Preparation method for magnetic cellulose-chitosan composite microsphere

A technology of composite microspheres and cellulose, which is applied to the magnetism of organic materials/organic magnetic materials and the production of bulk chemicals. It can solve problems such as difficult large-scale application and difficult recycling, and achieves simple preparation methods and simple dissolution processes. , Ease of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

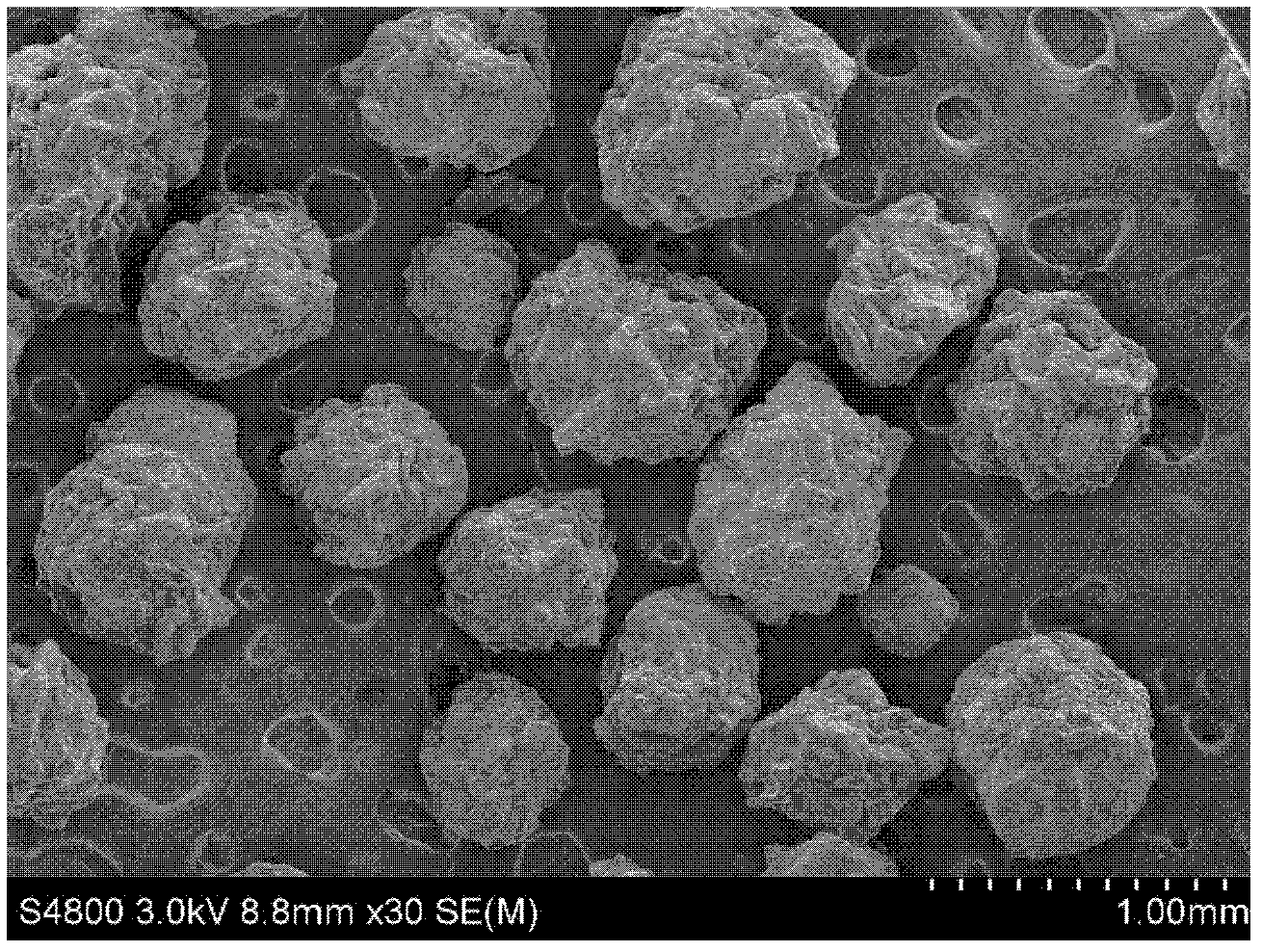

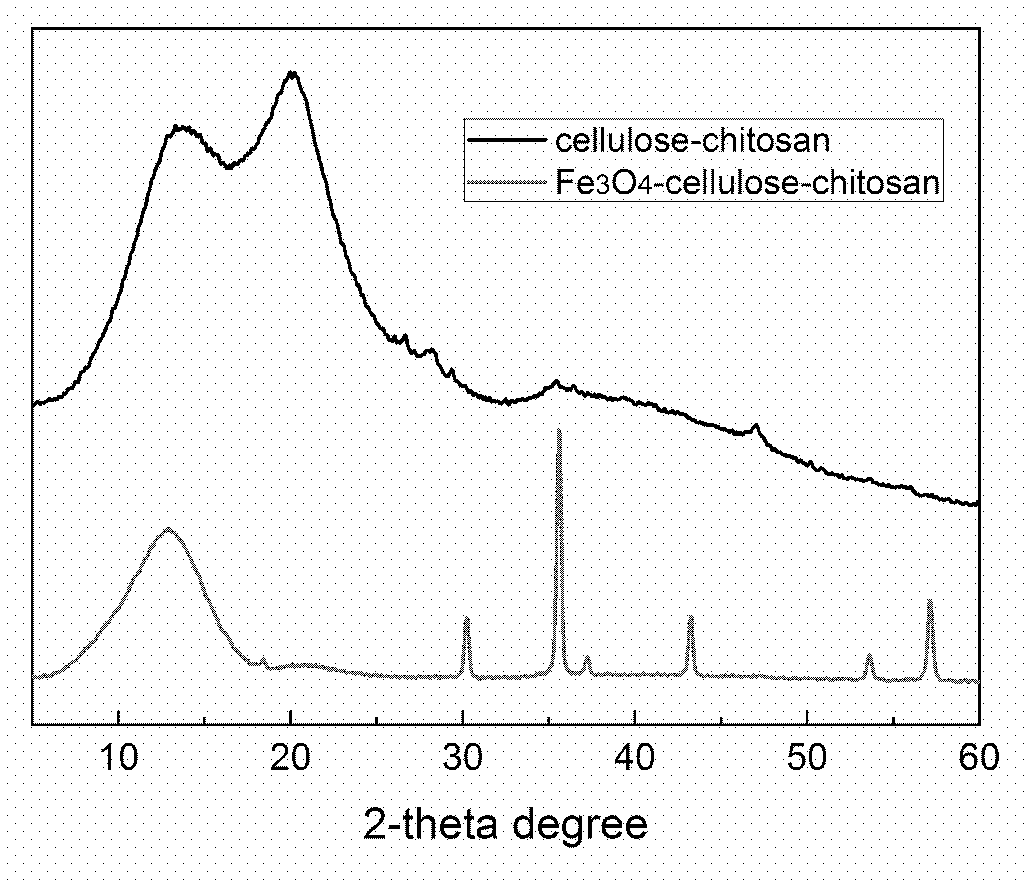

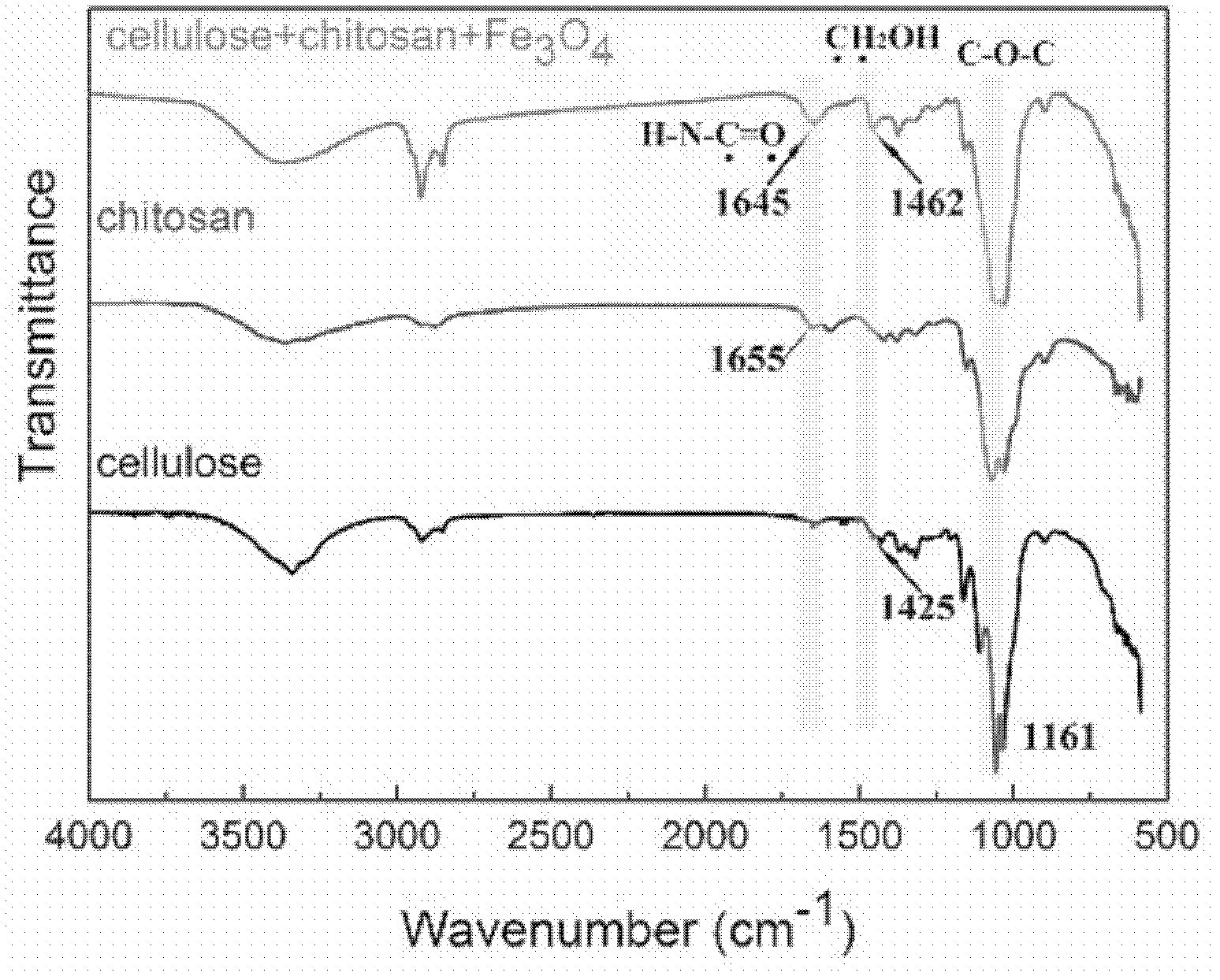

[0026] Add 0.7g cotton cellulose and 0.35g chitosan to 20g 1-butyl-3-methylimidazolium chloride (bmimCl) solution, heat the solution to 90°C and stir for 2 hours to completely dissolve the cellulose chitosan , a viscous white mixture was obtained. Add 0.35g of iron powder into the above viscous solution, continue to stir and react for 20 minutes, so that the iron powder particles are evenly dispersed in the solution, and then stop stirring. Pour the solution into a 250mL flask while it was hot, then add 100mL of vacuum pump oil and 0.5g of sorbitan oleate and stir at 100°C for 4h. The mechanical stirring rate