Airtight tyre material prepared by blending ecichloro-hydrin rubber with poly vinyl alcohol and preparation method of aright tyre material

An airtight material, polyvinyl chloride technology, which is applied in the field of tire airtight materials, can solve the problems of blending of epichloride rubber and polyvinyl chloride, etc., and achieve shortened vulcanization time, fast vulcanization speed, heat resistance and variable pressure resistance The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a car tire airtight material prepared by blending epichlorohydrin rubber and polyvinyl chloride, the specific steps are as follows:

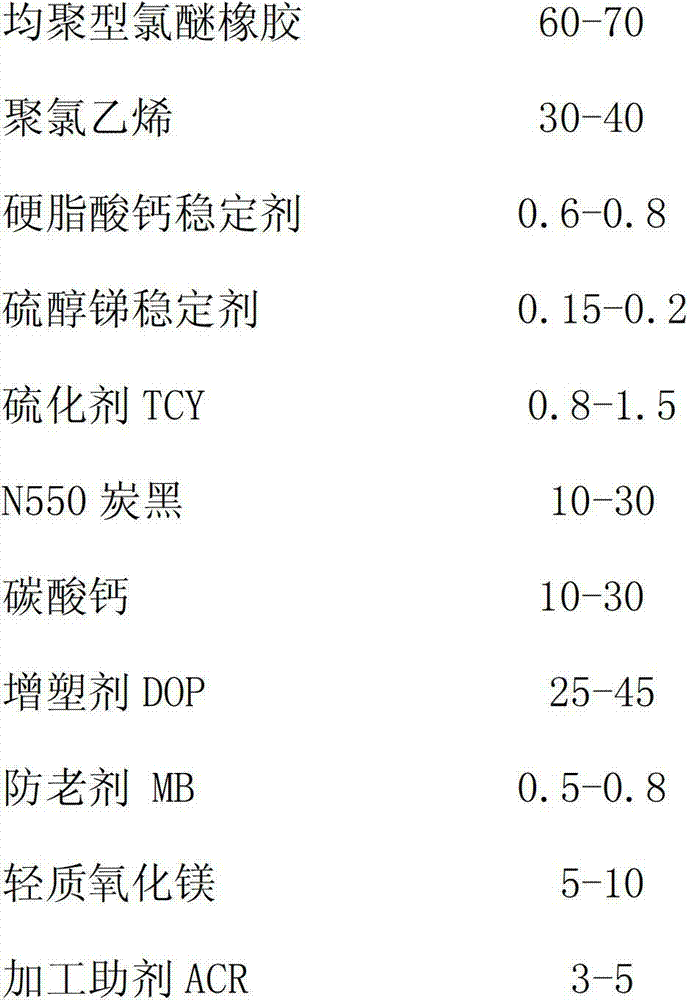

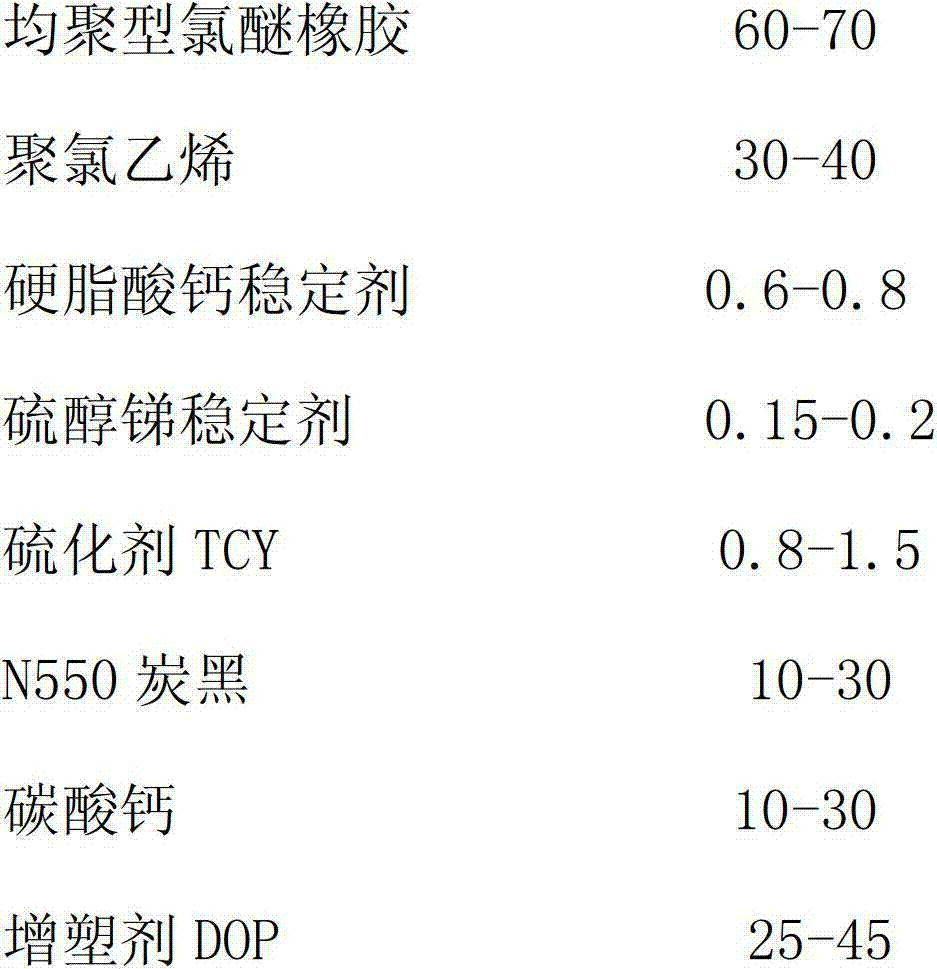

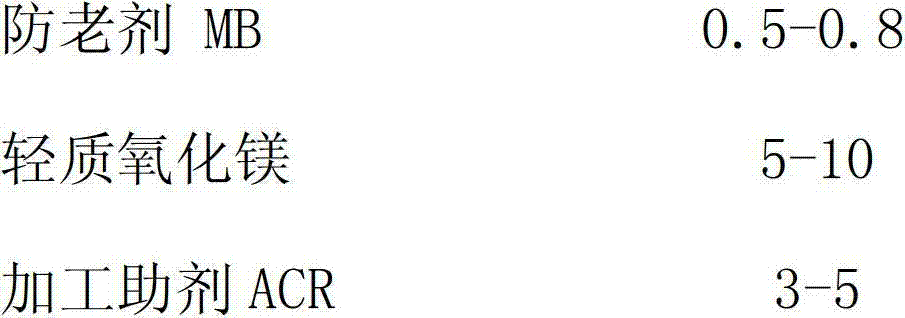

[0031] (1) Prepare the material raw materials of the following mass parts: 60 parts of homopolychloroether rubber, 40 parts of polyvinyl chloride, 0.8 part of calcium stearate stabilizer, 0.2 part of mercaptan antimony stabilizer, 0.8 part of thiocyanate Acid, 10 parts of N550 carbon black, 30 parts of calcium carbonate, 45 parts of dioctyl phthalate, 0.5 parts of antioxidant MB, 10 parts of magnesium oxide, 5 parts of processing aid ACR; wherein the processing aid ACR is acrylate and Copolymers of methacrylates;

[0032](2) Stir and heat 40 parts of polyvinyl chloride prepared in step (1) to 100±5°C with a high-speed mixing mixer, and then gradually add 45 parts of plasticizer DOP (dioctyl phthalate), When adding the plasticizer DOP, keep the temperature of the material at 100±5°C, put the polyvinyl chloride added...

Embodiment 2

[0035] A method for preparing a car tire airtight material prepared by blending epichlorohydrin rubber and polyvinyl chloride, the specific steps are as follows:

