Light emitting diode and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor thermal conductivity of silver glue, high cost, and not being widely used, so as to improve the operating life and reduce light attenuation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

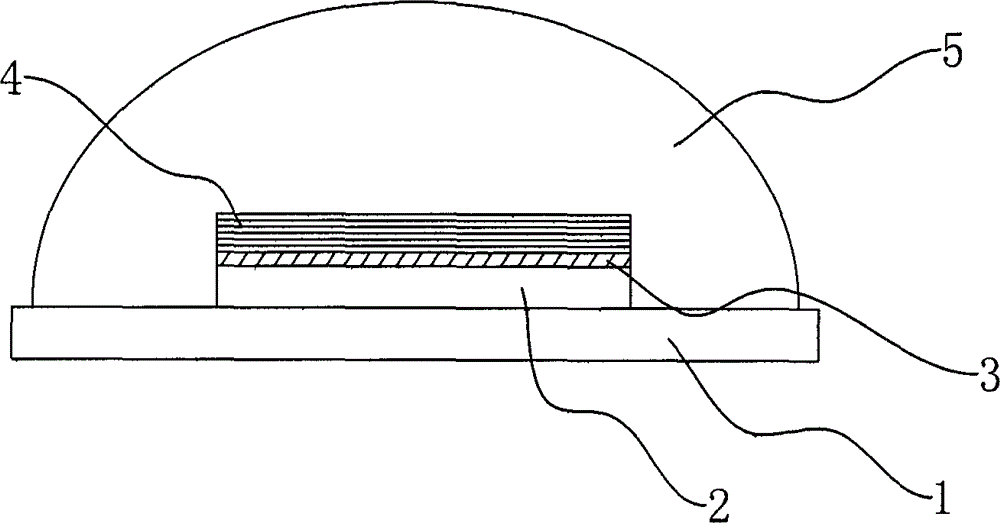

[0039] Such as figure 1 In the light-emitting diode structure shown, the light-emitting diode chip 2 adopts a blue light-emitting diode chip, the light-emitting layer 3 adopts fluorescent powder that is excited by blue light to generate yellow light, and the metal nanomaterial coating layer 4 adopts gold nanowires, and the gold nanowires are coated The thickness of the layer is 40 nm.

[0040] The preparation method is as follows:

[0041] ①Choose a suitable die-bonding glue to bond the LED chip to the base;

[0042] ② Lead out the electrodes on the light-emitting diode chip;

[0043] ③ Coating phosphor powder on the LED chip;

[0044] ④ preparing the gold nanowire coating layer on the upper surface of the light-emitting layer obtained in step ③;

[0045] ⑤ encapsulating the light-emitting diode prepared above;

[0046] ⑥ Test the photoelectric properties and parameters of the device.

Embodiment 2

[0048] Such as figure 1 In the light-emitting diode structure shown, the light-emitting diode chip 2 adopts a blue light-emitting diode chip, the light-emitting layer 3 adopts phosphor powder excited by blue light to generate green light, and the metal nanomaterial coating layer 4 adopts copper nanowires, and the copper nanowires are coated The thickness of the layer is 50 nm.

[0049] The preparation process is similar to Example 1.

Embodiment 3

[0051] Such as figure 1 In the light-emitting diode structure shown, the light-emitting diode chip 2 adopts a blue light-emitting diode chip, the light-emitting layer 3 adopts phosphor powder excited by blue light to generate red light, and the metal nanomaterial coating layer 4 adopts nickel nanowires, and the nickel nanowires are coated The thickness of the layer is 60 nm.

[0052] The preparation process is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com