was 1000rpm. Then it was lowered to room temperature, and deionized water was added dropwise to the above system while stirring, and stirring was continued for 1 h after the dropwise addition was completed to form microspheres. The reacted solution was poured into a 1L beaker and washed 5 times with deionized water by magnetic separation and pouring. The washed microsph...

Embodiment 2

[0028] Add 0.8g of paper pulp and 0.8g of chitosan to 15g of 1-ethyl-3-methylimidazole acetate (EmimOAc) solution, heat the solution to 80°C and stir for 1h to completely dissolve the cellulose chitosan , a viscous white mixture was obtained. 0.8g Fe 3 o 4 Particles were added to the above viscous solution, and the stirring reaction was continued for 20 minutes to make the Fe 3 o 4 The particles are evenly dispersed in the solution, and then the stirring is stopped. Pour the solution into a 250mL flask while it was hot, then add 200mL polyethylene glycol and 0.5g polyoxyethylene abietic acid, stir and react at 90°C for 20min. The mechanical stirring speed is 500rpm. Then it was lowered to room temperature, and ethanol was added dropwise to the above system while stirring, and stirring was continued for 1 h after the dropwise addition was completed to shape the microspheres. The reacted solution was poured into a 1L beaker and washed 5 times with ethanol by magnetic separa...

Embodiment 3

[0033]Add 0.4g microcrystalline cellulose and 1g chitosan to 30g 1-allyl-3-methylimidazolium chloride (AmimCl) solution, heat the solution to 110°C and stir for 0.5h to make the cellulose chitosan Dissolved completely to give a viscous white mixture. Add 0.2g of CoO particles into the above viscous solution, continue to stir and react for 30min, so that the CoO particles are evenly dispersed in the solution, and then stop stirring. Pour the solution into a 250mL flask while it is hot, add 100mL polypropylene glycol and 0.2g diglycerin polypropylene glycol ether, and stir the reaction at 110°C for 20min. The mechanical stirring rate is 2000rpm. Then it was lowered to room temperature, and acetone was added dropwise to the above system while stirring, and the stirring was continued for 2 hours after the dropwise addition was completed to shape the microspheres. The reacted solution was poured into a large beaker and washed 5 times with acetone by magnetic separation and pouring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com