Zinc sulfide-benzoic acid nano composite photocatalytic material and preparation method thereof

A technology of nanocomposite materials and photocatalytic materials, which is applied in the field of zinc sulfide and benzoic acid nanocomposite photocatalytic materials and its preparation, can solve the problems of increasing cost and complexity, and achieve improved photocatalytic efficiency, simple preparation process, and production easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

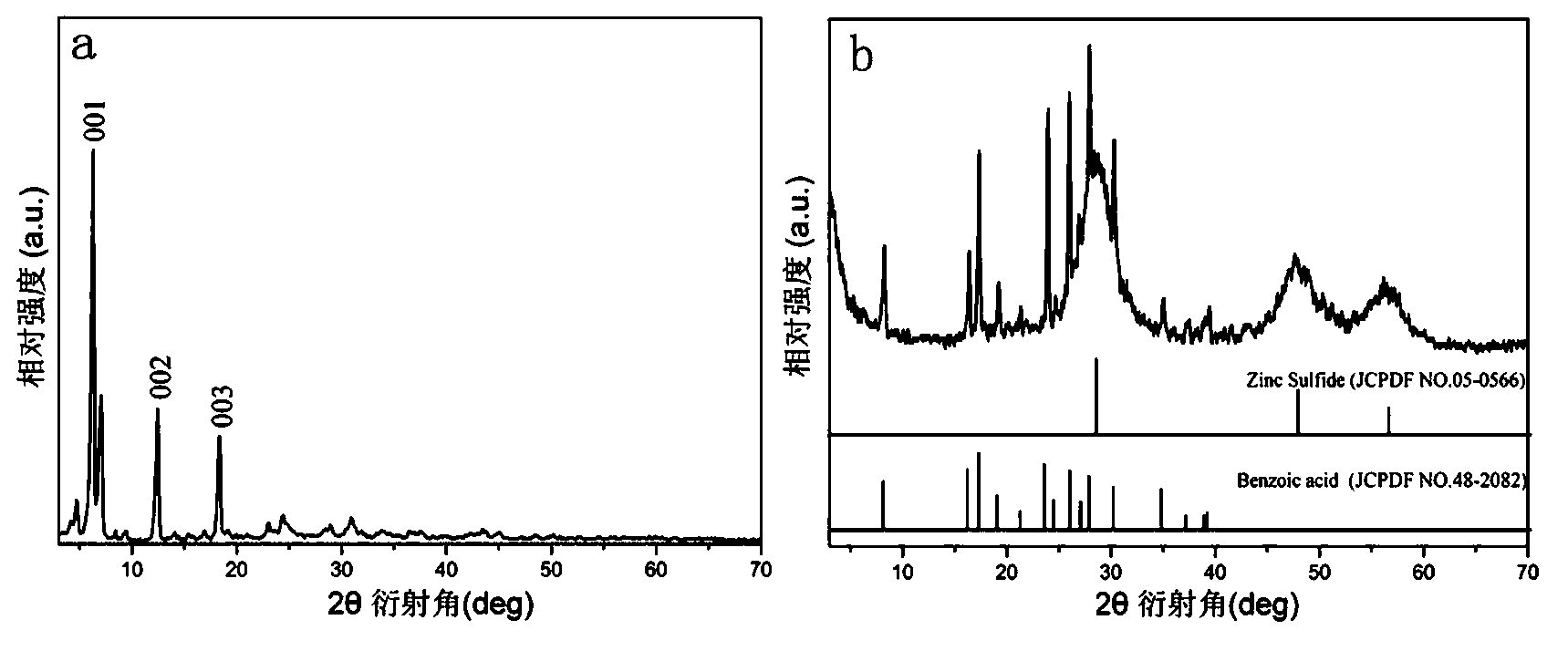

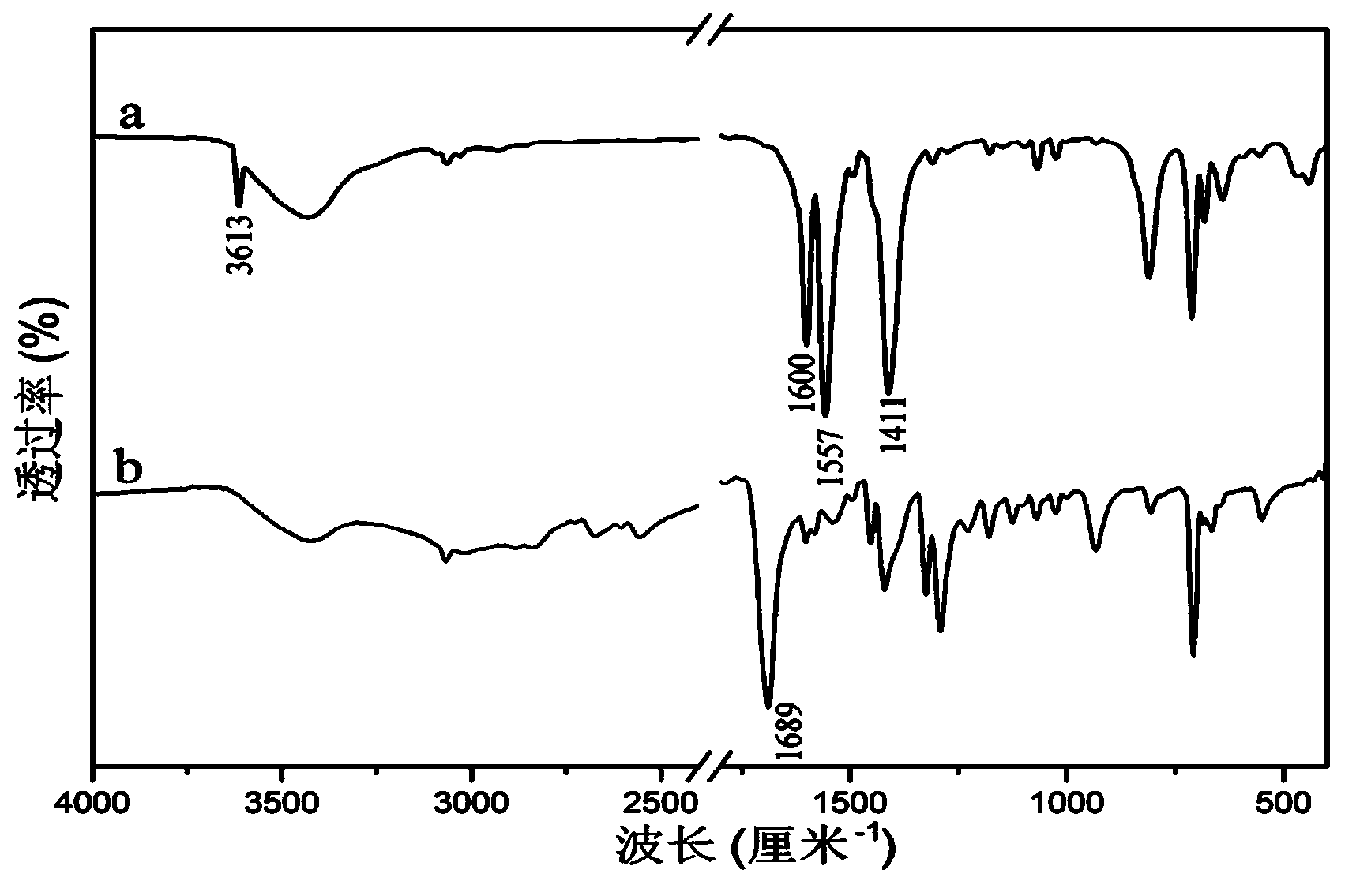

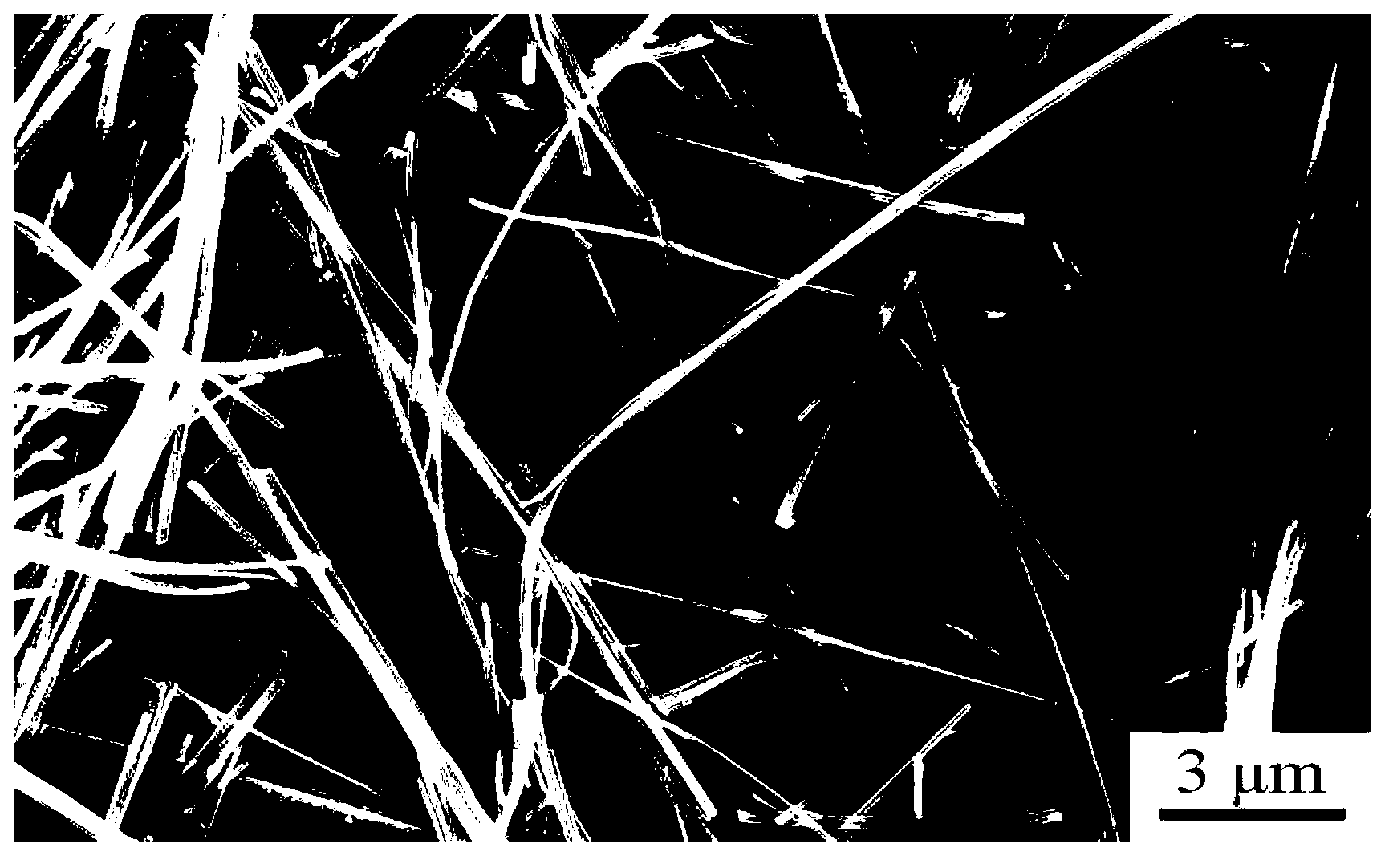

Embodiment 1

[0030] 1) Weigh 11.90g Zn(NO 3 ) 2 ·6H 2 O and 5.76 g of sodium benzoate were dissolved in 100 mL at room temperature to remove CO 2 Prepare the salt solution with water, pour the prepared two salt solutions into a four-neck flask, and start to rotate at a constant speed with an electric stirrer to mix the salt solution evenly;

[0031] 2) Weigh 2g NaOH and dissolve in 100mL to remove CO 2 Prepare lye in water, slowly add lye to the mixed salt solution, and white precipitates will appear in the solution, adjust the pH of the solution to 6, raise the temperature to 90°C, and react at