Solar battery back silver slurry and preparing method thereof

A technology for solar cells and back silver paste, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of poor adhesion and contact between back silver paste and substrate The problem of high resistance, to achieve the effect of increasing adhesion and solderability, reducing contact resistance, and good printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

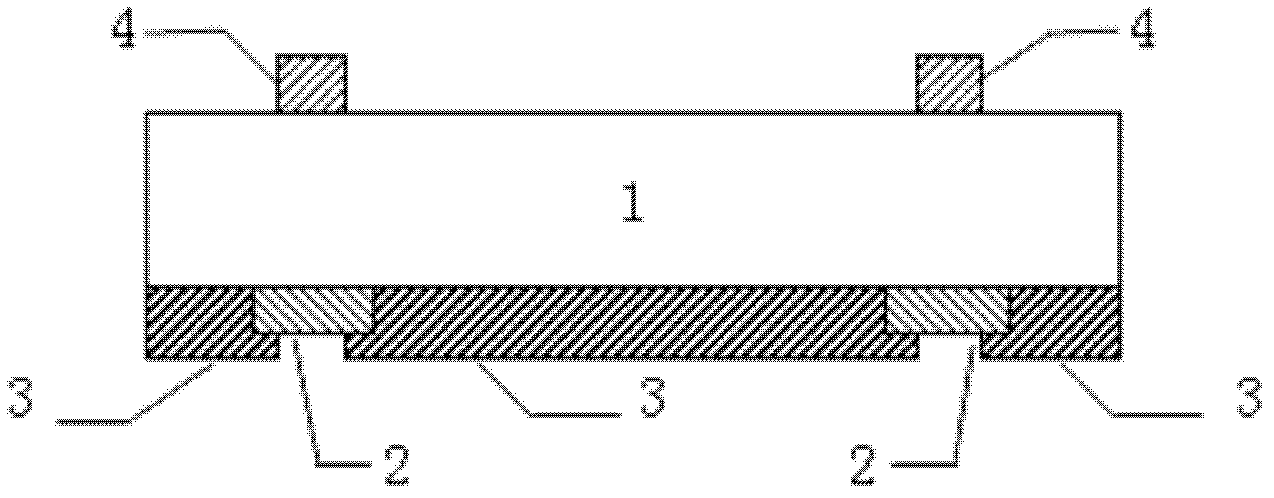

Image

Examples

preparation example Construction

[0043] Correspondingly, the present invention also provides a kind of preparation method of back silver paste for solar cell, comprises the following steps: Bi 2 o 3 , B 2 o 3 , La 2 o 3 , ZnO, Al 2 o 3 and SiO 2 According to the weight ratio (49~71): (4~8): (1~3): (2~9): (3~7): (16~32) mixing, through hot melting, cooling, ball milling and passing Obtain lead-free glass powder after sieving; Spherical silver powder, organic carrier, solvent, plasticizer, auxiliary agent, inorganic additive and described lead-free glass powder are by weight (50~70):(12~30):( 7-10): (1-3): (0.5-2): (0.2-3): (2-8) mixed, dispersed and then filtered to obtain back silver paste for solar cells.

[0044] In the above preparation process, the present invention adjusts the contact resistance and battery conversion efficiency of silver and silicon after sintering by adjusting the ratio of lead-free glass powder and silver powder; by adjusting the ratio of organic carrier to solvent, thereby ad...

