Continuous culture and filtration system for crystals

A filter system and crystal technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of difficult to guarantee crystal quality, slow crystal growth rate, low crystal yield, etc., achieve low dislocation, improve growth Effect of speed and quality, high optical uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

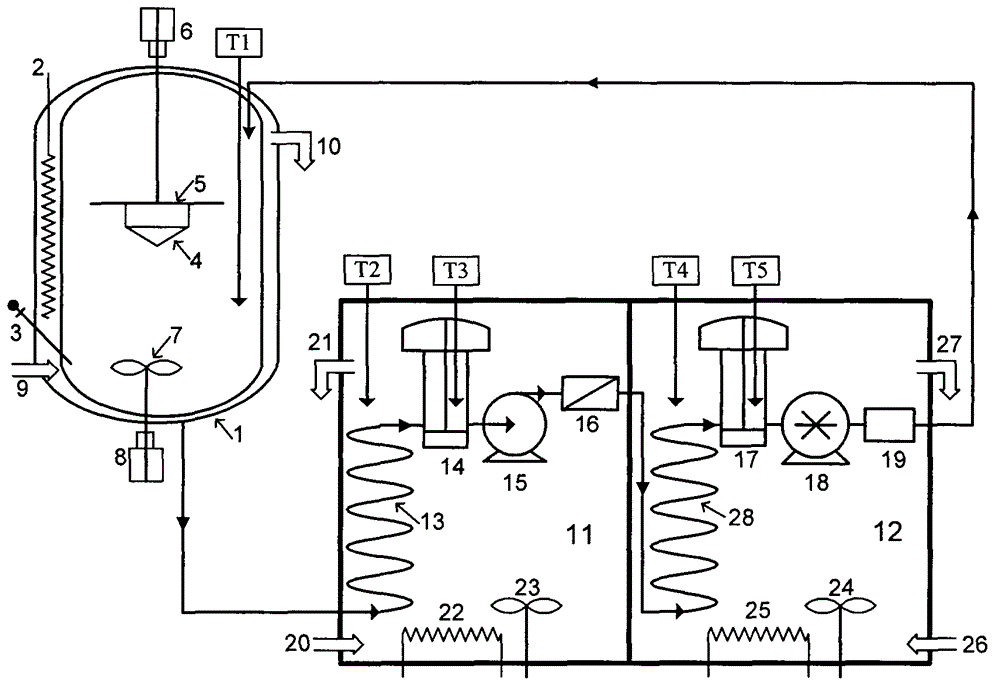

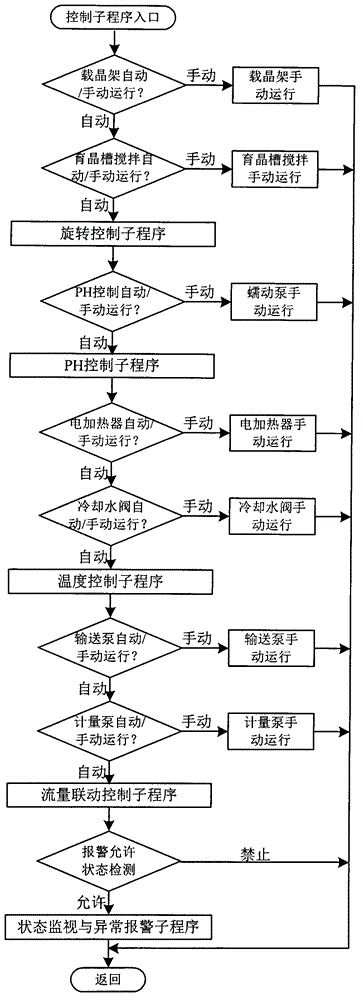

[0018] The specific implementation of the patent of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] An application of a crystal continuous culture and filtration system, comprising the following implementation process:

[0020] (1) After putting in the solution, turn on the power, and the system will enter the automatic operation state. If it is the first time to turn on the machine, temperature control is required, and the settings include: Δ of the hot water bath 1 , The lower limit of delivery pump start Δ 2 , Δ of the equilibrium water bath 3 with the starting upper limit of the metering pump Δ 4 Value (Δ refers to the deviation value from the crystal growth tank temperature T1).

[0021] (2) There are two control tasks of the crystal growth tank rotation control subsystem. One is to control the rotation of the stirrer at the bottom of the crystal growth tank to make the solution rotate, reduce the thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com