Method of developing substructure MBE (molecular beam epitaxy) with same mass on side wall of GaAs nanowire

A sidewall growth and nanowire technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem that the optical and magnetic characterization has not been significantly developed, the density and position cannot be quantitatively controlled, electrical, Optical property crosstalk and other issues, to achieve the effect of good optical properties and single photon emission characteristics, high repeatability, and good three-dimensional confinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

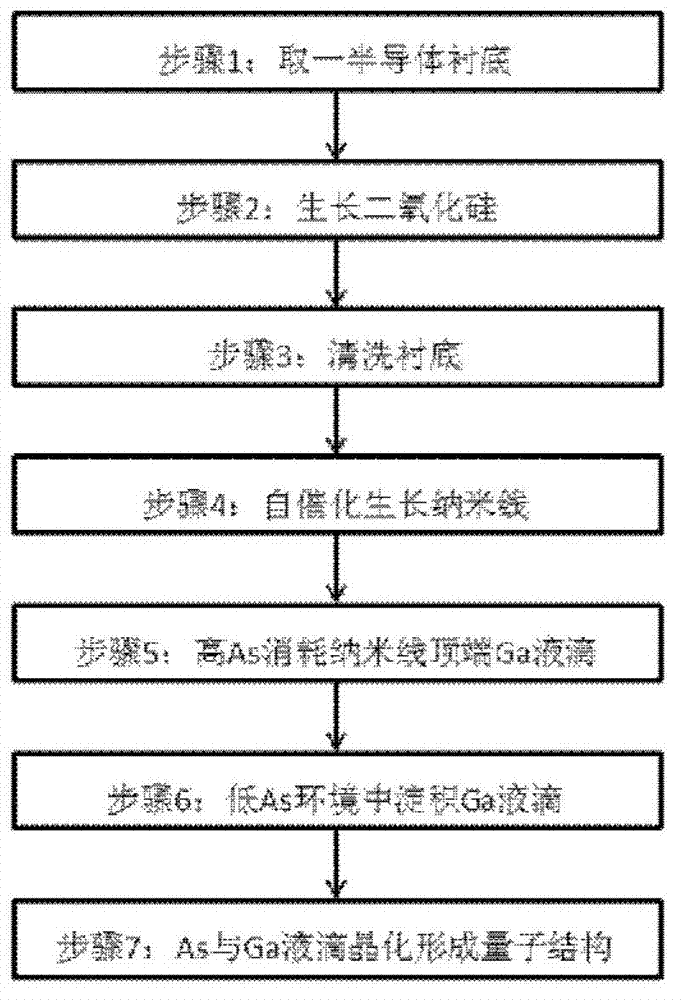

[0028] see figure 1 and figure 2 As shown, the present invention provides a kind of MBE method that grows homogeneous quantum structure on GaAs nanowire sidewall, comprises the steps:

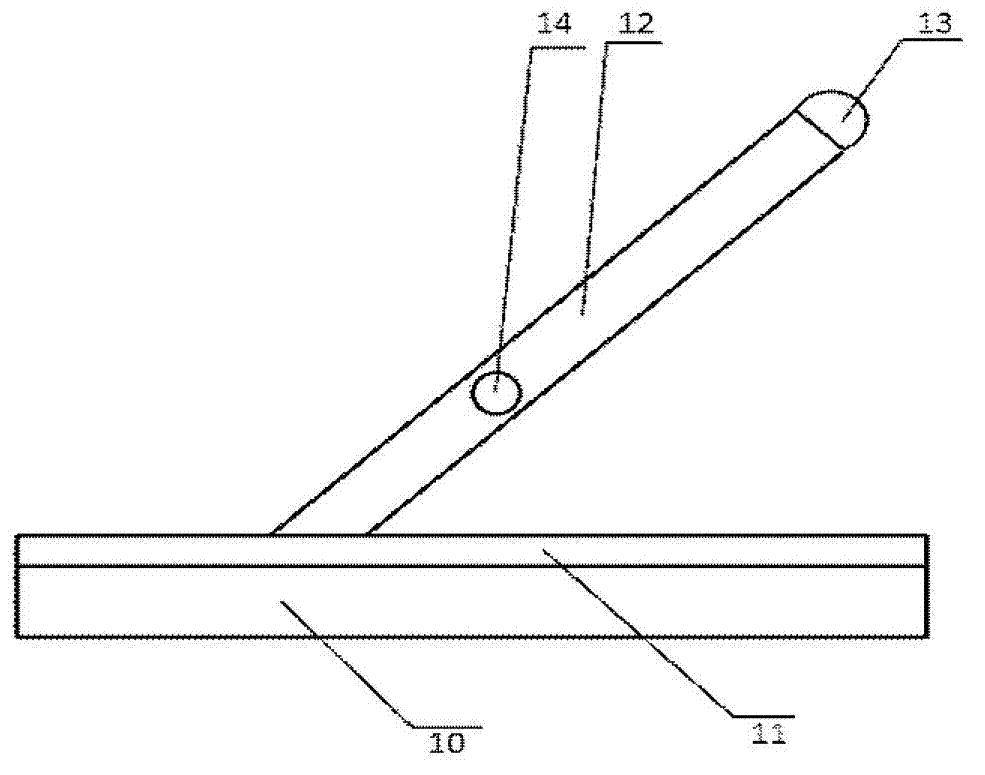

[0029] Step 1: Take a semiconductor substrate 10, and the material of the semiconductor substrate 10 is GaAs(001) or GaAs(111)B. It should be noted that, in addition to gallium arsenide GaAs, the selected substrate material may also be semiconductor materials such as silicon Si.

[0030] Step 2: growing a silicon dioxide layer (SiO2) on the semiconductor substrate 10 2 ) 11, adopting the method of ion beam sputtering, the thickness of the silicon dioxide layer 11 is 10-20nm. Preparation of SiO 2 There are many ways of layer 11, the basic principle is to be able to precisely control the thickness of the thin layer, too thick SiO 2 Layer 11 will result in no nanowire growth on the surface or a small amount of nanowires with no fixed orientation. Grown SiO 2 Before layer 11, if the GaAs su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com