Modified plastics and preparation method thereof

A technology for plastics and modification, applied in the field of modified plastics and their preparation, can solve problems such as the preparation of modified plastics that have never been seen before, and achieve the effects of low cost, wide source and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

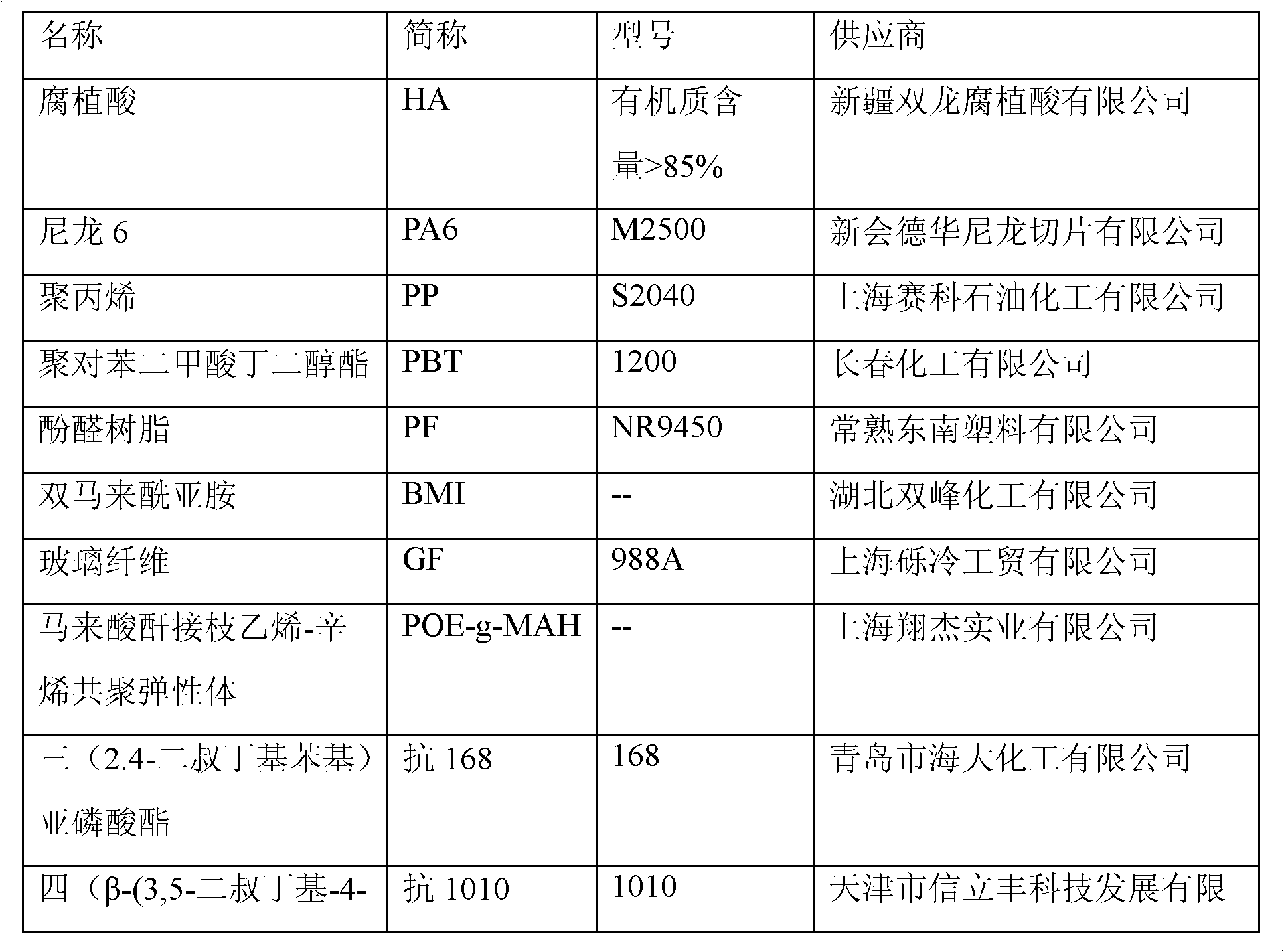

Method used

Image

Examples

Embodiment 1

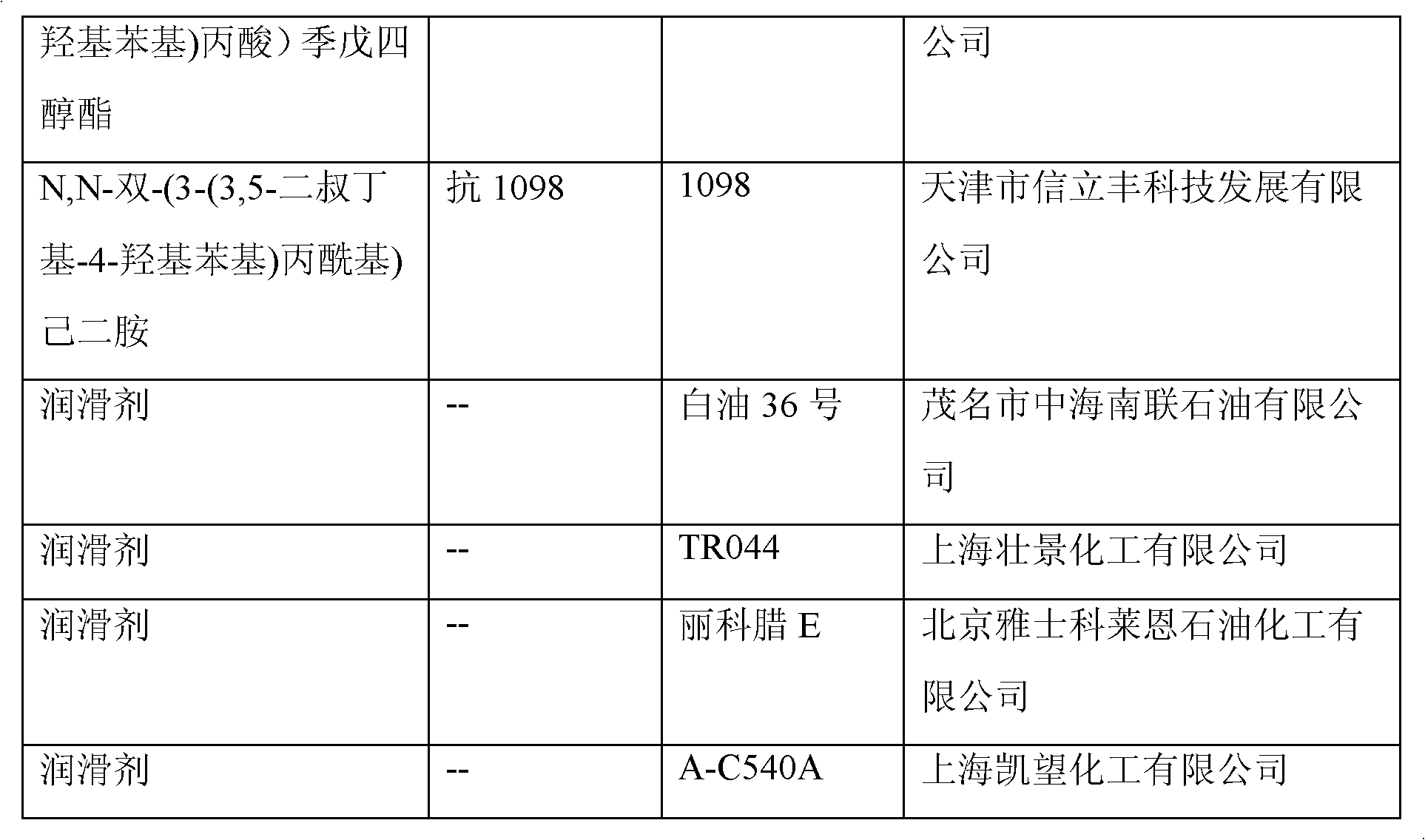

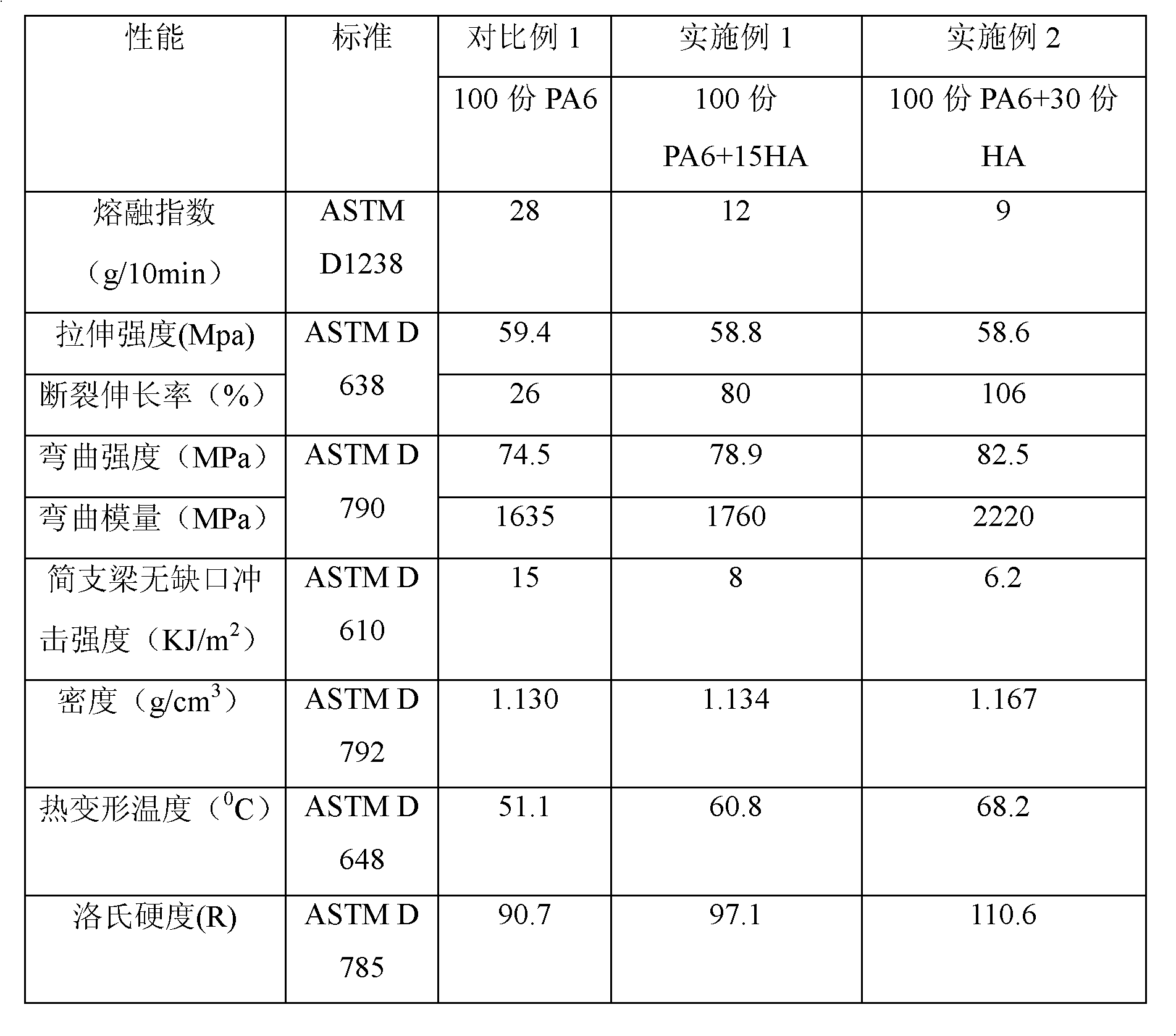

[0040] Weigh 100 parts of PA6 of M2500, 15 parts of HA, 0.02 parts of anti-1098, 0.02 parts of anti-168, 0.05 parts of lubricant TR044, mix in a high-speed mixer for 5 minutes, and extrude the uniformly mixed material in a twin-screw extruder out of granulation.

