Graphene polyaniline composite and preparation method thereof, and lithium ion battery

A composite material and graphene technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve problems such as improvement, lack of adhesion, and unfavorable energy density of electrode sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

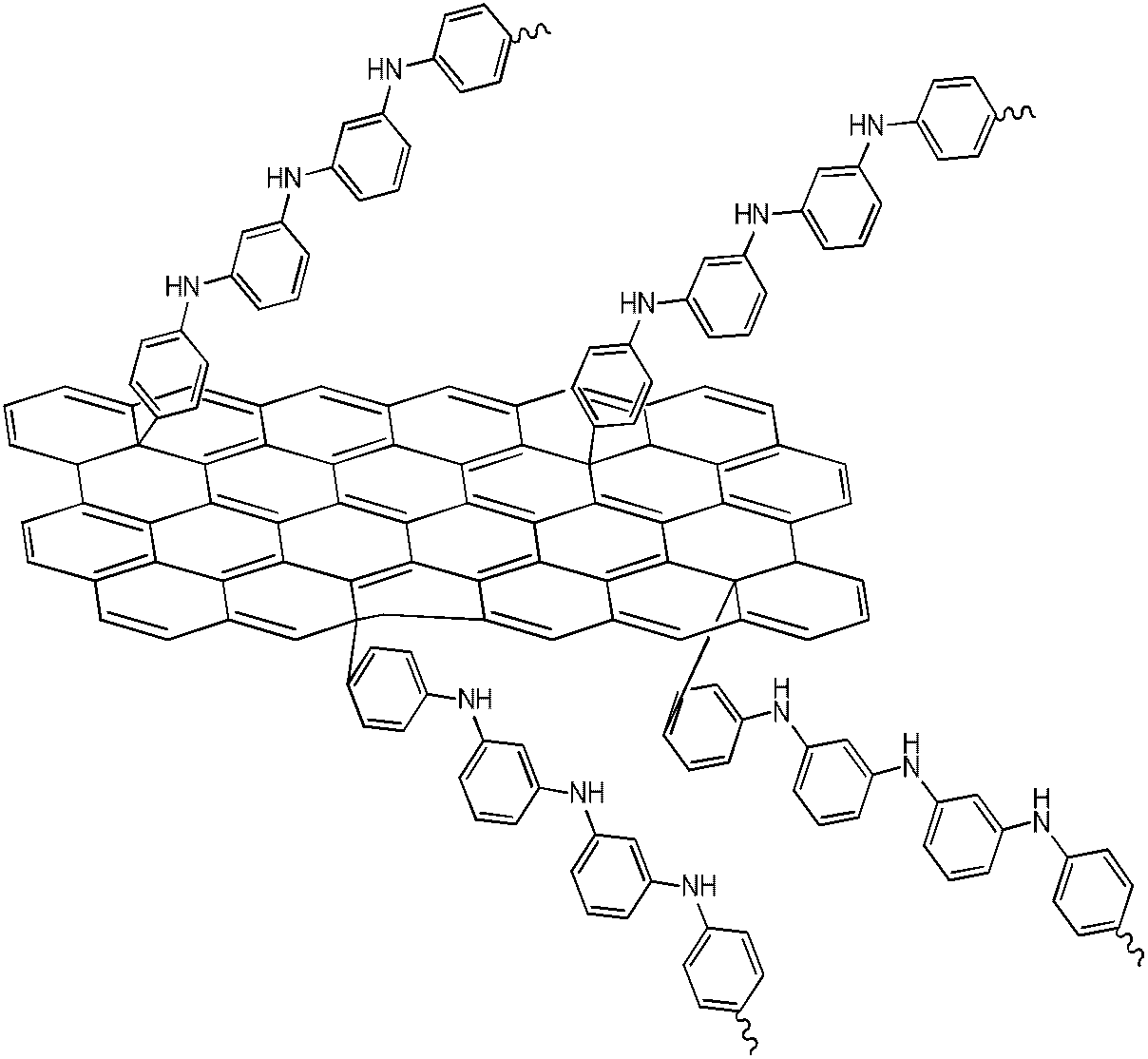

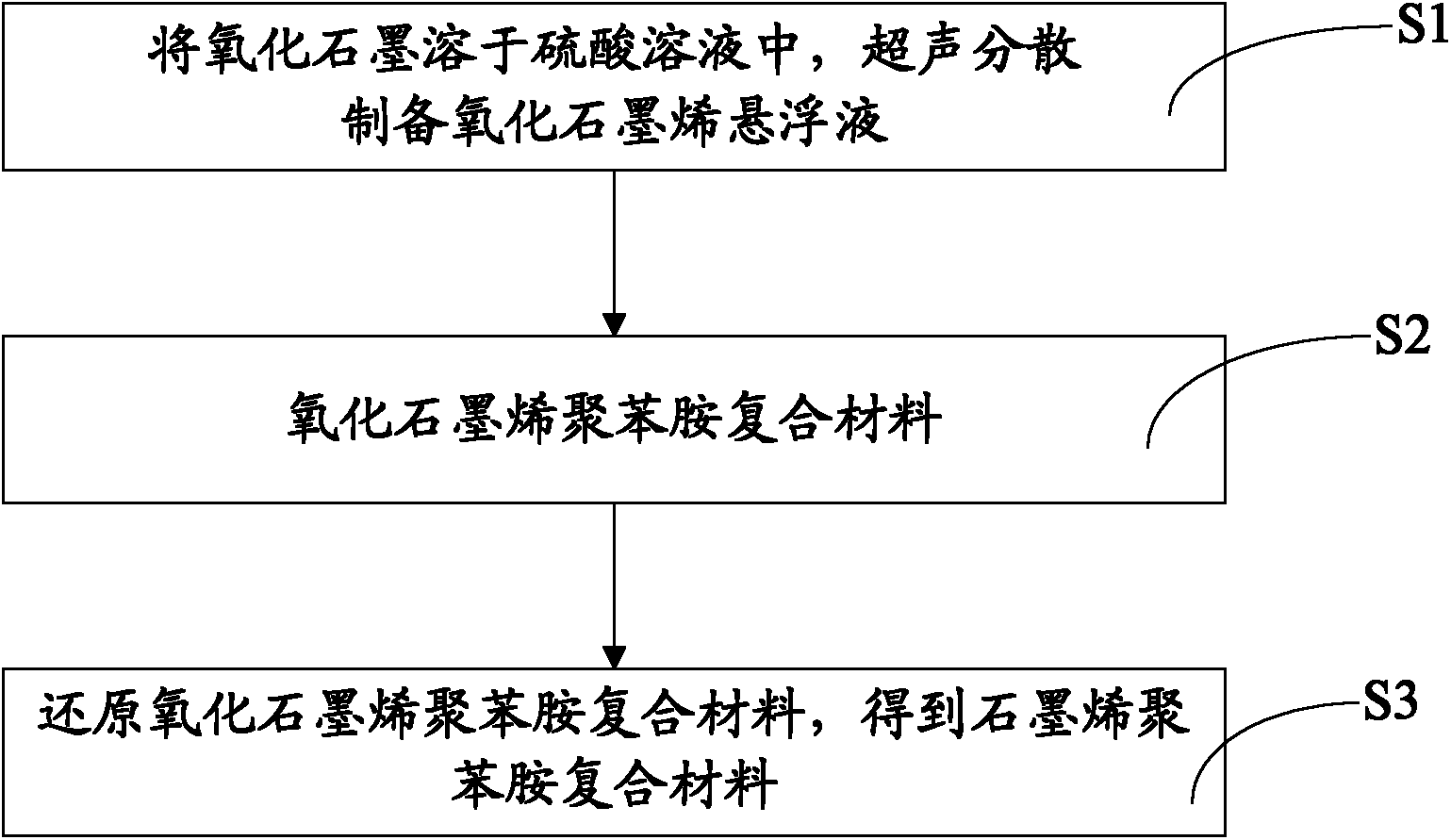

[0028] In addition, this embodiment also provides a preparation method of graphene-polyaniline composite material, such as image 3 shown, including the following steps:

[0029] Step S1: dissolving graphite oxide in water and ultrasonically dispersing to prepare graphene oxide suspension.

[0030] Wherein, the concentration of the graphene oxide suspension is controlled at 0.1-1g / L.

[0031] Further, the graphite oxide in this step is preferably prepared in the following steps:

[0032] Add graphite raw materials, potassium persulfate and phosphorus pentoxide to concentrated sulfuric acid at 80°C, stir evenly, cool for more than 6 hours, filter with suction, wash until neutral, and dry to obtain a mixed sample; then add the mixed sample to 0 In the concentrated sulfuric acid at ℃, add potassium permanganate, keep the temperature of the system below 20 ℃, then keep it in an oil bath at 35 ℃ for 30 minutes, then slowly add deionized water, and then add hydrogen peroxide solut...

