Fe-doped TiO2 nanotube photocatalyst, and preparation method and application thereof

A photocatalyst and nanotube technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve complex preparation process and process, nanotube limitation, ratio Small surface area and other issues, to achieve the effect of no secondary pollution, many adsorption points, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 1.0g P-25TiO 2 powder and 0.0505g of Fe(NO 3 ) 3 9H 2 O, added to 16.0mL of 10mol / L NaOH solution, magnetically stirred for 0.5h, transferred to a polytetrafluoroethylene beaker, reacted at 105°C for 24h, removed and cooled to room temperature, washed with distilled water until neutral. Soak in 0.1mol / L hydrochloric acid for 0.5h, wash again until neutral, dry at 60°C, calcinate in a muffle furnace at 550°C for 2h, and grind to obtain Fe-doped nanotube TiO with an atomic doping amount of 1%. 2 catalyst. The above P-25TiO 2 Powder was purchased from Degussa Corporation, New Jersey. The TiO 2 Powder specific surface area is 50m 2 / g, the average particle size is 21nm, anatase and rutile account for 80% and 20% of the total mass respectively.

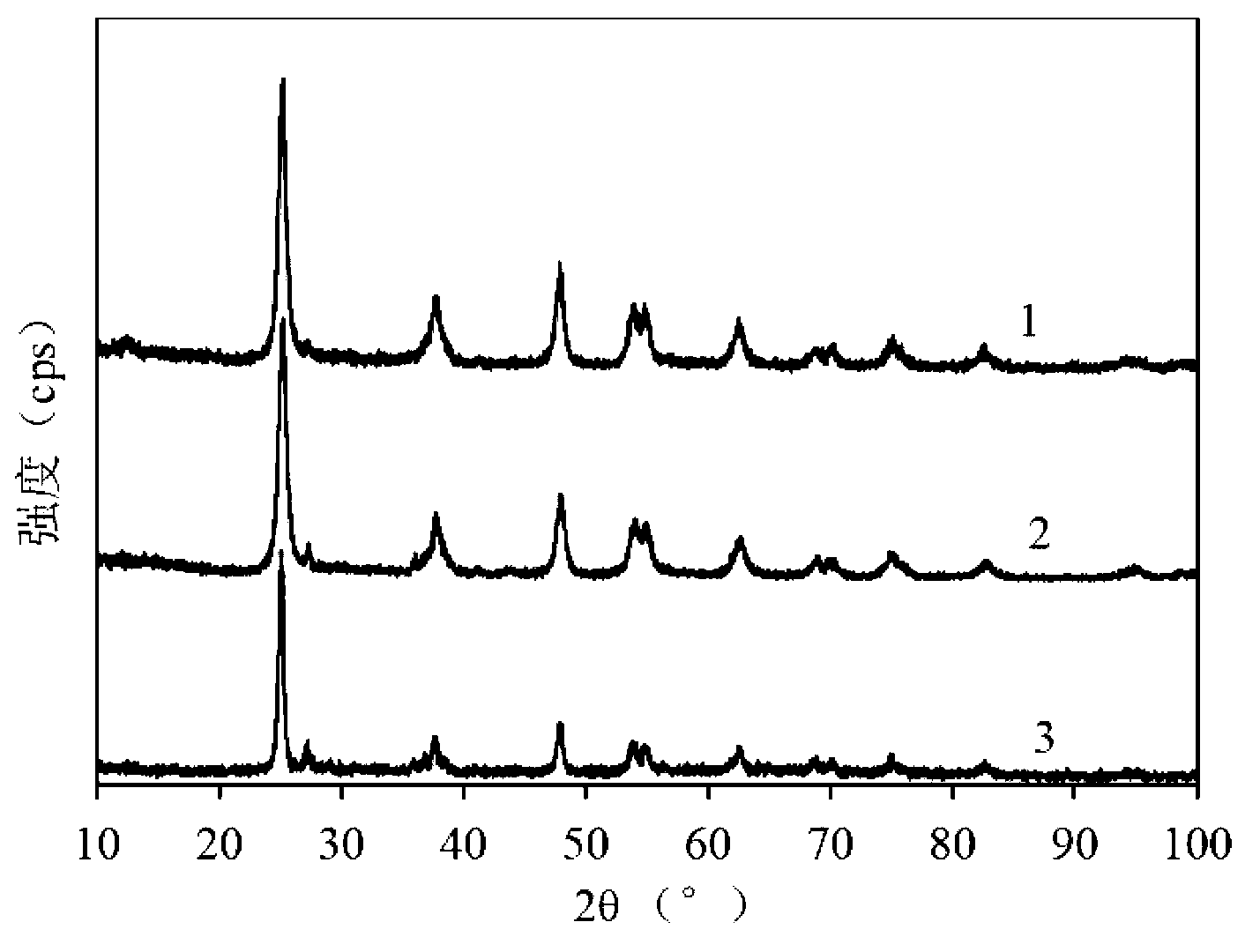

[0034] Analysis of calcined Fe-doped nanotube TiO at 550°C using Rigaku Dmax-RB rotating anode diffractometer (X-ray diffraction, XRD) 2 Crystal phase (Cu Kα target, λ=0.1506nm); ( figure 1 ), the results show that t...

Embodiment 2

[0037] Weigh 1.0g P-25TiO 2 powder and 0.0505g of Fe(NO 3 ) 3 9H 2O, added to 16.0mL of 10mol / L NaOH solution, magnetically stirred for 0.5h, transferred to a polytetrafluoroethylene beaker, reacted at 105°C for 24h, removed and cooled to room temperature, washed with distilled water until neutral. Soak in 0.1mol / L hydrochloric acid for 0.5h, wash again until neutral, dry at 60°C, calcinate in a muffle furnace at 450°C for 2h, and grind to obtain Fe-doped nanotube TiO with an atomic doping amount of 1%. 2 catalyst. The above P-25TiO 2 Powder was purchased from Degussa Corporation, New Jersey. The TiO 2 Powder specific surface area is 50m 2 / g, the average particle size is 21nm, anatase and rutile account for 80% and 20% of the total mass respectively.

[0038] Analysis of calcined Fe-doped nanotube TiO at 450°C using Rigaku Dmax-RB rotating anode diffractometer (X-ray diffraction, XRD) 2 Crystal phase (Cu Kα target, λ=0.1506nm); ( figure 1 ), the results show that th...

Embodiment 3

[0041] Weigh 1.0g P-25TiO 2 powder and 0.0505g of Fe(NO 3 ) 3 9H 2 O, added to 16.0mL of 10mol / L NaOH solution, magnetically stirred for 0.5h, transferred to a polytetrafluoroethylene beaker, reacted at 105°C for 24h, removed and cooled to room temperature, washed with distilled water until neutral. Soak in 0.1mol / L hydrochloric acid for 0.5h, wash again until neutral, dry at 60°C, calcinate in a muffle furnace at 500°C for 2h, and grind to obtain Fe-doped nanotube TiO with an atomic doping amount of 1%. 2 catalyst. The above P-25TiO 2 Powder was purchased from Degussa Corporation, New Jersey. The TiO 2 Powder specific surface area is 50m 2 / g, the average particle size is 21nm, anatase and rutile account for 80% and 20% of the total mass respectively.

[0042] Analysis of calcined Fe-doped nanotube TiO at 500℃ using Rigaku Dmax-RB rotating anode diffractometer (X-ray diffraction, XRD) 2 Crystal phase (Cu Kα target, λ=0.1506nm); ( figure 1 ), the results show that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com