High-efficiency antimicrobial thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and high-efficiency technology, applied in the field of high-efficiency antibacterial thermoplastic elastomer and its preparation, can solve the problems of toxic decomposition products, strong surface polarity, shortened antibacterial life, etc., and achieve stable performance without changing mechanical properties and processing properties. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

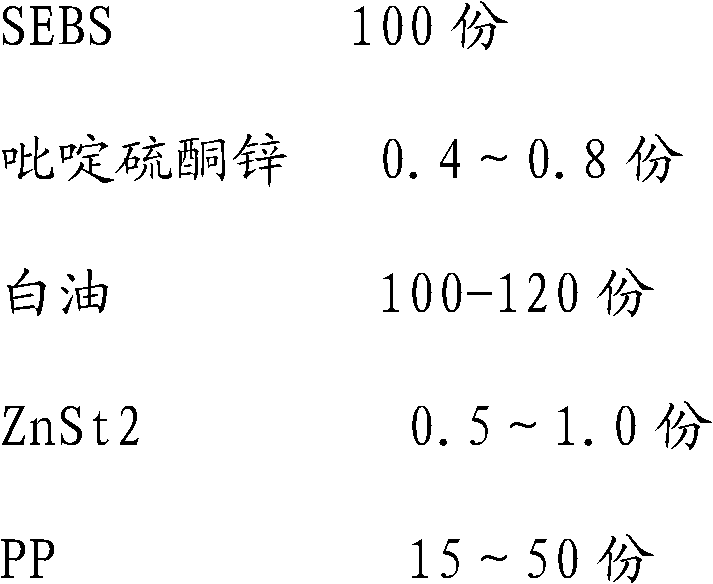

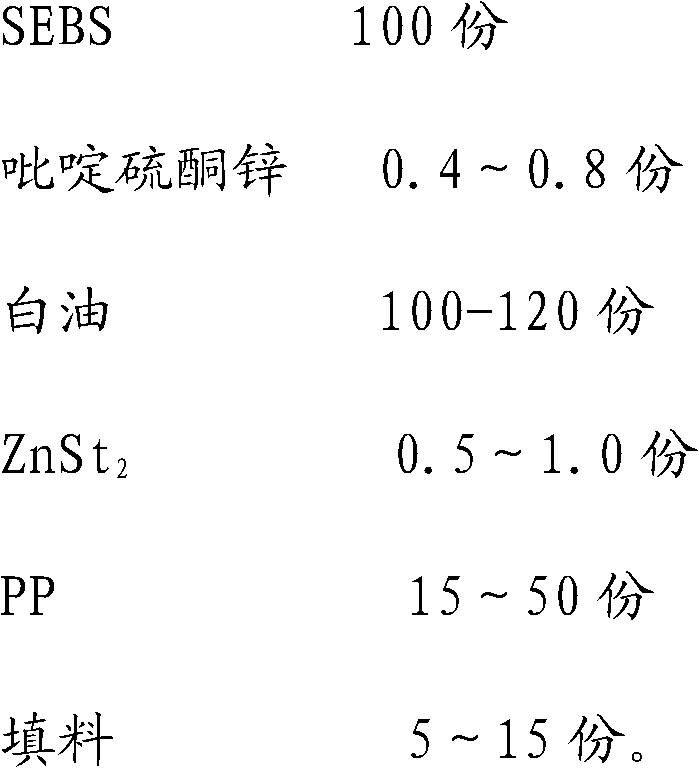

Method used

Image

Examples

Embodiment 1

[0036] Mix 50 kg of SEBS and 60 kg of white oil and stir evenly; mix 7.5 kg of PP resin, 1g of ZnSt, 10 kg of light active CaCO 3 and 0.2 kg of zinc pyrithione were added to the high-speed mixer in turn, and fully stirred and mixed; fully stirred and mixed under high-speed stirring, when the temperature rose to 50 ° C, stopped stirring, and took the material; fully stirred and pre-plasticized The mixture is Mixing and plasticizing on a twin-screw extruder, extruding to obtain the product of the present invention, the process conditions of the extruder are: 185°C in the first zone, 195°C in the second zone, 200°C in the third zone, 205°C in the fourth zone, and 210°C in the fifth zone ℃, 210℃ in the sixth zone, 200℃ in the seventh zone, 190℃ in the eighth zone, and 195℃ in the machine head.

Embodiment 2

[0038] Mix 50 kg of SEBS and 52 kg of white oil and stir evenly; mix 10 kg of PP resin, 1.7 g of ZnSt 2 , 5 kg of light active CaCO 3 and 0.6 kg of pyrithione zinc were added to the high-speed mixer in turn, and fully stirred and mixed; under high-speed stirring, fully stirred and mixed, when the temperature rose to 50 ° C, stopped stirring, and took the material; fully stirred the pre-plasticized mixture Mixing, plasticizing and extruding on a twin-screw extruder to obtain the product of the present invention. The process conditions of the extruder are: 185°C in the first zone, 195°C in the second zone, 200°C in the third zone, 205°C in the fourth zone, and 205°C in the fifth zone 210°C, 210°C in the sixth zone, 200°C in the seventh zone, 190°C in the eighth zone, and 195°C at the machine head. .

Embodiment 3

[0040] Mix 60 kg of SEBS and 60 kg of white oil and stir evenly; mix 15 kg of PP resin, 1.8g of ZnSt 2 , 18 kg of light active CaCO 3 and 0.35 kg of pyrithione zinc were added to the high-speed mixer in turn, and fully stirred and mixed; under high-speed stirring, fully stirred and mixed, when the temperature rose to 50 ° C, stopped stirring, and took the material; fully stirred the pre-plasticized mixture Mixing, plasticizing and extruding on a twin-screw extruder to obtain the product of the present invention. The process conditions of the extruder are: 185°C in the first zone, 195°C in the second zone, 200°C in the third zone, 205°C in the fourth zone, and 205°C in the fifth zone 210°C, 210°C in the sixth zone, 200°C in the seventh zone, 190°C in the eighth zone, and 195°C at the machine head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com