Capillary column gas chromatography method for N-methyldiethanolamine decarbonizer component

A methyldiethanolamine decarburizing agent and gas chromatography analysis technology, which is applied in the field of capillary gas chromatography analysis, can solve the problems of not being able to simultaneously analyze MDEA and PIP at the same time, poor anti-interference ability, cumbersome pretreatment, etc. Accurate results and fast analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

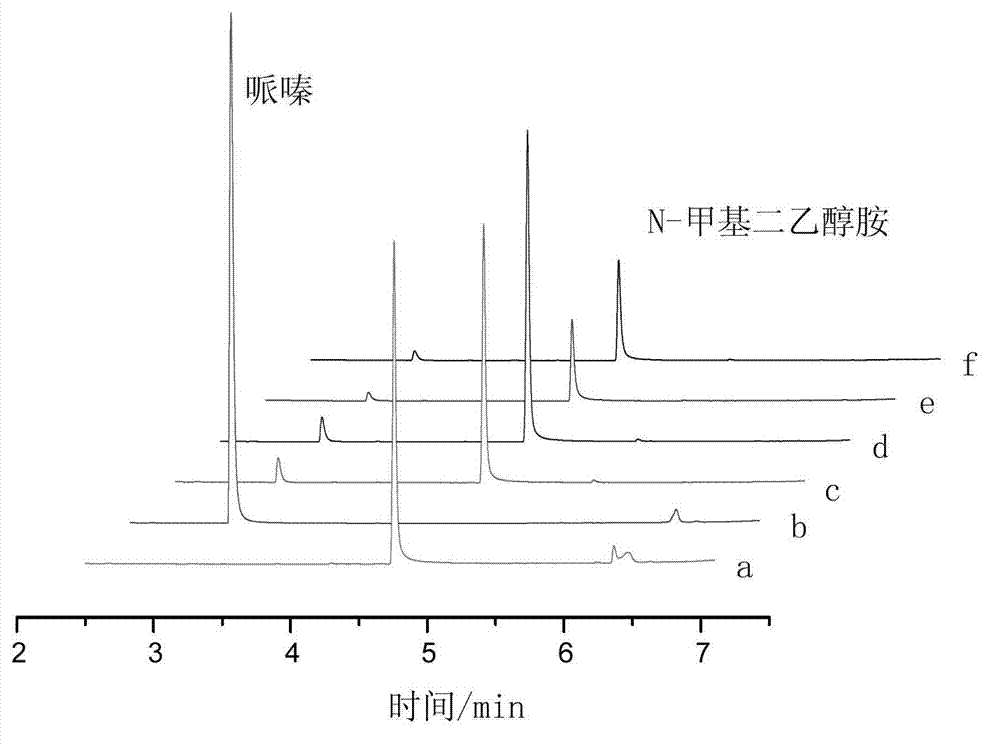

[0049] 1) Gas chromatography conditions:

[0050] Gas chromatograph: Shimadzu GC2010;

[0051] Chromatographic column: Rtx-5 capillary column (30m×0.25mm i.d×0.25μm);

[0052] Column temperature: 80°C, hold for 0min, then program temperature rise to 100°C at 10°C / min, hold for 0min; program temperature rise to 150°C at 20°C / min, hold for 0min; ℃, keep 0min;

[0053] Injection port temperature: 270°C;

[0054] Hydrogen flame ion detector temperature: 320°C;

[0055] Carrier gas: high-purity nitrogen;

[0056] Column flow rate: 1.03mL / min (constant flow);

[0057] Makeup flow rate: 30mL / min;

[0058] Hydrogen flow rate: 40mL / min;

[0059] Air flow rate: 400mL / min;

[0060] Split ratio: 49:1;

[0061] Injection volume: 1μL;

