Method for screening natural gas biological desulphurization flora

A technology for biological desulfurization and screening methods, applied in biochemical equipment and methods, microorganisms, microorganisms, etc., can solve the problems of sulfide tolerance and pressure domestication not yet involved, easy to ignore growth target bacteria, and high work intensity. The effect of small workload, short cycle and accelerated growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

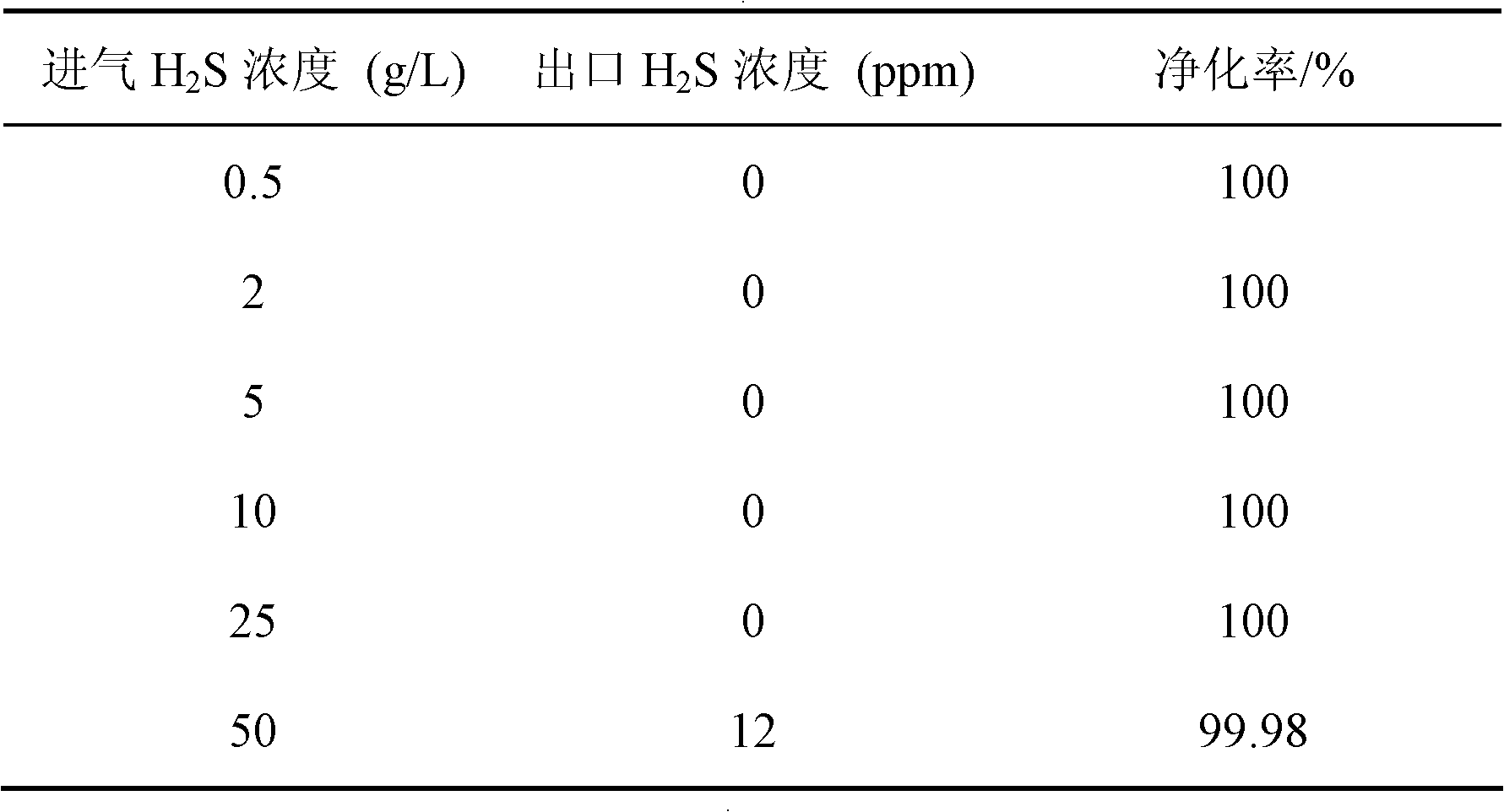

Embodiment 1

[0018] Screening of natural gas biological desulfurization bacteria in sulfur-contaminated soil:

[0019] Take the sulfur-contaminated soil (15-20cm) near the sulfur recovery unit of the natural gas purification plant, pass it through a 60-mesh sieve, add 5g of the sieved fine-grained soil sample into an anaerobic culture bottle filled with inorganic nutrient solution, and conduct anaerobic culture The bottle was placed on a constant temperature magnetic stirrer, and an external mixed gas source was connected. The culture temperature was 35°C, and the culture was stirred for 7 days. The composition of the inorganic nutrient solution includes carbon source, nitrogen source and buffer ion. The gas mixture composition is: 80% N 2 +20%CO 2 .

