Preparation method of long-life DSA (Dimension Stable Anode) electrode

A long-life, electrode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of reducing catalytic efficiency, increasing energy consumption, reducing electrode conductivity, etc., achieving simple process, improving service life, and improving catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Cut a titanium sheet with a thickness of 250 μm into 3×4cm 2 After being polished and washed with alkali, they were put into 10wt% oxalic acid, etched in a water bath at 100°C for 3 hours, then rinsed with deionized water and dried to obtain a titanium sheet with a clean surface.

[0018] (2) With the treated titanium sheet as the cathode and the stainless steel sheet as the anode, first put the 3 citric acid solution at 15mA / cm 2 Electroplating at a current density of 2min, and then transferred to a solution containing 0.09M SnCl 4 in sulfuric acid solution at 20mA / cm 2 Electroplating at a current density of 20min; repeat the above steps twice, rinse and dry it and bake it at 500°C for 2h.

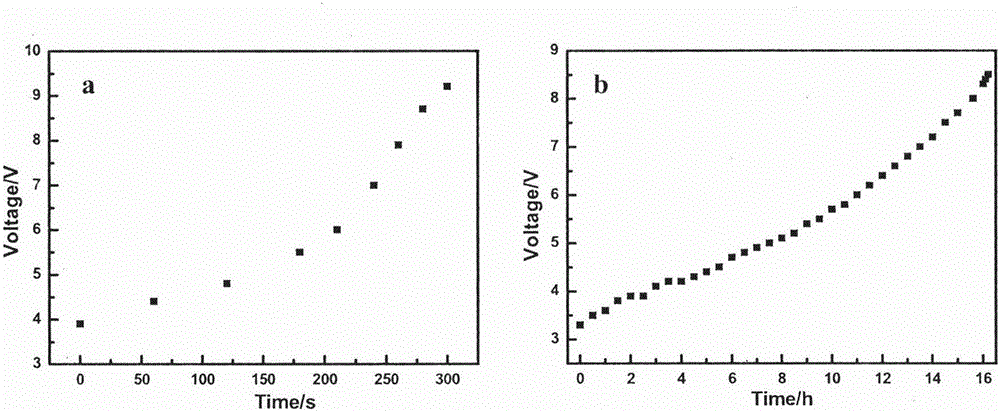

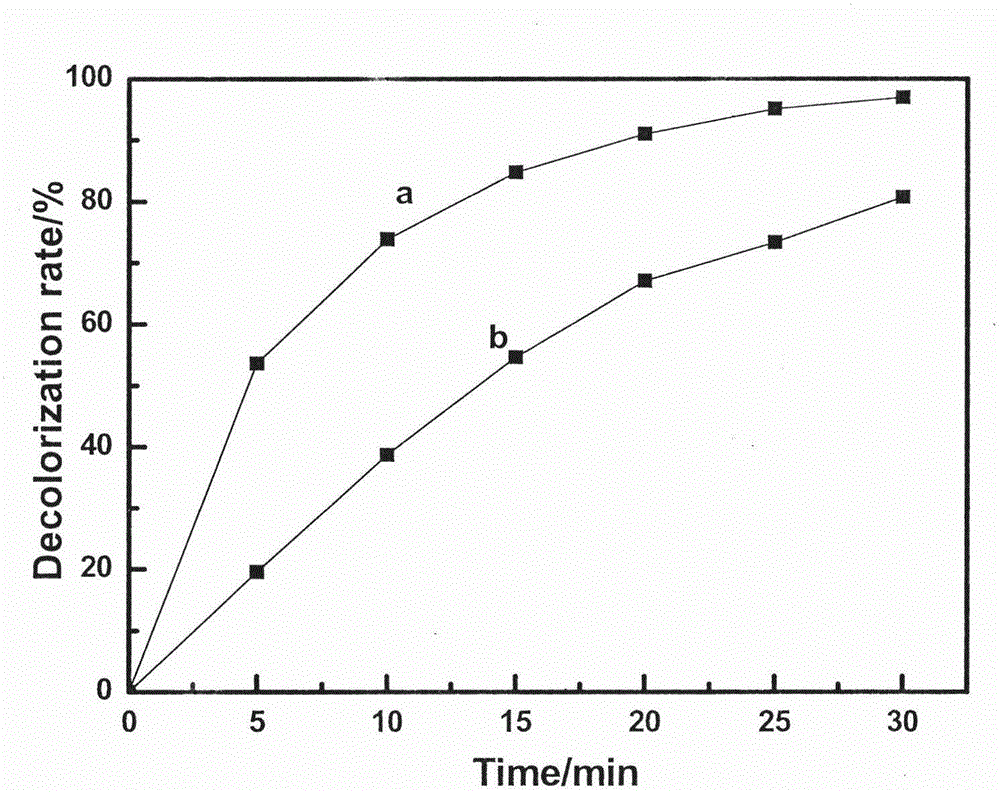

[0019] (3) Configure a n-butanol solution with a Sn:Sb:Ce molar ratio of 100:10:3, use the dipping and pulling method to evenly coat the active layer on the surface of the titanium sheet with the intermediate layer plated, and dry it at 120°C. Heat treatment at 450°C for 10...