Embodiment 1

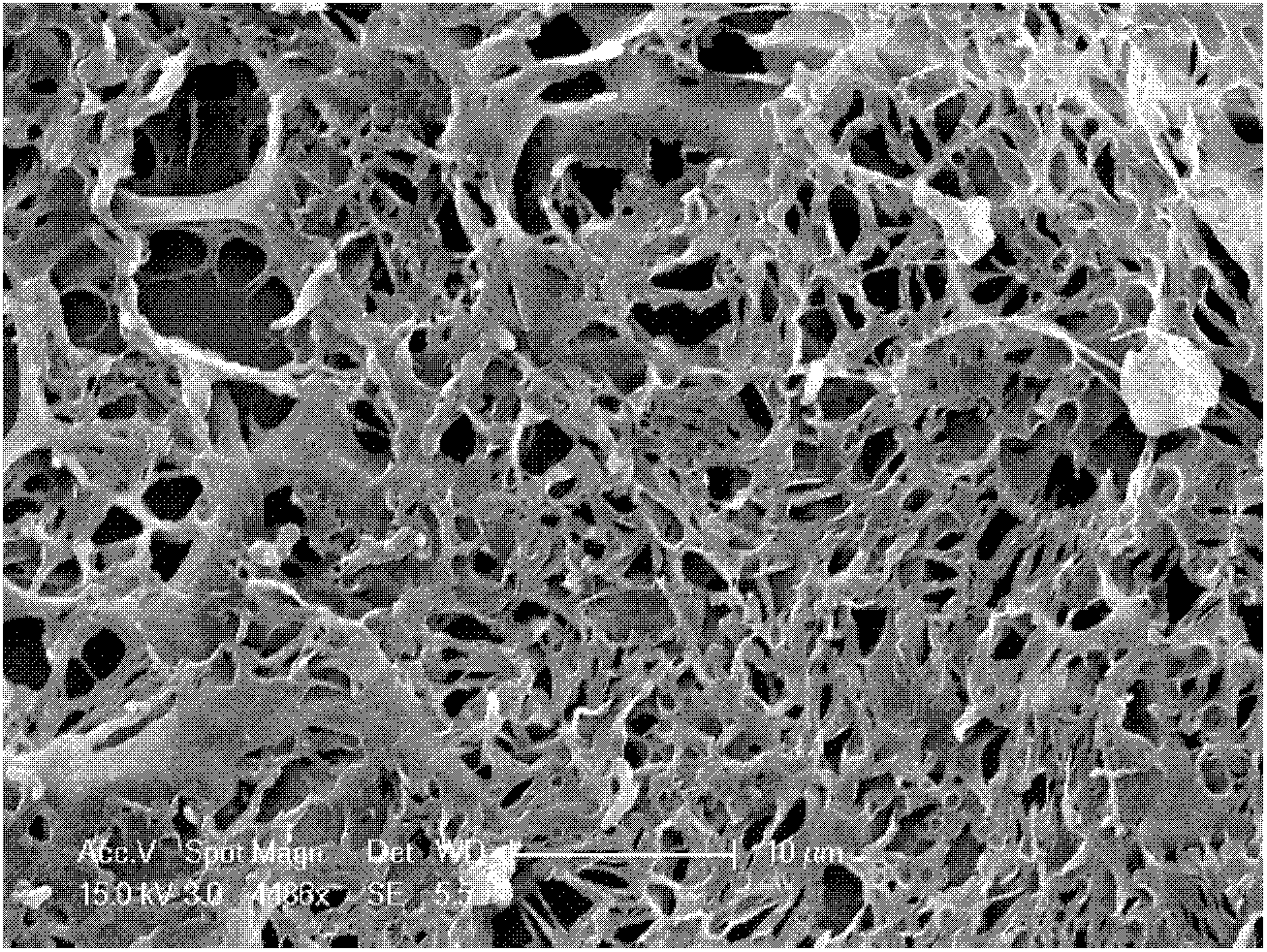

[0044] The technological process of the graphene-polyaniline composite material of the present embodiment is as follows:

[0045]Graphite → graphite oxide → graphene oxide polyaniline composite → graphene polyaniline composite

[0046] (1) Graphite: 50 mesh natural flake graphite with a purity of 99.5%.

[0047] (2) Graphite oxide: Add 20g of graphite, 10g of potassium persulfate and 10g of phosphorus pentoxide into concentrated sulfuric acid at 80°C, stir evenly, cool for more than 6 hours, filter with suction, wash until neutral, and dry to obtain a mixed sample;

[0048] Add the dried mixed sample to 230mL of concentrated sulfuric acid at 0°C, then add 60g of potassium permanganate, keep the temperature of the system below 20°C, then keep it in an oil bath at 35°C for 2 hours, then slowly add 920mL Deionized water;

[0049] After 15 minutes, add 2.8L of deionized water to the system until the color of the mixture turns bright yellow, filter while hot, then wash with 5L of...

Embodiment 2

[0056] (1) Graphite: 50 mesh natural flake graphite with a purity of 99.5%.

[0057] (2) Graphite oxide: Add 20g of graphite, 10g of potassium persulfate and 10g of phosphorus pentoxide into concentrated sulfuric acid at 80°C, stir evenly, cool for more than 6 hours, filter with suction, wash until neutral, and dry to obtain a mixed sample;

[0058] Add the dried mixed sample to 230mL of concentrated sulfuric acid at 0°C, then add 60g of potassium permanganate, keep the temperature of the system below 20°C, then keep it in an oil bath at 35°C for 2 hours, then slowly add 920mL Deionized water;

[0059] After 15 minutes, add 2.8L of deionized water to the system until the color of the mixture turns bright yellow, filter while hot, then wash with 5L of 10% hydrochloric acid, filter with suction, and dry in vacuum at 60°C for 48 hours That is to obtain graphite oxide, wherein the above-mentioned 2.8L deionized water contains 50mL of 30% hydrogen peroxide.

[0060] (3) Graphene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com