[0036] (1) Prepare the material raw materials of the following mass parts: 65 parts of homopolychloroether rubber, 35 parts of polyvinyl chloride, 0.7 part of calcium stearate stabilizer, 0.18 part of mercaptan antimony stabilizer, 1.0 part of 2.4.6- Trimercapto-1.3.5 triazine, 20 parts of N550 carbon black, 20 parts of calcium carbonate, 38 parts of dioctyl phthalate, 0.65 parts of antioxidant MB, 8 parts of magnesium oxide, 4 parts of processing aid ACR; Auxiliary ACR is a copolymer of acrylate and methacrylate;

[0037] (2) Stir and heat 35 parts of polyvinyl chloride prepared in step (1) to 100±5°C with a high-speed mixing mixer, and then gradually add 38 parts of plasticizer DOP (dioctyl phthalate), When adding the plasticizer DOP, keep the temperature of the material at 100±5°C, put the polyvinyl chloride add...

Embodiment 3

[0040] A method for preparing a car tire airtight material prepared by blending epichlorohydrin rubber and polyvinyl chloride, the specific steps are as follows:

[0041] (1) At first, the following material raw materials will be prepared in parts by mass: 70 parts of homopolychloroether rubber, 30 parts of polyvinyl chloride, 0.6 part of calcium stearate stabilizer, 0.15 part of mercaptan antimony stabilizer, 1.5 parts of tripolymer Thiocyanic acid, 30 parts of N550 carbon black, 10 parts of calcium carbonate, 25 parts of dioctyl phthalate, 0.8 parts of antioxidant MB, 5 parts of magnesium oxide, 3 parts of processing aid ACR; wherein the processing aid ACR is acrylic acid Copolymers of esters and methacrylates;

[0042] (2) Stir and heat 30 parts of polyvinyl chloride prepared in step (1) to 100±5°C with a high-speed mixing mixer, and then gradually add 25 parts of plasticizer DOP (dioctyl phthalate), When adding the plasticizer DOP, keep the temperature of the material at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com