Fresh water generation method and fresh water generation device

A water-making and raw water technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve semi-permeable membrane pollution, cannot fully inhibit microbial proliferation, and cannot fully solve water permeability reduce problems, achieve the effect of cost reduction and prevention of oxidation deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

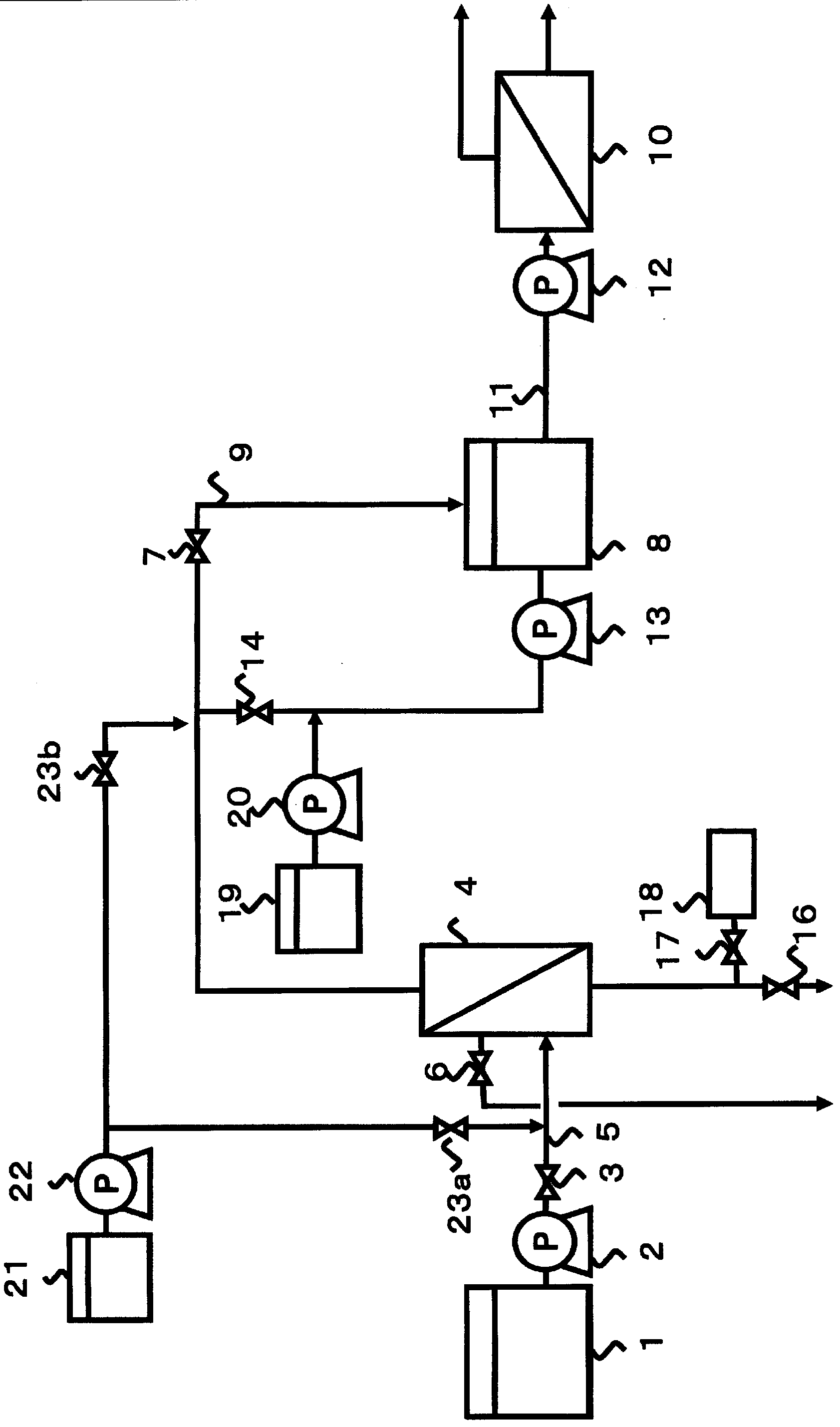

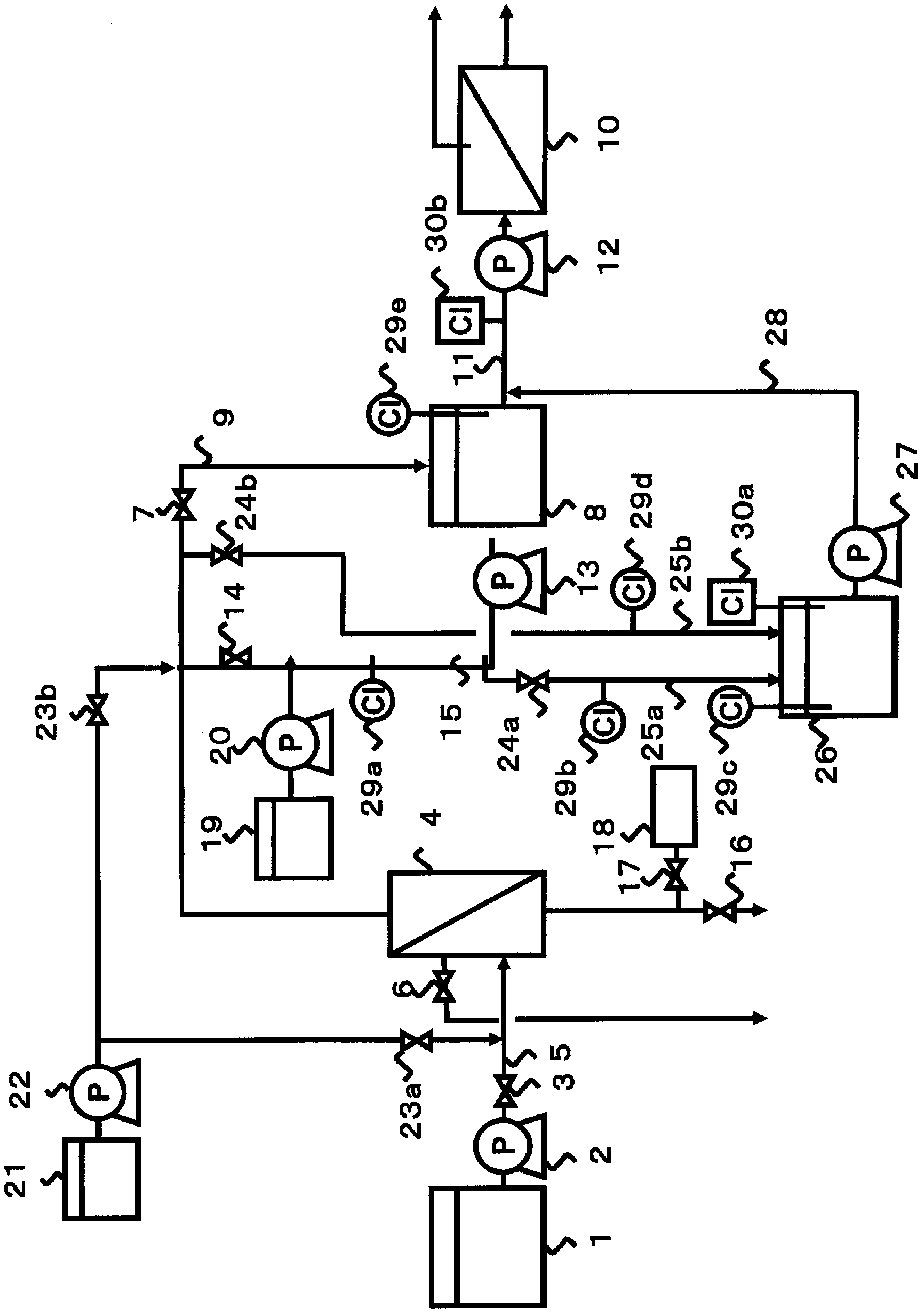

[0084] use figure 1 The apparatus of the structure shown makes water.

[0085] That is, as the hollow fiber membrane module 4, one pressurized hollow fiber membrane module (HFU-2020) manufactured by Toray Co., Ltd. and having a molecular weight cut-off of 150,000 Da was used. hollow fiber UF membrane made of polyvinylidene fluoride, and the membrane area is 72m 2 , open the raw water supply valve 3 and the filter water valve 7, make the raw water supply pump 2 operate, and filter the seawater with a turbidity of 4 degrees, a TOC (Total Organic Carbon: total organic carbon) concentration of 2 mg / L, and a salt concentration of 3.5%. 3m / d for full filtration. In addition, as the semipermeable membrane unit 10, four polyamide reverse osmosis membrane units (TM820-400) manufactured by Toray Co., Ltd. were used, and the membrane filtration flow rate was 60 m 3 / d, concentrated water flow rate 120m 3 Filter under the condition of / d, recovery rate 33%.

[0086] During this perio...

Embodiment 2

[0092] Instead of ammonium chloride in Example 1, taurine as an amino-containing compound was added to raw water at 2.5% by weight, and then supplied to the semipermeable membrane unit 10 . Other than that, it carried out similarly to Example 1.

