Cerebroprotein hydrolysate and lyophilized powder thereof for injection

A technology of cerebroprotein hydrolyzate and freeze-dried powder injection, which is applied in the field of medicine, can solve the problems of affecting the drug safety of patients, restricting popularization and application, and poor homogeneity, so as to achieve excellent therapeutic effects, reduce production costs, and increase yields. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

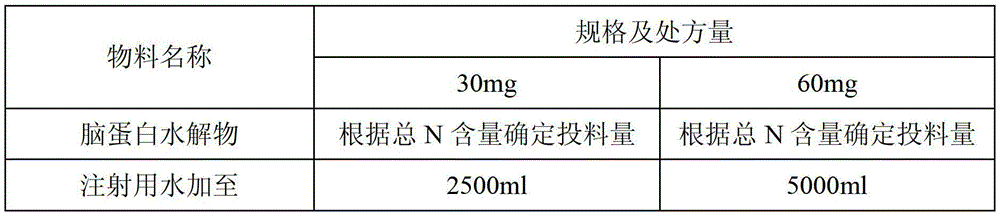

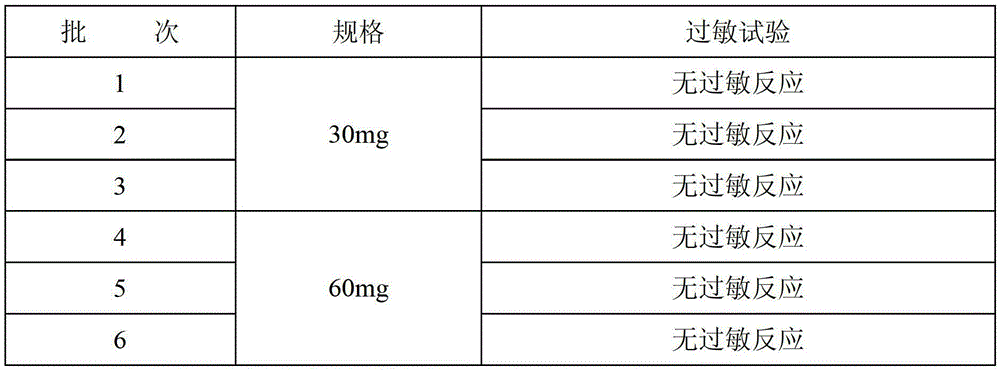

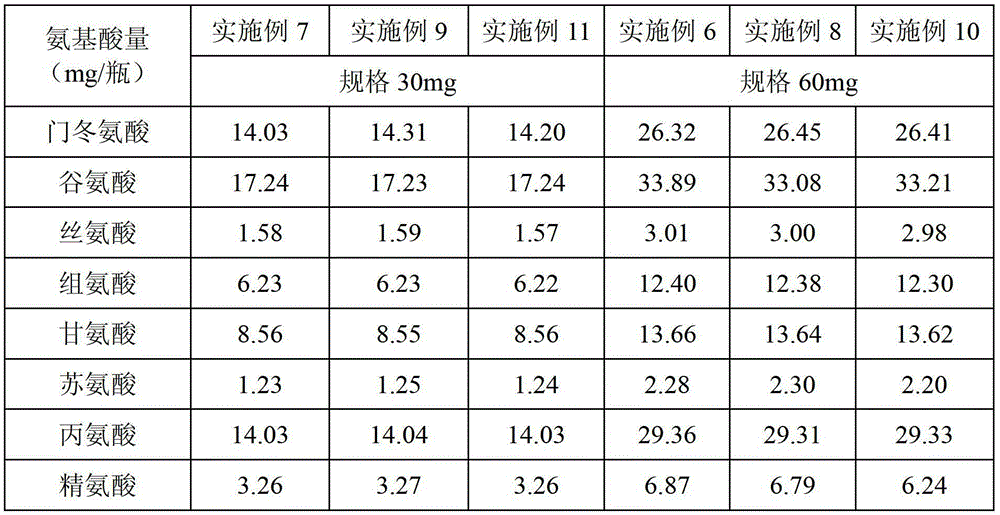

Method used

Image

Examples

Embodiment 1

[0037] The preparation of embodiment 1 cerebroprotein hydrolyzate

[0038] (1) Take fresh healthy pig brain, remove fat, homogenate, then vacuumize to 8Pa, keep the pressure for 10min, and then inject carbon dioxide to the pressure of 15MPa, keep the pressure for 22min;

[0039] (2) At 400rpm, slowly add the carbon dioxide-saturated fat-free brain pulp into the liquid carbon dioxide whose volume is 6.5 times the weight of the fat-free brain pulp. After adding, stir for 40 minutes, cool down to -75°C, keep for 3 hours, and then put it in 8 minutes. The temperature is raised to 45°C at a constant speed to vaporize the carbon dioxide;

[0040] (3) Add 3 times the weight of water for injection to the frozen-thawed brain pulp obtained in step 2, stir evenly, then add papain equivalent to 0.8% of the weight of the frozen-thawed brain pulp, and hydrolyze at 35°C for 3.5 hours to obtain an enzymatic hydrolyzate;

[0041] (4) Centrifuge the enzymatic hydrolyzate at 2500 rpm for 25 minut...

Embodiment 2

[0042] The preparation of embodiment 2 cerebroprotein hydrolyzate

[0043] (1) Take fresh healthy pig brain, remove fat, homogenate, then vacuumize to 5Pa, keep the pressure for 15min, and then inject carbon dioxide to the pressure of 10MPa, keep the pressure for 25min;

[0044] (2) Slowly add the degreased brain pulp saturated with carbon dioxide into the liquid carbon dioxide whose volume is 5 times the weight of the degreased brain pulp at a rotation speed of 300 rpm. After adding, stir for 60 minutes, cool down to -70°C, keep for 2 hours, and then lower the temperature for 5 minutes. Raise the temperature to 50°C to vaporize the carbon dioxide;

[0045] (3) Add 2 times the weight of water for injection to the frozen-thawed brain pulp obtained in step 2, stir evenly, then add papain equivalent to 0.5% of the weight of the frozen-thawed brain pulp, and hydrolyze at 40°C for 3 hours to obtain an enzymatic hydrolyzate;

[0046] (4) Centrifuge the enzymatic hydrolyzate at 2500...

Embodiment 3

[0047] The preparation of embodiment 3 cerebroprotein hydrolyzates

[0048] (1) Take fresh healthy pig brain, remove fat, homogenate, then vacuumize to 10Pa, keep the pressure for 5min, and then inject carbon dioxide to the pressure of 18MPa, keep the pressure for 20min;

[0049] (2) Slowly add the carbon dioxide-saturated defatted brain pulp into the liquid carbon dioxide whose volume is 8 times the weight of the defatted brain pulp at a rotation speed of 500 rpm. After adding, stir for 20 minutes, cool down to -80°C, keep for 4 hours, and then lower the temperature for 10 minutes. Raise the temperature to 40°C to vaporize the carbon dioxide;

[0050] (3) Add 4 times the weight of water for injection to the frozen-thawed brain plasma obtained in step 2, stir evenly, then add pepsin equivalent to 1% of the weight of the frozen-thawed brain plasma, and hydrolyze at 30°C for 4 hours to obtain an enzymatic hydrolyzate;

[0051] (4) Centrifuge the enzymatic hydrolyzate at 2500rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com