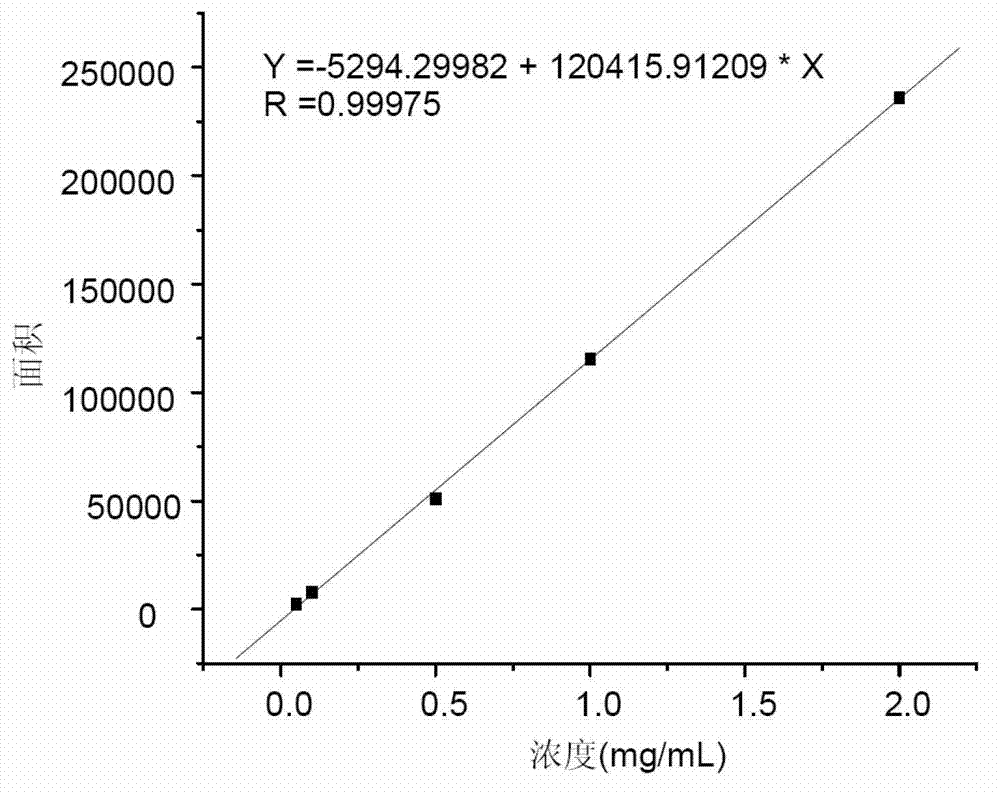

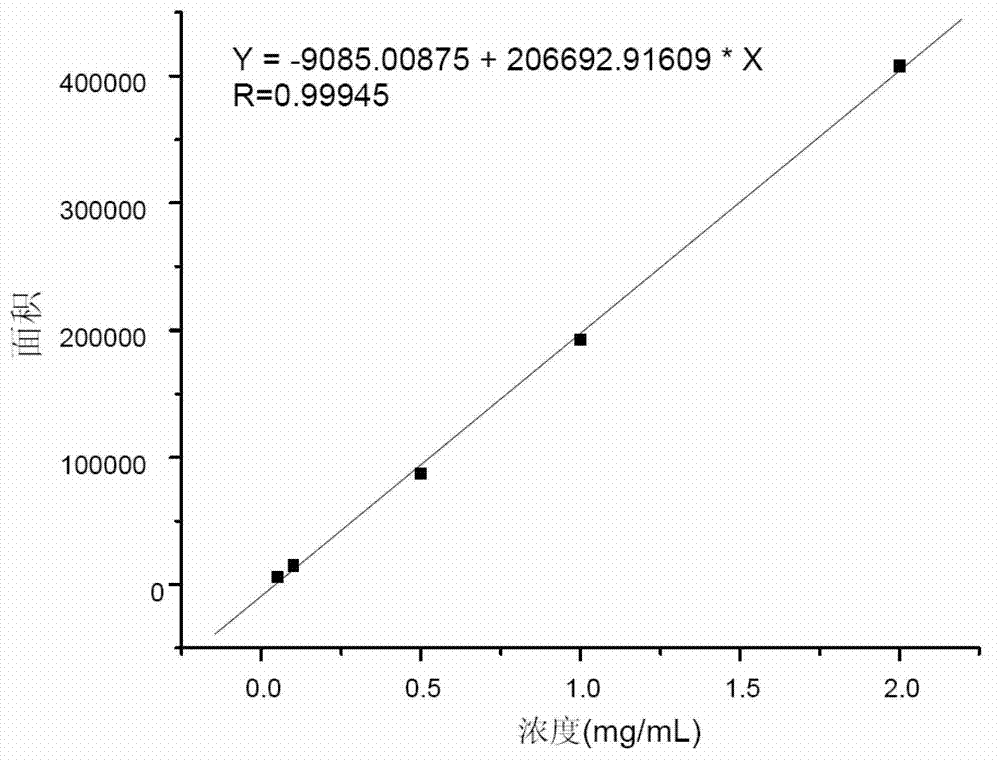

[0062] 2) Preparation of standard curves for N-methyldiethanolamine and piperazine: Accurately weigh 1.0000g of N-methyldiethanolamine and 1.0000g of piperazine in a beaker, and set the volume to 100mL as the standard stock solution. Standard stoc...

Embodiment 2

[0066] 1) Gas chromatography conditions:

[0067] Gas phase-mass spectrometer: Shimadzu GC-MS2010Plus;

[0068] Chromatographic column: DB-5 capillary column (30m×0.25mm i.d×0.25μm);

[0069] Column temperature: 80°C, hold for 0min, then program temperature rise to 100°C at 10°C / min, hold for 0min; program temperature rise to 150°C at 20°C / min, hold for 0min; ℃, keep 0min;

[0070] Injection port temperature: 270°C;

[0071] Mass spectrometry conditions: EI ion source, temperature 200°C; electron energy: 70eV; scan mode: full scan mode, scan range m / z: 10-510, database: NIST27.LIB, WILEY7.LIB;

[0072] Carrier gas: high-purity nitrogen;

[0073] Column flow rate: 1.03mL / min (constant flow);

[0074] Makeup flow rate: 30mL / min;

[0075] Hydrogen flow rate: 40mL / min;

[0076] Air flow rate: 400mL / min;

[0077] Split ratio: 49:1;

[0078] Injection volume: 1μL;

[0079] 2) Preparation of standard curves for N-methyldiethanolamine and piperazine: Accurately weigh 1.0000g...

Embodiment 3

[0082] 1) Gas chromatography conditions:

[0083] Chromatograph: Agilent-7890A;

[0084] Chromatographic column: HP-5 capillary column (30m×0.25mm i.d×0.25μm);

[0085] Column temperature: 80°C, hold for 0min, then program temperature rise to 100°C at 10°C / min, hold for 0min; program temperature rise to 150°C at 20°C / min, hold for 0min; ℃, keep 0min;

[0086] Injection port temperature: 270°C;

[0087] Hydrogen flame ion detector temperature: 320°C;

[0088] Carrier gas: high-purity nitrogen;

[0089] Column flow rate: 1.03mL / min (constant flow);

[0090] Makeup flow rate: 30mL / min;

[0091] Hydrogen flow rate: 40mL / min;

[0092] Air flow rate: 400mL / min;

[0093] Split ratio: 49:1;

[0094] Injection volume: 1μL;

[0095] 2) Preparation of standard curves for N-methyldiethanolamine and piperazine: Accurately weigh 1.0000g of N-methyldiethanolamine and 1.0000g of piperazine in a beaker, and set the volume to 100mL as the standard stock solution. Standard stock solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com