[0093] As a result, the transmembrane pressure difference of the hollow fiber membrane module 4 was 35 kPa immediately after the start of operation, but it was about 65 kPa two months later, and relatively stable operation was possible without chemical cleaning. In addition, the desalination rate of the semi-permeable membrane unit 10 was 99.7% immediately after the start of the operation, whereas it was 99.4% two months later, and was steadily changing. The transmembrane pressure difference of the semipermeable membrane unit 10 was 100 kPa immediately after the start of the operation, but was stable at about 130 kPa two months later.

Embodiment 3

[0095] One of the 24 steps performed from the back pressure cleaning step to the usual filtration step in Example 1 is carried out according to the following [step a], and the remaining 23 times are carried out according to the following [step b]. , carried out in the same manner as in Example 1.

[0096] [Process a]

[0097] (a-1) Simultaneously implement back pressure cleaning and air cleaning for 1 minute, the back pressure cleaning is carried out using water containing chlorine agent, and the water containing chlorine agent is added to the membrane filtration water of hollow fiber membrane module 4 The sodium hypochlorite in the chlorine agent storage tank 19 is obtained, and then the hollow fiber membrane module 4 is immersed in water containing the chlorine agent for 20 minutes. The free chlorine concentration in the back pressure washing water at this time was adjusted to 100 mg / L.

[0098] (a-2) After that, the drain valve 16 is opened to drain all the chlorine-conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com