Embodiment 2

[0022] (1) Cut a titanium sheet with a thickness of 250 μm into 3×4cm 2 After polishing and alkaline washing, put them into 10wt% oxalic acid, etch in a water bath at 100°C for 3 hours, then rinse them with deionized water and dry them to obtain a titanium sheet with a clean surface, which is then used as an anode , nickel sheet as the cathode, in the HF, H 2 O and CH 3 Anodized at a voltage of 20V for 20min in an electrolyte composed of COOH, and calcined at 500°C for 3h.

[0023] (2) The titanium sheet treated in step (1) is used as the cathode, and the stainless steel sheet is used as the anode, and the titanium sheet containing 0.01M SbCl 3 and 0.1M SnCl 4 In the citric acid solution, at 10mA / cm 2 Electroplating at a current density of 1h, rinsed and dried, then baked at 500°C for 2h.

[0024] (3) Configuration Sn: Sb: Ce molar ratio is the ethylene glycol solution of 100:10:3, the active layer is evenly brushed on the surface of the titanium plate that has electropla...

Embodiment 3

[0027] (1) Cut the titanium mesh into 2×2cm 2 After ultrasonic degreasing by alkaline cleaning, put it into 10wt% oxalic acid, etch in a water bath at 100°C for 3 hours, then rinse it with deionized water and dry it to obtain a titanium mesh with a clean surface.

[0028] (2) The titanium mesh treated in step (1) is used as the cathode, and the stainless steel sheet is used as the anode, and the titanium mesh containing 0.01M SbCl 3 and 0.1M SnCl 4 In the citric acid solution, at 10mA / cm 2 Electroplating at a current density of 1h, rinsed and dried, then baked at 500°C for 2h.

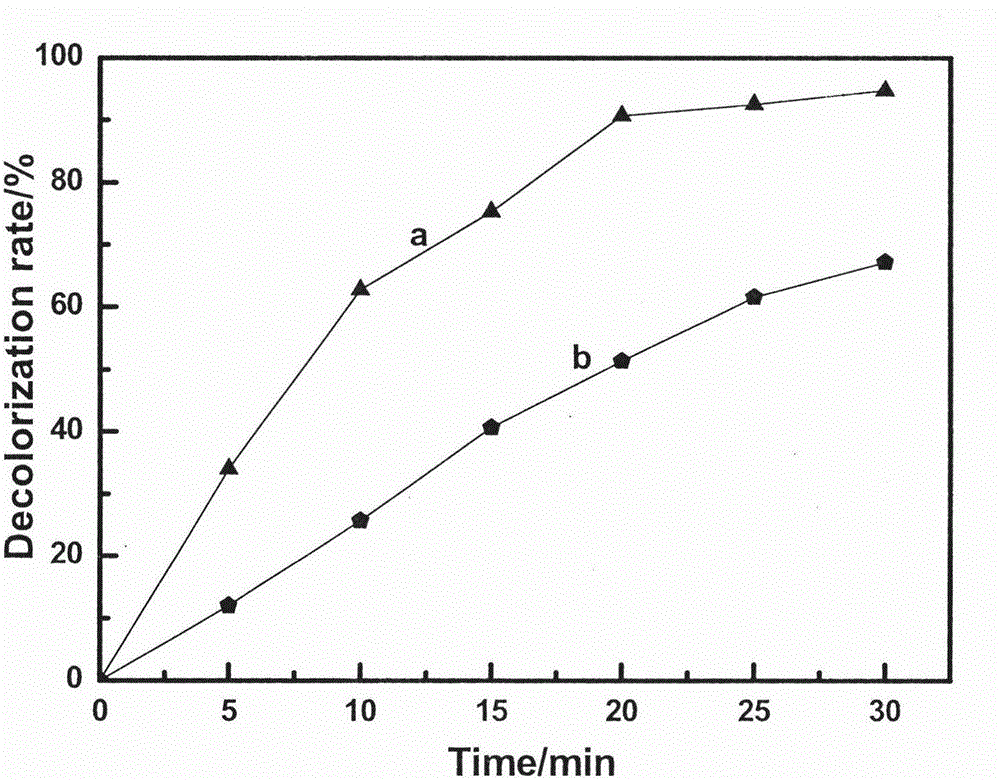

[0029] (3) The titanium mesh electroplated with the tin-antimony intermediate layer was used as the anode, and the clean titanium mesh of the same size was used as the cathode. Under the condition of 40°C water bath, the titanium mesh was heated at 20mA / cm in a saturated NaOH solution of PbO. 2 The current density electrodeposition 1h; then containing 0.5MPb (NO 3 ) 2 and 40mMNaF nitric acid solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com