Tail gas circulating process in acrylic acid production by propane one-step method

A technology of tail gas circulation and acrylic acid, which is applied in the preparation of carboxylate, chemical instruments and methods, and the preparation of organic compounds, to achieve the effects of reducing consumption, ensuring yield, and enhancing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

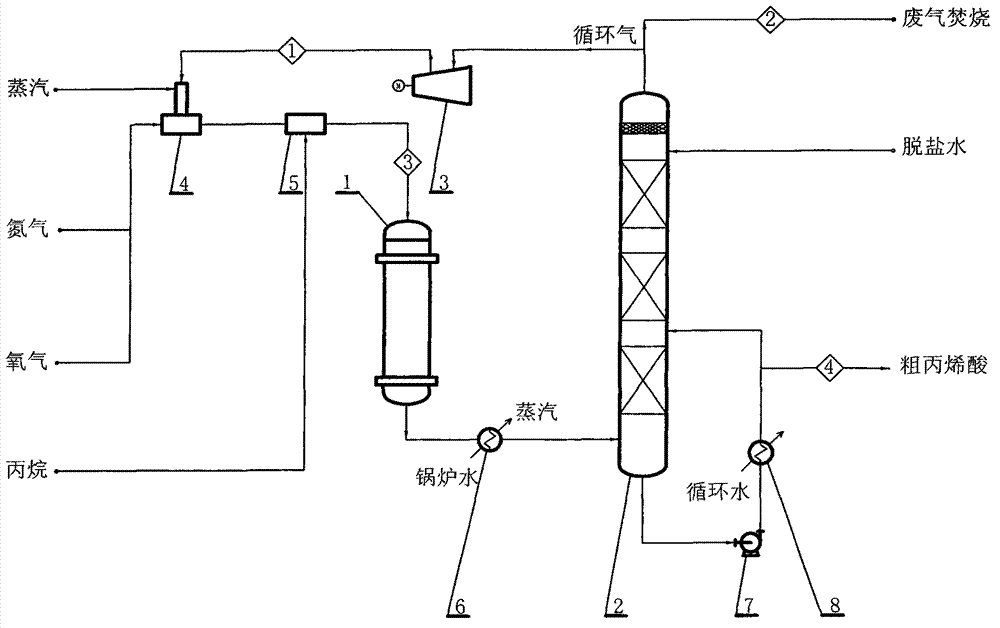

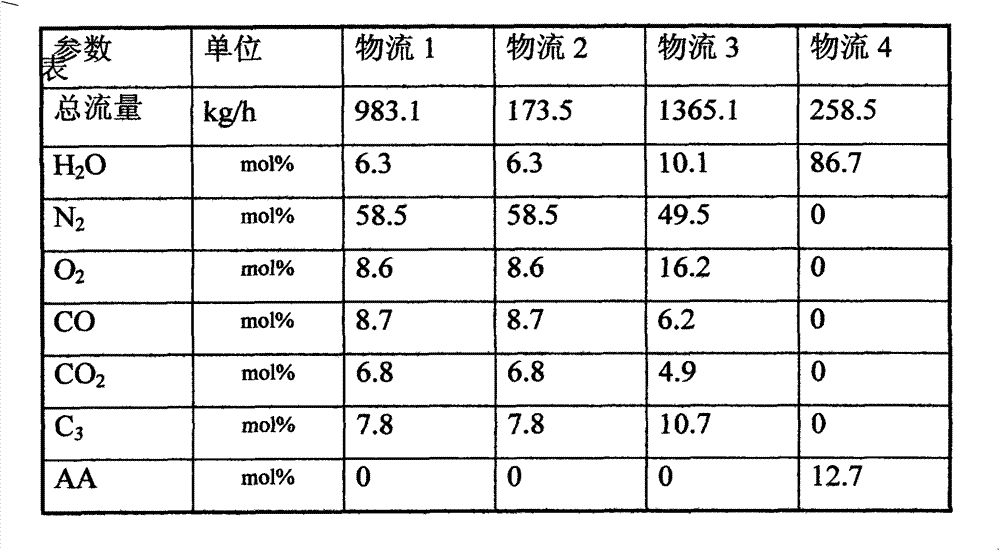

[0025] The stream number 1 in Fig. 1 is the tail gas circulation material, the stream number 2 is the top material of the absorption tower, the stream number 3 is the waste gas incineration material, the stream number 4 is the reactor feed, and the stream number 5 is the crude acrylic acid output.

[0026] Taking a medium-sized test device as an example, using the reaction tail gas circulation process, many tests have proved that most of the gas from the top of the washing tower 2 is used as the circulating gas, and it is better to send 80% to 90% of the circulating gas to the compressor 3. It is best to feed 85% of the circulating gas into the compressor 3, which not only avoids the composition of the reaction gas from being in the explosion range, but also makes full use of propane resources, ensuring a certain conversion rate.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com