Sample preparation method for fracture of tungsten carbide coating on magnesium-alloy surface via scanning electron microscope

A technology of surface carbonization and scanning electron microscopy, which is applied in the preparation of test samples, etc., can solve the problems of affecting the observation effect of coating and substrate, too much interference of experimental data, and too large difference in hardness, so as to facilitate shape analysis and testing, The effect of no pollution shielding and less consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

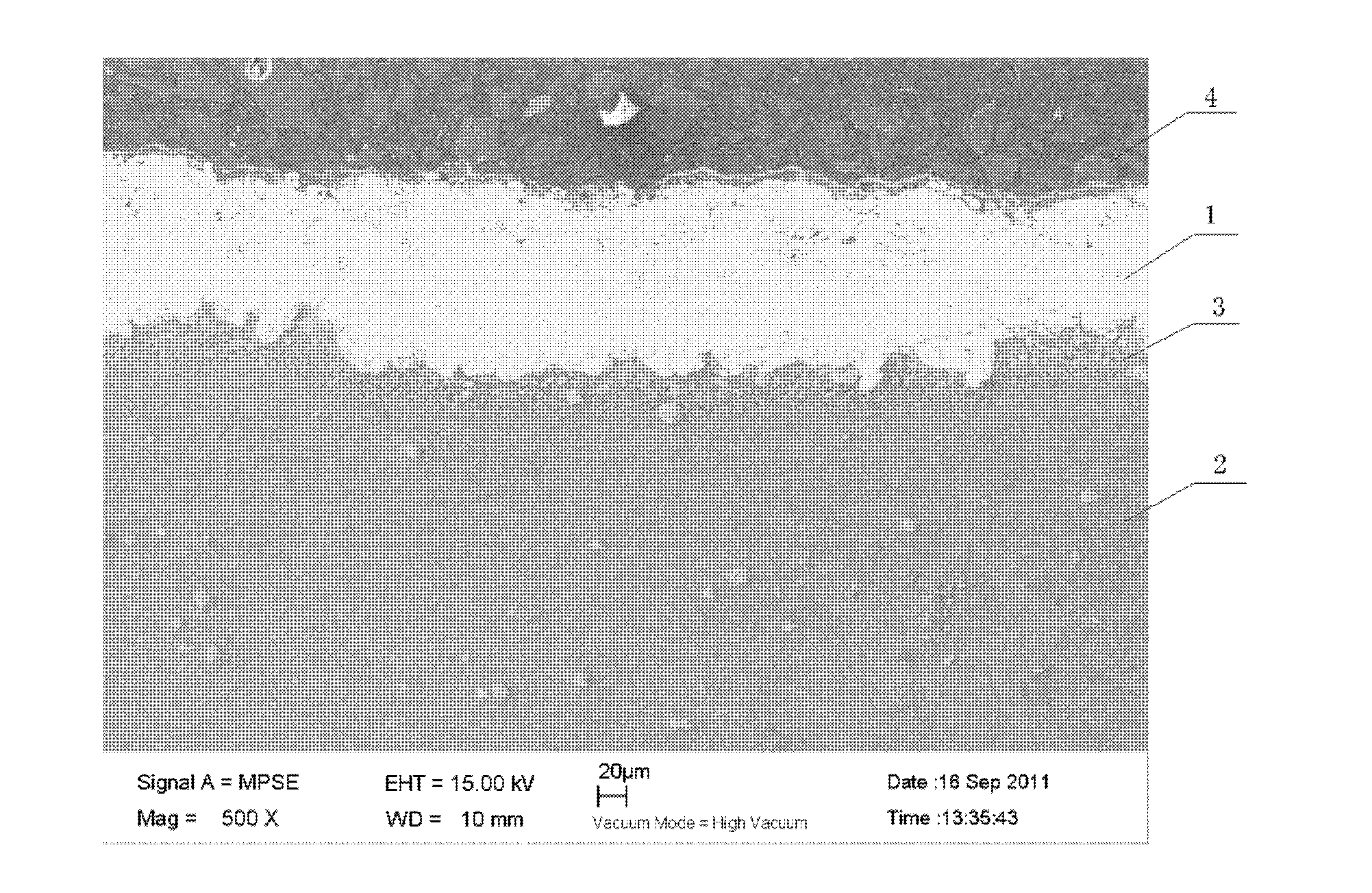

[0023] Embodiment: A scanning electron microscope sample preparation method of a tungsten carbide coating fracture on the surface of a magnesium alloy is characterized in that its specific steps are as follows:

