet potato powder and crushed To 60-80 mesh;

[0059] (3) Dried ginger was sliced, crushed, and passed through a 14-mesh sieve to obtain dried ginger powder, and then the dried ginger powder was extracted with supercritical carbon dioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area mean particle size | aaaaa | aaaaa |

| Surface area mean particle size | aaaaa | aaaaa |

| Surface area mean particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com