Novel high-speed two-for-one twister control system and method based on brushless direct current motors

A brushed DC motor, control system technology, applied in spinning machine, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of low working efficiency of AC induction motor, unsatisfactory yarn forming effect, high performance requirements, etc. problems, to achieve the effect of significant energy saving, light weight and wide speed range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

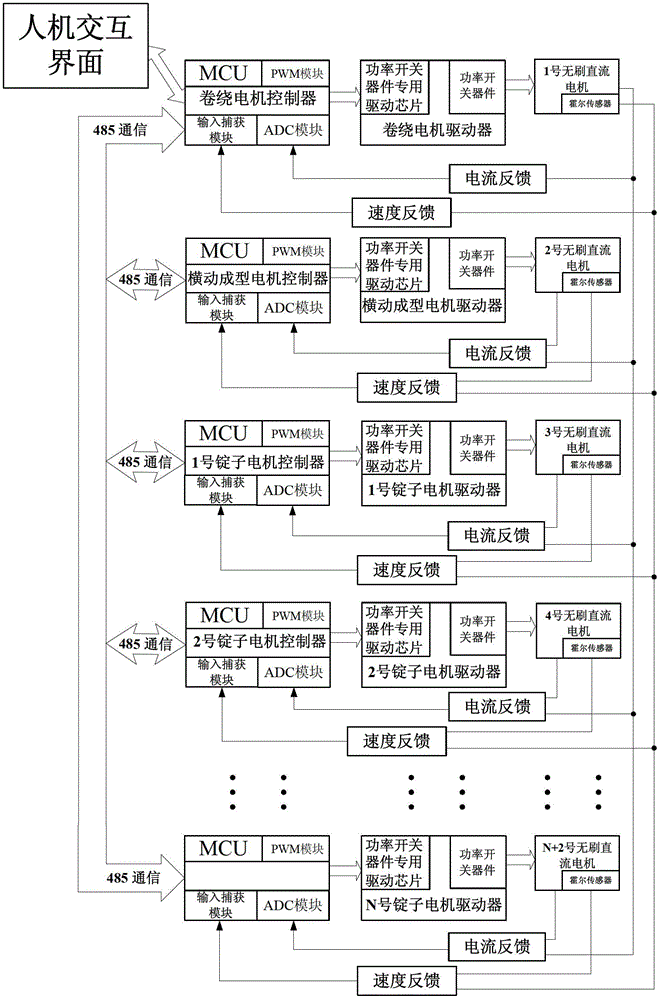

[0011] As shown in Figure 1, the new high-speed two-for-one twister control system based on brushless DC motors includes a human-computer interaction interface module, a winding motor controller module, a traverse forming motor controller module, a plurality of spindle motor controller modules, and a winding motor controller module. Winding motor driver module, traverse forming motor driver module, multiple spindle motor driver modules and multiple brushless DC motors; described winding motor controller module, traverse forming controller module and multiple spindle motor controller modules ARM processor STM32F103 is adopted, and the winding motor driver module, traverse forming motor driver module, and multiple spindle motor driver modules adopt IPM power driver module; each control circuit includes a controller module, a driver module and a wireless For the brushed DC motor, the PWM output pins of the controller module are connected to the signal input pins of the driver modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com