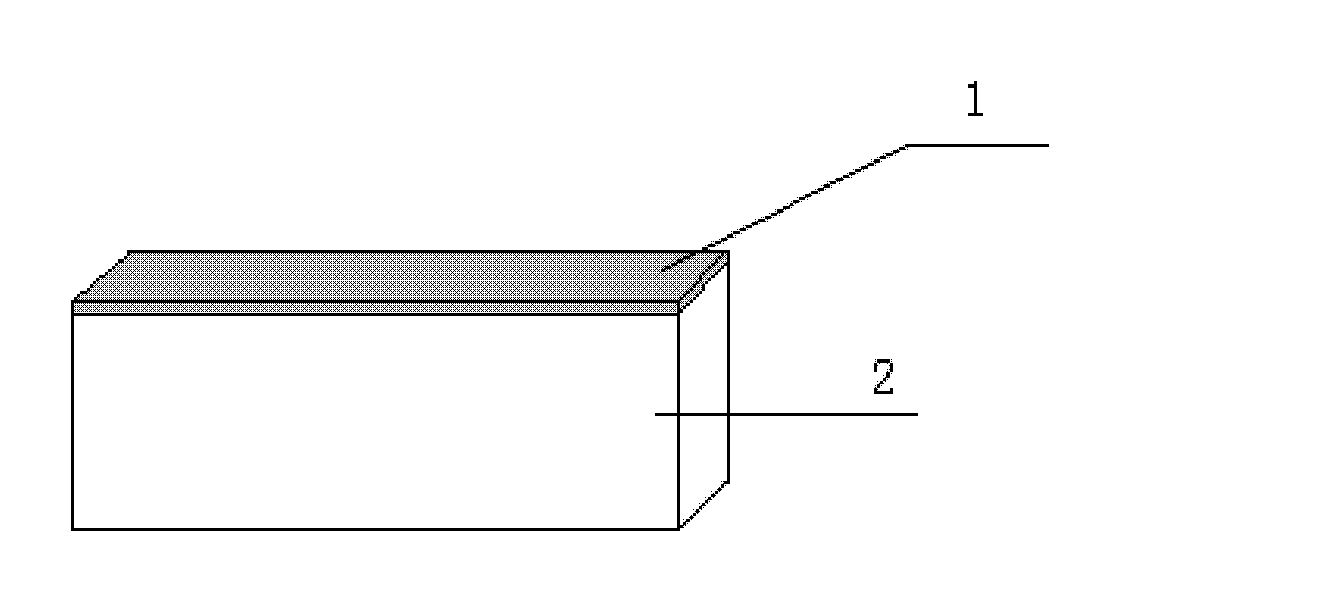

[0024] (1) Get a magnesium alloy sample with a tungsten carbide coating 1 on the surface of the magnesium alloy substrate 2;

[0025] (2) Due to the relatively small size of the sample chamber of the scanning electron microscope, a small-sized magnesium alloy sample should be obtained first, and the magnesium alloy sample should be cut into 5 mm wide, 30 mm long, and 10 mm high samples with a low-speed diamond circular saw. cuboid;

[0026] (2) Fine cutting: Cut the magnesium alloy substrate 2 along a direction parallel to the coating with a high-precision cutting device to obtain a magnesium alloy sheet sample with a tungsten carbide coating 1, the thickness of the magnesium alloy sheet sample is 2mm;

[0027] (3) Cut out a notch 5 at the relative positions of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com