Embodiment 2~5

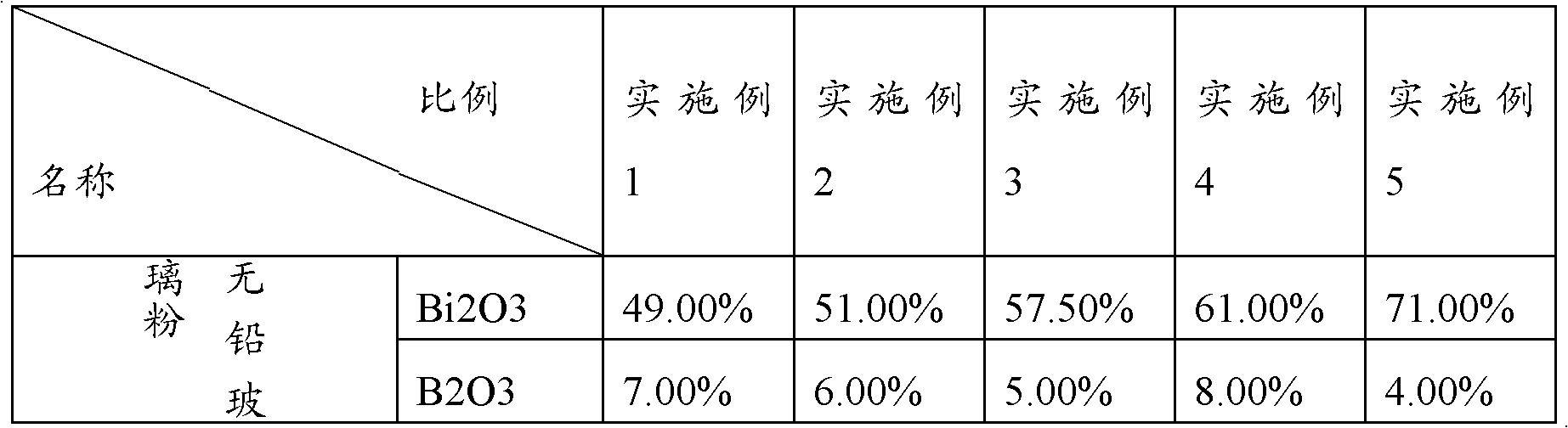

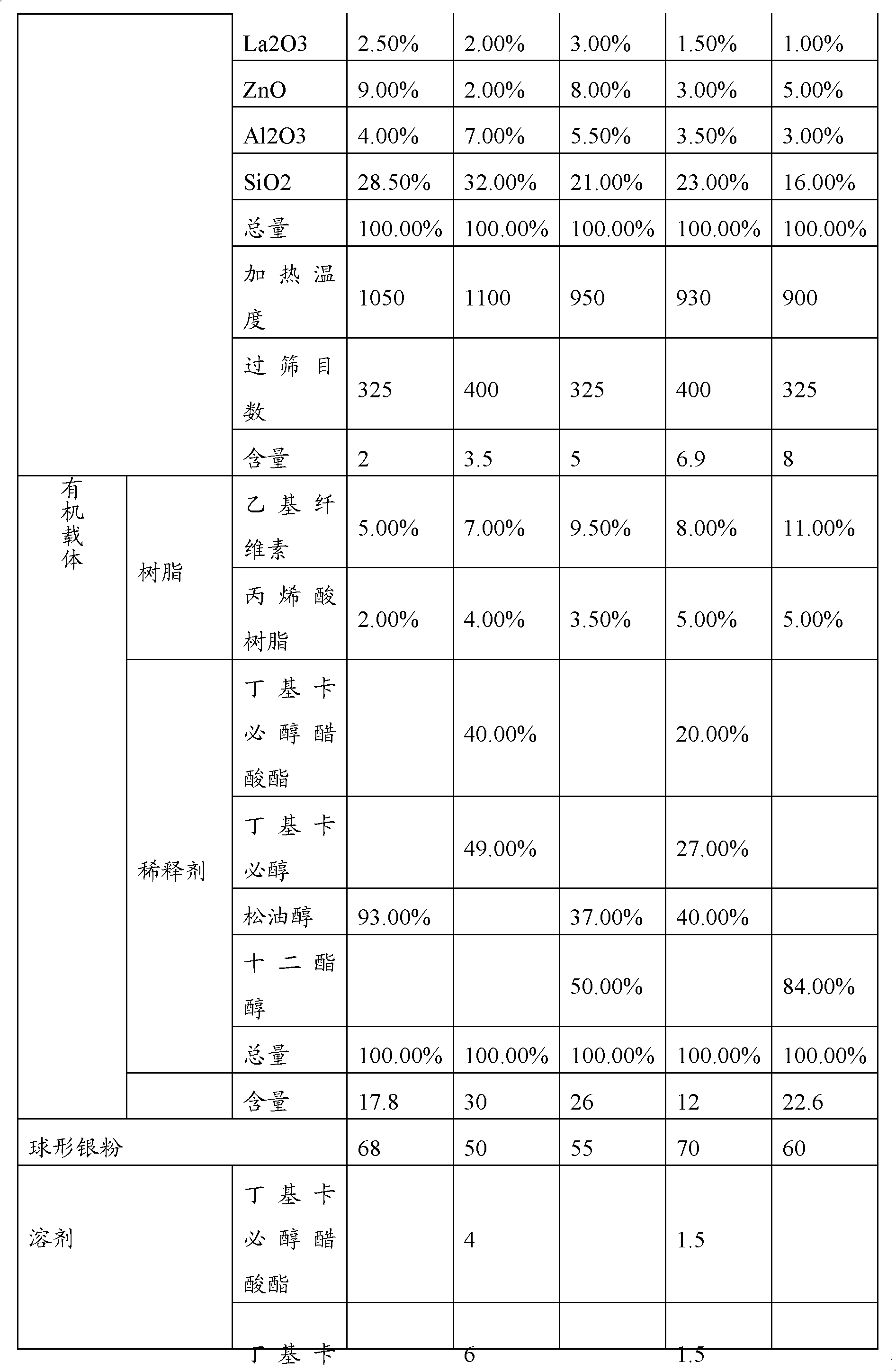

[0059] Using the raw materials and ratios shown in Table 1, according to the preparation method of Example 1, the back silver paste for solar cells was prepared.

[0060] Table 1 Raw materials and process conditions used in Examples 1 to 5 of the present invention

[0061]

[0062]

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com