[0020] Add the culture solution into a sealed pressure-resistant container with an equal volume and a concentration of 0.04g / L NaHS, fill it with nitrogen to a pressure of 2MPa, and after standing still for 2 days, transfer it to a cultu...

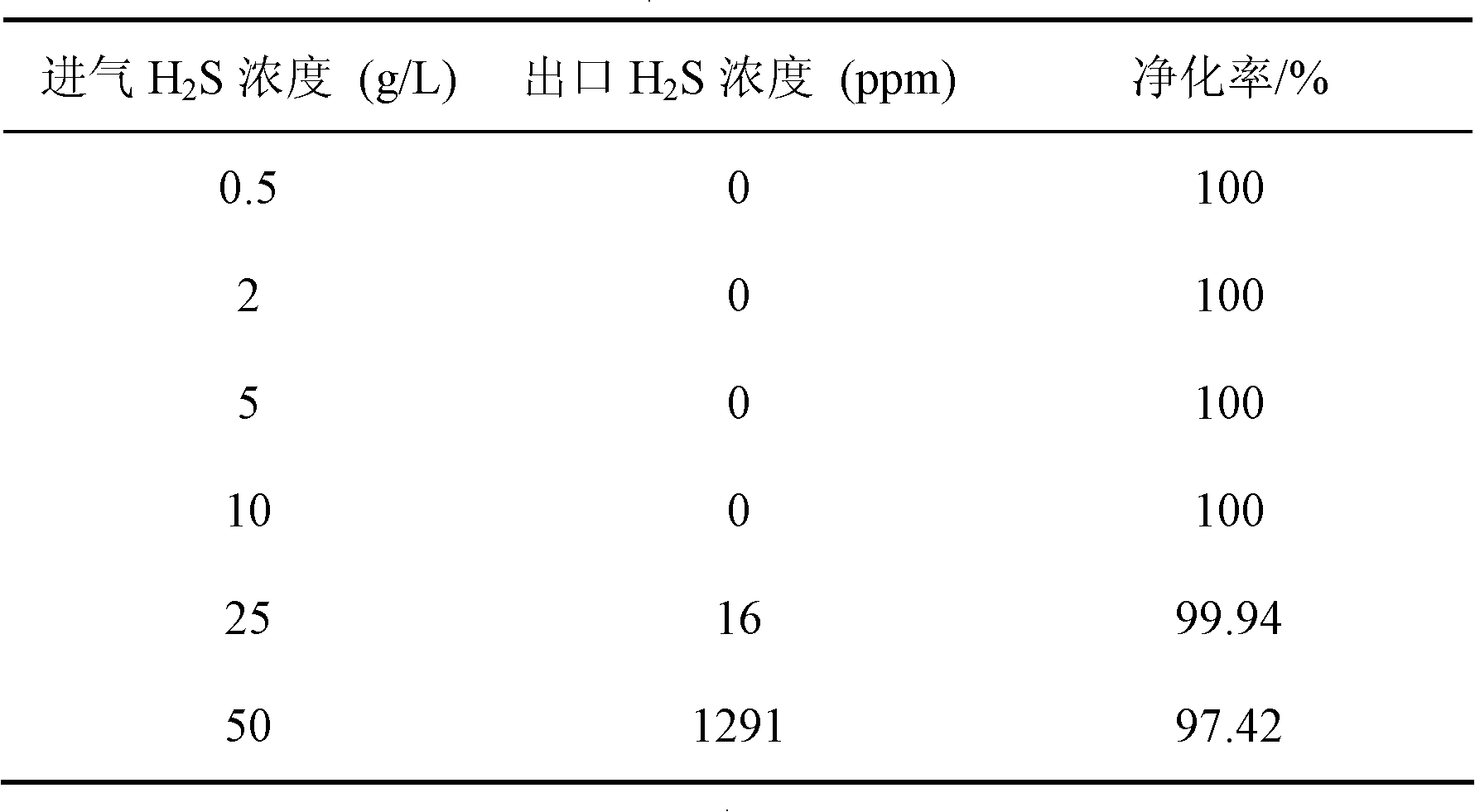

Embodiment 2

[0025] Screening of desulfurization bacteria in activated sludge in sewage treatment section of natural gas purification plant:

[0026] Take the activated sludge from the sewage treatment section of the natural gas purification plant, centrifuge it at 10,000rpm for 15 minutes, and then take an appropriate amount of sediment and add it to an anaerobic culture bottle filled with inorganic nutrient solution. The anaerobic culture bottle is placed on a constant temperature magnetic stirrer and connected to a mixed gas source. The culture temperature is 35°C, and the stirring culture is 7

[0027] d. The composition of the inorganic nutrient solution is as follows: wherein the composition of the inorganic nutrient solution includes carbon source, nitrogen source and buffer ion. The gas mixture composition is: 90% N 2 +10%CO 2 .

[0028] Add the culture solution into a sealed pressure-resistant container with an equal volume and a concentration of 0.04g / L NaHS, fill it with nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com