Calcitriol ointment and preparation method thereof

A technology for calcitriol and ointment, applied in ointment delivery, bone diseases, pharmaceutical formulations, etc., can solve problems such as low solubility of common organic solvents, monotonous dosage forms, and inability to exist stably for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 calcitriol ointment

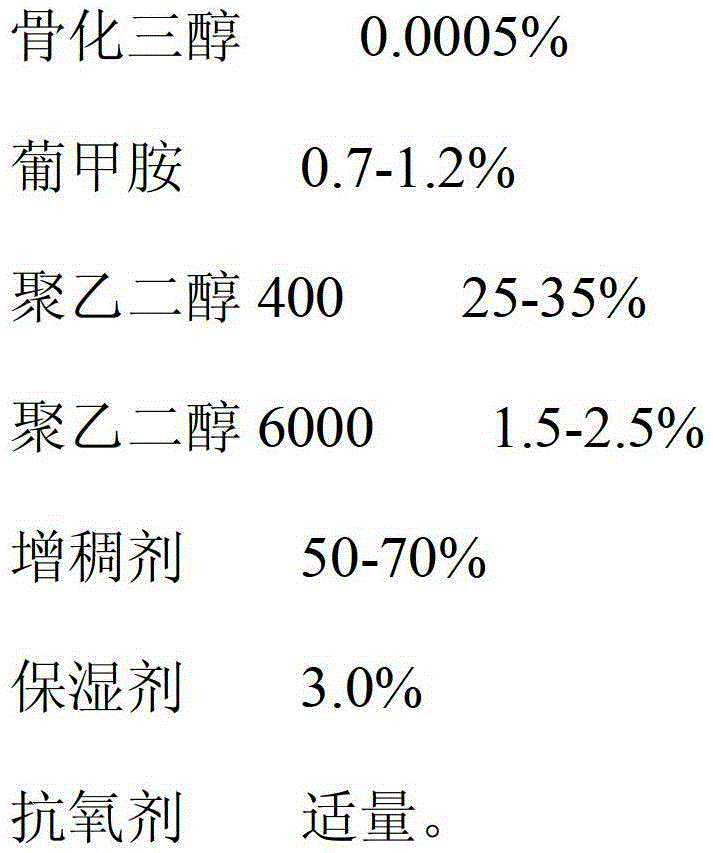

[0023] The prescription is:

[0024]

[0025]

[0026] The preparation method is:

[0027] 1) Mix the prescribed amount of xanthan gum, propylene glycol and di-tert-butyl-p-cresol, heat and stir at 60°C to dissolve, and obtain the base material;

[0028] 2) Pass the prescribed amount of calcitriol, meglumine, polyethylene glycol 400 and polyethylene glycol 6000 through a 80-mesh sieve, mix well, add the obtained mixture to the above base material at 60°C, and stir After 15 minutes until uniform, the temperature was lowered to 20°C to obtain the finished product.

Embodiment 2

[0029] Embodiment 2 calcitriol ointment

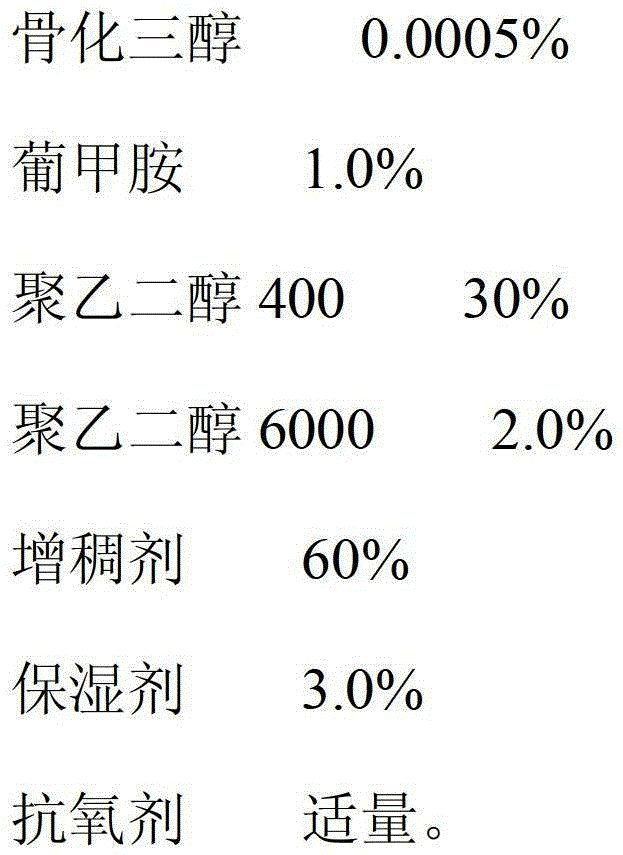

[0030] The prescription is:

[0031]

[0032] The preparation method is:

[0033] 1) Mix the prescribed amount of guar gum, glycerin and tert-butyl hydroxyanisole, heat and stir at 80°C to dissolve to obtain the base material;

[0034] 2) Pass the prescribed amount of calcitriol, meglumine, polyethylene glycol 400 and polyethylene glycol 6000 through a 120-mesh sieve, mix well, add the obtained mixture to the above base material at 80°C, and stir After 45 minutes until uniform, the temperature was lowered to 40°C to obtain the finished product.

Embodiment 3

[0035] Embodiment 3 calcitriol ointment

[0036] The prescription is:

[0037]

[0038] The preparation method is:

[0039] 1) Mix the prescribed amount of locust bean gum, sorbitol and sodium sorbate, heat and stir at 70°C to dissolve to obtain the base material;

[0040] 2) Pass the prescribed amount of calcitriol, meglumine, polyethylene glycol 400 and polyethylene glycol 6000 through a 100-mesh sieve, mix well, add the obtained mixture to the above base material at 70°C, and stir After 30 minutes until uniform, the temperature is lowered to 20-40°C to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com