Solar cell rear panel and production method thereof

A solar cell and backplane technology, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve the problems of low service life and unfavorable processing of solar battery backplanes, and achieve improved overall mechanical properties, good adhesion, Good electrical insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

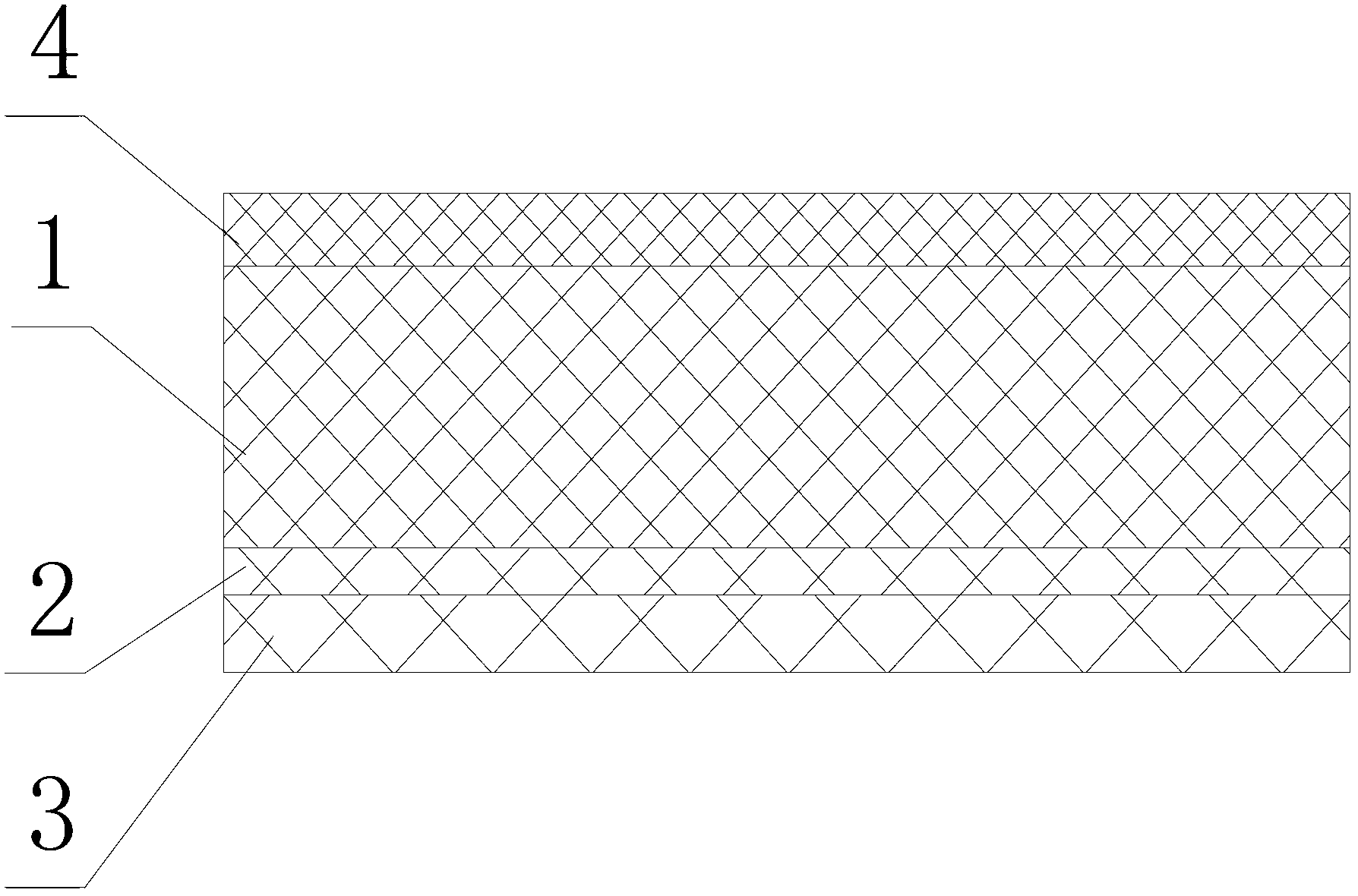

[0024] like figure 1 As shown, a solar battery back sheet includes a PET substrate 1, the front of the PET substrate 1 is coated with a layer of fluorine paint layer 4, and the reverse surface of the PET substrate 1 is provided with a modified surface that is pasted by an adhesive layer 2. The polyvinyl chloride film layer 3, the thickness of the modified polyvinyl chloride film layer 3 is 23-28 μm, which provides better mechanical properties, electrical insulation properties, water vapor barrier properties and weather resistance for the backplane, and the fluorine coating Layer 4 has a thickness of 20-30 μm, good light resistance and weather resistance, and can block the entry of water vapor and air. The thickness of the adhesive layer 2 is 8-12 μm, which is easy to bond, has good bonding effect, and is reliable. Good reliability, the thickness of the PET substrate 1 is 245-265 μm, good reliability and good practical performance, the adhesive layer 2 is polyurethane, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com