this temperature for 24 hours. After the reaction, The precipitate was taken out, centrifuged and used to remove CO 2 After washing with water for 4 times, the product was dried at 50° C. for 6 hours to obtain a one-dimensional benzoate intercalated layered zinc hydroxide nanofiber precursor;

[0032] 3) Place the benzoate-intercalated layered zinc hydroxide nanofiber precursor prepared in step ...

Embodiment 2

[0041] 1) Weigh 11.90g Zn(NO 3 ) 2 ·6H 2 O and 5.76 g of sodium benzoate were dissolved in 100 mL at room temperature to remove CO 2 Prepare a salt solution in the water, pour the prepared two salt solutions into a four-necked flask, and start to rotate at a constant speed with an electric stirrer to mix the salt solution evenly;

[0042] 2) Weigh 2g NaOH and dissolve in 100mL to remove CO 2 Prepare lye in water, slowly add lye to the mixed salt solution, and white precipitates will appear in the solution, adjust the pH of the solution to 7, raise the temperature to 90°C, and react at this temperature for 24 hours. After the reaction, The precipitate was taken out, centrifuged and used to remove CO 2 Washing with water for 3 times, drying the product at 50°C for 6 hours to obtain a two-dimensional benzoate intercalated layered zinc hydroxide nanosheet precursor;

[0043] 3) Place the benzoate-intercalated layered zinc hydroxide nanosheet precursor prepared in step 2) in t...

Embodiment 3

[0047] 1) Weigh 5.95g Zn(NO 3 ) 2 ·6H 2 O and 5.76 g of sodium benzoate were dissolved in 100 mL at room temperature to remove CO 2 Prepare a salt solution in water, pour the prepared two salt solutions into a four-neck flask, and start to use an electric stirrer to rotate at a constant speed to mix the salt solution evenly;

[0048] 2) Weigh 0.6g NaOH and dissolve in 100mL to remove CO 2 Prepare lye in water, slowly add lye to the mixed salt solution, and white precipitates will appear in the solution, adjust the pH of the solution to 6, raise the temperature to 100°C, and react at this temperature for 18 hours. The precipitate was taken out, centrifuged and used to remove CO 2 After washing with water for 4 times, the product was dried at 50° C. for 6 hours to obtain a one-dimensional benzoate intercalated layered zinc hydroxide nanofiber precursor;

[0049] 3) Place the benzoate-intercalated layered zinc hydroxide nanofiber precursor prepared in step 2) in the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com