Method for producing hydrophilized microparticles

A technology of hydrophilization and microparticles, applied in the field of preparation of hydrophilic microparticles, can solve the problem of no research on the coloring of polymer particles, and achieve the effect of inhibiting the discoloration and high hydrophilization of vinyl polymer microparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

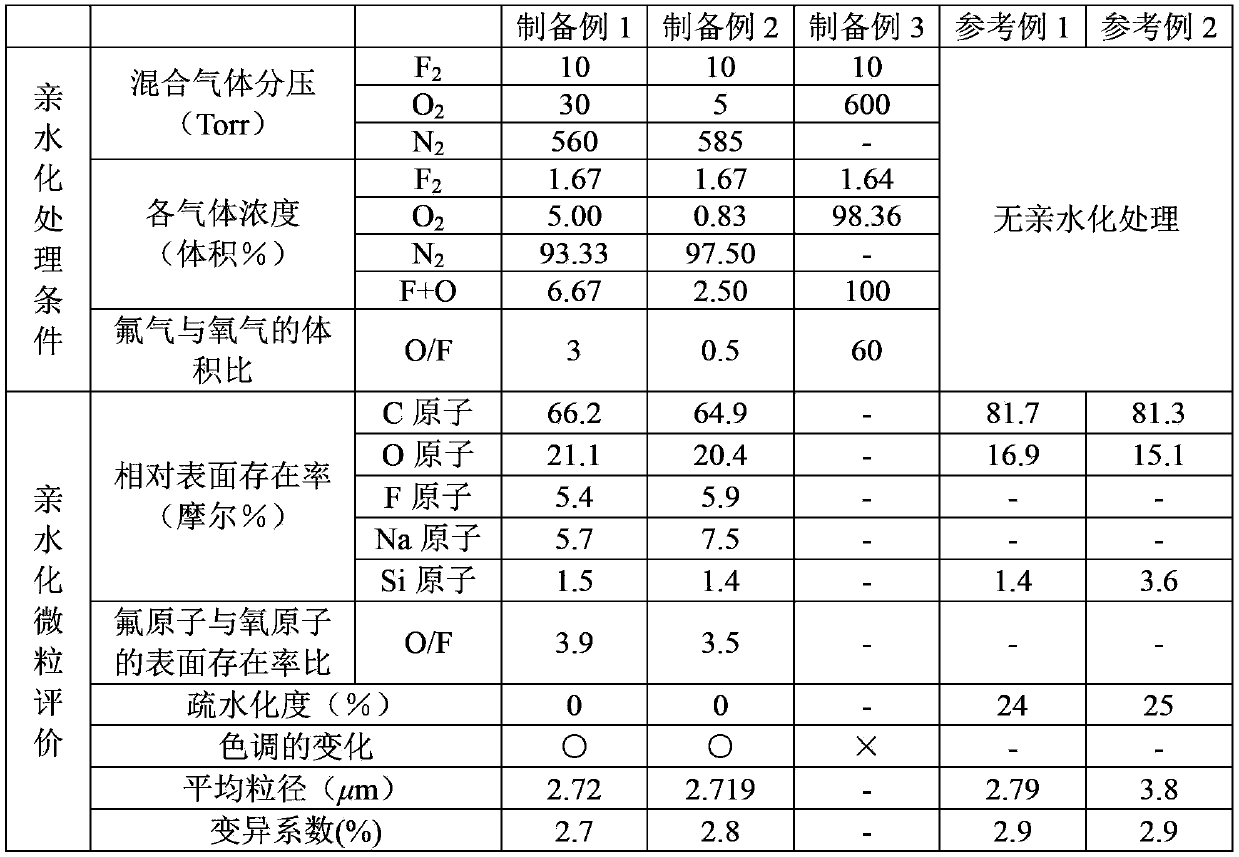

preparation example Construction

[0013] In the production method of the present invention, a mixed gas containing fluorine gas, a gas containing an oxygen atom-containing compound, and an inert gas is brought into contact with the substrate particles to hydrophilize the surface of the substrate particles. It is considered that by this treatment, hydrogen bonded to carbon is replaced by oxygen and fluorine to form -C(F)=O, after which some or all of them are converted into carboxyl groups. Therefore, a plurality of -C(F)=O and / or carboxyl groups are generated near the surface of the hydrophilized microparticles, and the hydrophilicity is significantly improved. In addition, while generating the -C(F)=O or carboxyl group, a reaction in which a part of the C-H bond in the particle skeleton is converted into a C-F bond also proceeds. In addition, the presence of these functional groups or bonds can be confirmed by an X-ray photoelectron analysis device (ESCA) or the like.

[0014] 1. Mixed gas

[0015] In the p...

Embodiment

[0092] The following examples are given to describe the present invention more specifically. However, the present invention is not limited to the following examples, and can be appropriately modified and implemented within the scope of the above-mentioned and following gist, and these are also included in the present invention. within the technical range. In addition, in the following, unless otherwise specified, "part" means "mass part", and "%" means "mass %". Various measurement and evaluation methods were performed as follows.

[0093] 1. Evaluation method

[0094] 1-1. Average particle size

[0095] The particle diameters of 30,000 particles were measured using a precision particle size distribution measuring device (trade name: "Colter Malchizer III", manufactured by Beckman Coulter Co., Ltd.), and the average particle diameter and standard deviation based on the number of particles were determined. The coefficient of variation (CV value) of the particle diameter was ...

preparation example 1

[0118] 120 parts of the above-obtained substrate particle No. 1 were charged into a chamber-type processing apparatus with a capacity of 500 L. The particle layer has a thickness of 0.5 mm. After the chamber is decompressed to 1Pa, the mixed gas is introduced to make the fluorine (F 2 ) gas / oxygen (O 2 ) gas / nitrogen (N 2 ) gas = 1.33kPa (10torr) / 3.99kPa (30torr) / 74.48kPa (560torr). Thereafter, after processing at 40° C. for 60 minutes, the inside of the chamber was replaced with nitrogen and returned to atmospheric pressure.

[0119] Then, 120 parts of the obtained mixed gas-treated particles were dispersed in a 1% by mass aqueous sodium hydroxide solution (particle concentration: 6.7%), and alkali treatment was performed at 80° C. for 3 hours while stirring. After the particles were filtered, they were dispersed in ion-exchanged water at 80° C. (particle concentration: 6.7% by mass), and washed at the same temperature for 3 hours. After cooling to room temperature, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com