[0041] The temperature of the extruder is set to: 200°C in zone I, 220°C in zone II, 235°C in zone III, 240°C in zone IV, 235°C in zone V, 235°C in zone VI, and 240°C at the head. After the material is extruded, it is cooled by water, Cut into pellets, dry the pellets at 100°C for 3 hours, make a sample strip by an injection molding machine, and place it at a constant temperature of 25°C for 16 hours before testing. The performance test results are shown in Table 2.

Embodiment 2

[0043] Weigh 100 parts of M2500 PA6, 30 parts of HA, 0.02 parts of anti-1098, 0.02 parts of anti-168, 0.05 parts of lubricant TR044, mix in a high-speed mixer for 5 minutes, and extrude the uniformly mixed material in a twin-screw extruder out of granulation.

[0044] The temperature of the extruder is set to: 200°C in zone I, 220°C in zone II, 235°C in zone III, 240°C in zone IV, 235°C in zone V, 235°C in zone VI, and 240°C at the head. After the material is extruded, it is cooled by water, Cut into pellets, dry the pellets at 100°C for 3 hours, make a sample strip by an injection molding machine, and place it at a constant temperature of 25°C for 16 hours before testing. The performance test results are shown in Table 2.

Embodiment 3

[0052] Weigh 100 parts of S2040 PP, 20 parts of HA, 0.03 part of anti-1098, 0.03 part of anti-168, 0.03 part of 36# white oil, mix in a high-speed mixer for 5 minutes, and put the uniformly mixed material in a twin-screw extruder Extrusion granulation.

[0053] The extruder temperature setting is: 180°C in zone I, 190°C in zone II, 195°C in zone III, 200°C in zone IV, 205°C in zone V, 210°C in zone VI, and 215°C at the head. After extrusion, the material is cooled by water, Cut into pellets, dry the pellets at 100°C for 3 hours, make a sample by an injection molding machine, and place it at a constant temperature of 25°C for 16 hours before testing. The performance test results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com